Sorting mechanism for steam pressure air-entrapping panel

An autoclaved aeration, plate technology, applied in the direction of stone processing equipment, manufacturing tools, work accessories, etc., can solve the problems of difficult selection and heavy quality, and achieve the effect of good support, improved efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

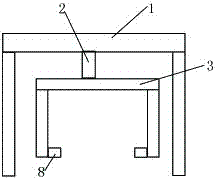

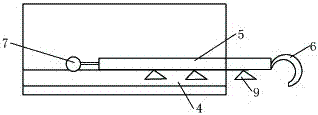

[0011] Combine below figure 1 and figure 2 Specific description embodiment:

[0012] The sorting mechanism for autoclaved and aerated plates includes a bracket 1. A hydraulic cylinder 2 is arranged on the bracket 1. The output end of the hydraulic cylinder 2 is connected with a lifting frame 3. Locking brackets are arranged at both ends of the lifting frame 3. Mechanism 8, the locking mechanism 8 includes a slide rail 4, the slide rail 4 is provided with a connecting rod 5, the front end of the connecting rod 5 is provided with a lock hook 6, the rear end of the connecting rod 5 is connected with a steering mechanism 7, and the connecting rod It can slide along with the slide rail. When locking is required, the two connecting rods will approach each other along with the slide rail, and then the front ends of the two connecting rods will extend into the plate frame under the plate, and the connecting rod will be locked by the steering mechanism. Turn so that the hook locks w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com