Method for clearing shell side scale of shell and tube heater in monoammonium phosphate production on line

A tubular heater and heater technology, which is applied in the field of phosphate fertilizer production, achieves the effects of less investment, simple equipment configuration, and obvious descaling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

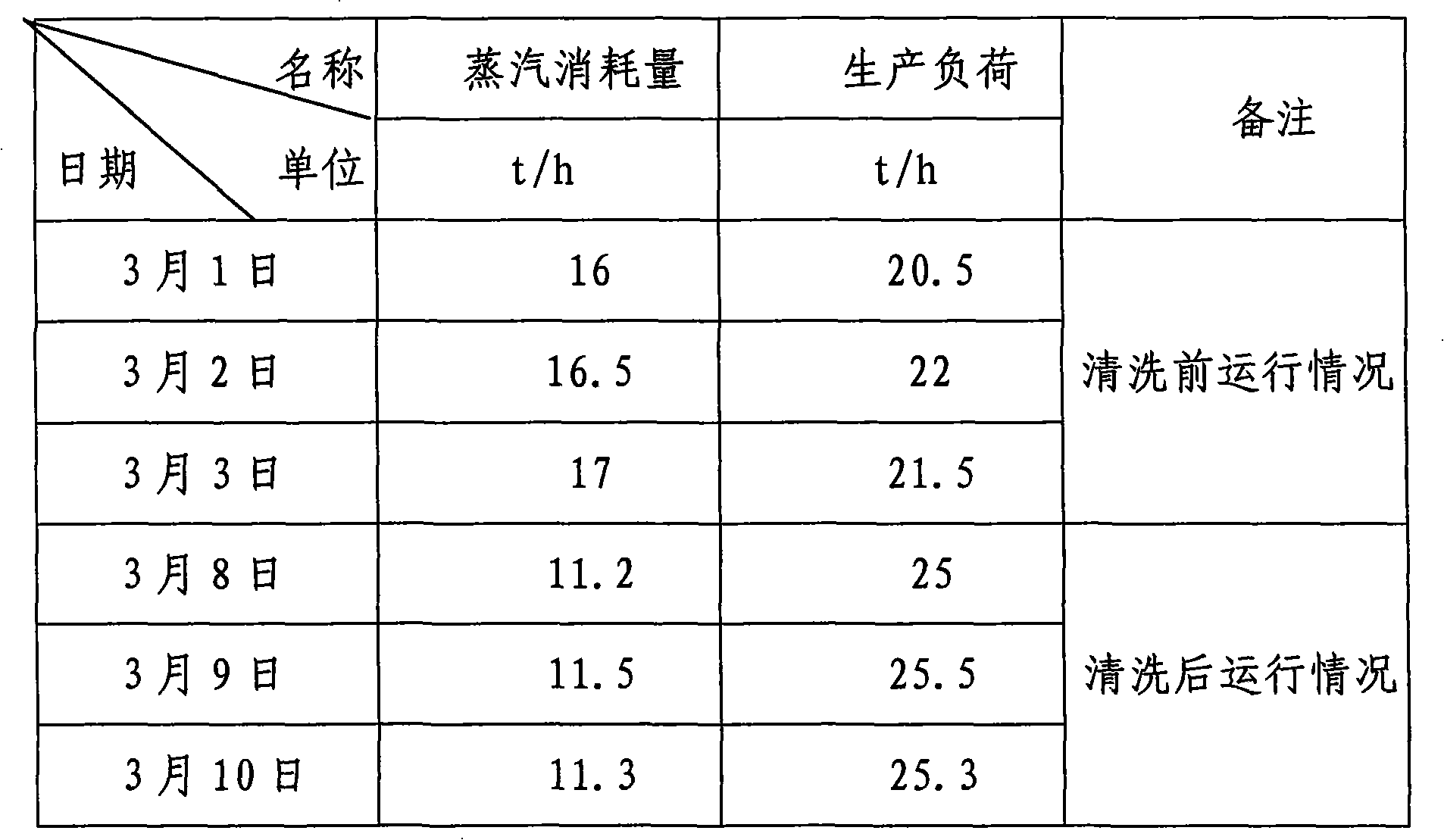

[0017] Wengfu (Group) Co., Ltd. Phosphate Fertilizer Plant's 480,000 tons / year powdered monoammonium phosphate plant has been explored for many years, and the shell side of the monoammonium phosphate plant heater is regularly cleaned online by chemical methods, and good results have been achieved.

