Double-station circumferential stitch welding device for heat exchanger

A heat exchanger, double station technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of multiple rework, difficult welding process, product quality discount, etc., to reduce the number of rework and save manpower and material resources , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

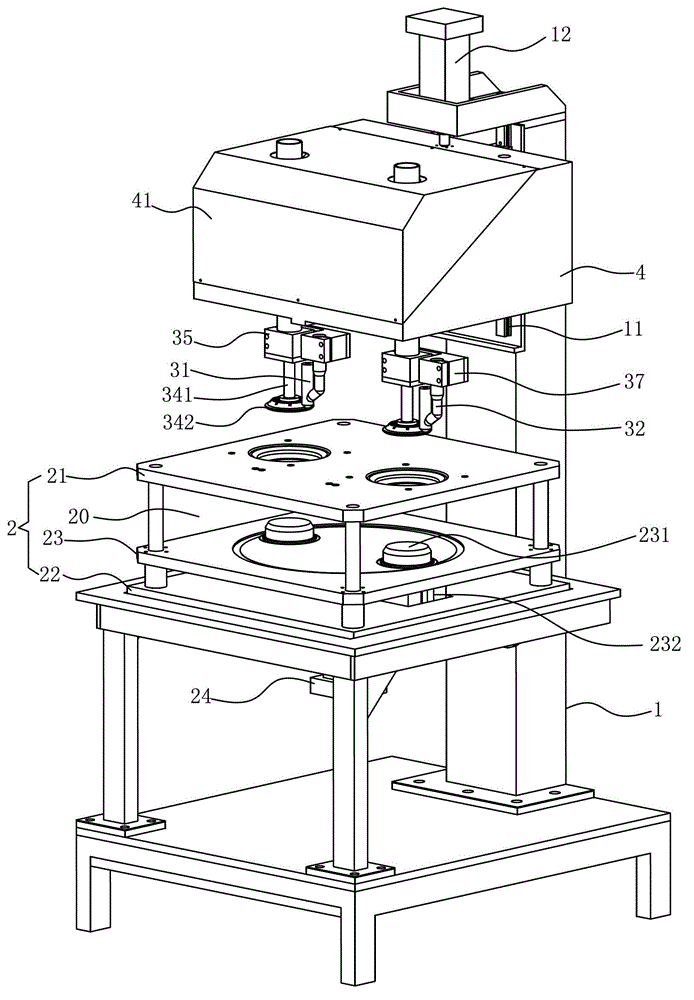

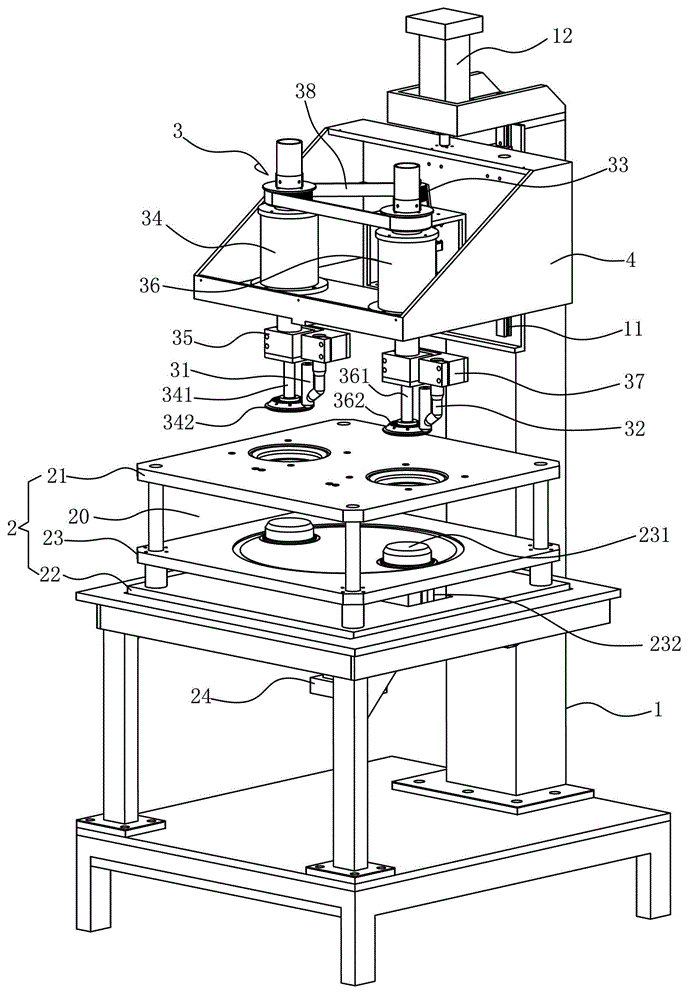

[0032] see Figure 1-7 As shown, the double-station circumferential seam welding equipment for heat exchangers includes: a frame 1, a jig 2 arranged on the frame 1 and used for positioning the plates of the heat exchanger, and a welding device for welding 3.

[0033] The frame 1 is equipped with a mounting table 4 that can move up and down in the frame 1 , and the welding device 3 is installed in the mounting table 4 . Specifically, the frame 1 is equipped with a slide rail 11 for assembling the installation table 4 and a first air cylinder 12 for driving the installation table 4 to move up and down in the slide rail 11 .

[0034] An outer cover 41 is installed on the installation platform 4 , and the outer cover 41 can effectively protect the welding device 3 installed in the installation platform 4 .

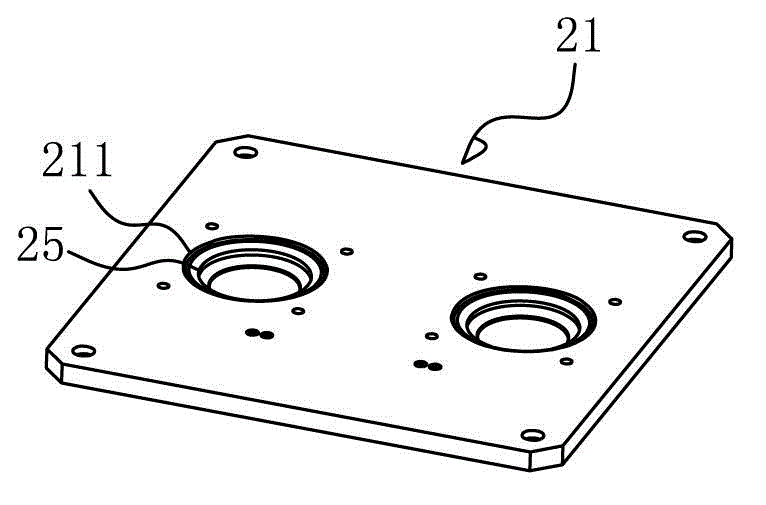

[0035] The jig 2 includes: upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com