[0018] The specific method is:

[0019] with P 2 o 5 30% phosphoric acid, 40% nitric acid, 98% sulfuric acid and 15% fluosilicic acid are prepared into 1 ton of cleaning solution according to the mass ratio of 5:3:1:1, put into a 1 ton bucket, and stir evenly.

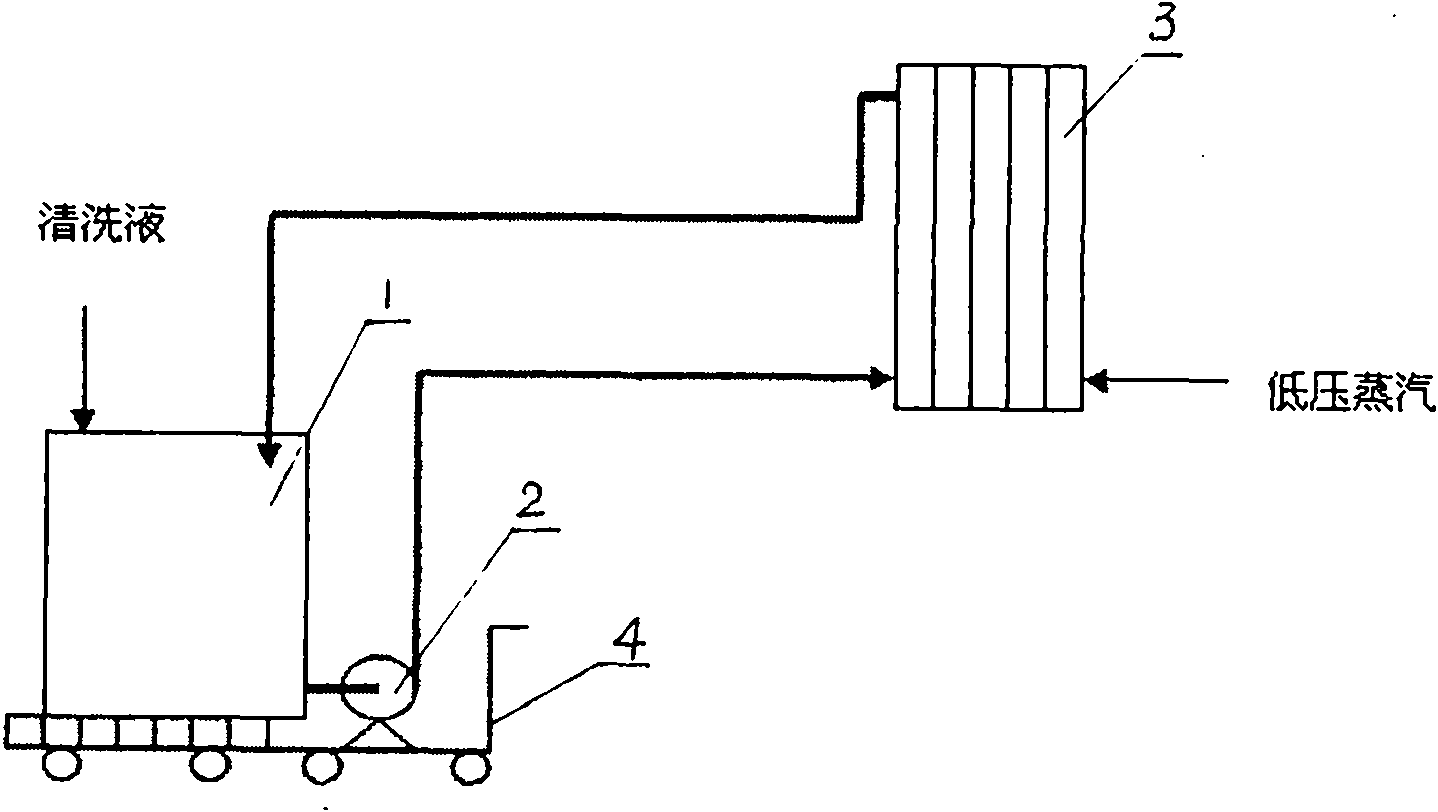

[0020] Use the 1t barrel as a cleaning circulation tank: the cleaning liquid outlet pipe is connected to the delivery pump, and placed on the mobile trolley. After the mobile trolley is close to the tube-and-tube heater that needs to be cleaned, it connects with the acid inlet at the lower part of the heater shell. Connection; the acid outlet on the upper shell side of the heater is connected to the barrel with a conduit....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com