Preparation method of sapphire-glass laminated sheet

A sapphire and glass layer technology, applied in the field of material processing, can solve the problems of poor glass corrosion resistance, low physical and mechanical strength, weak corrosion resistance, etc., to achieve the effect of fast processing speed, saving rework, and eliminating the generation of micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

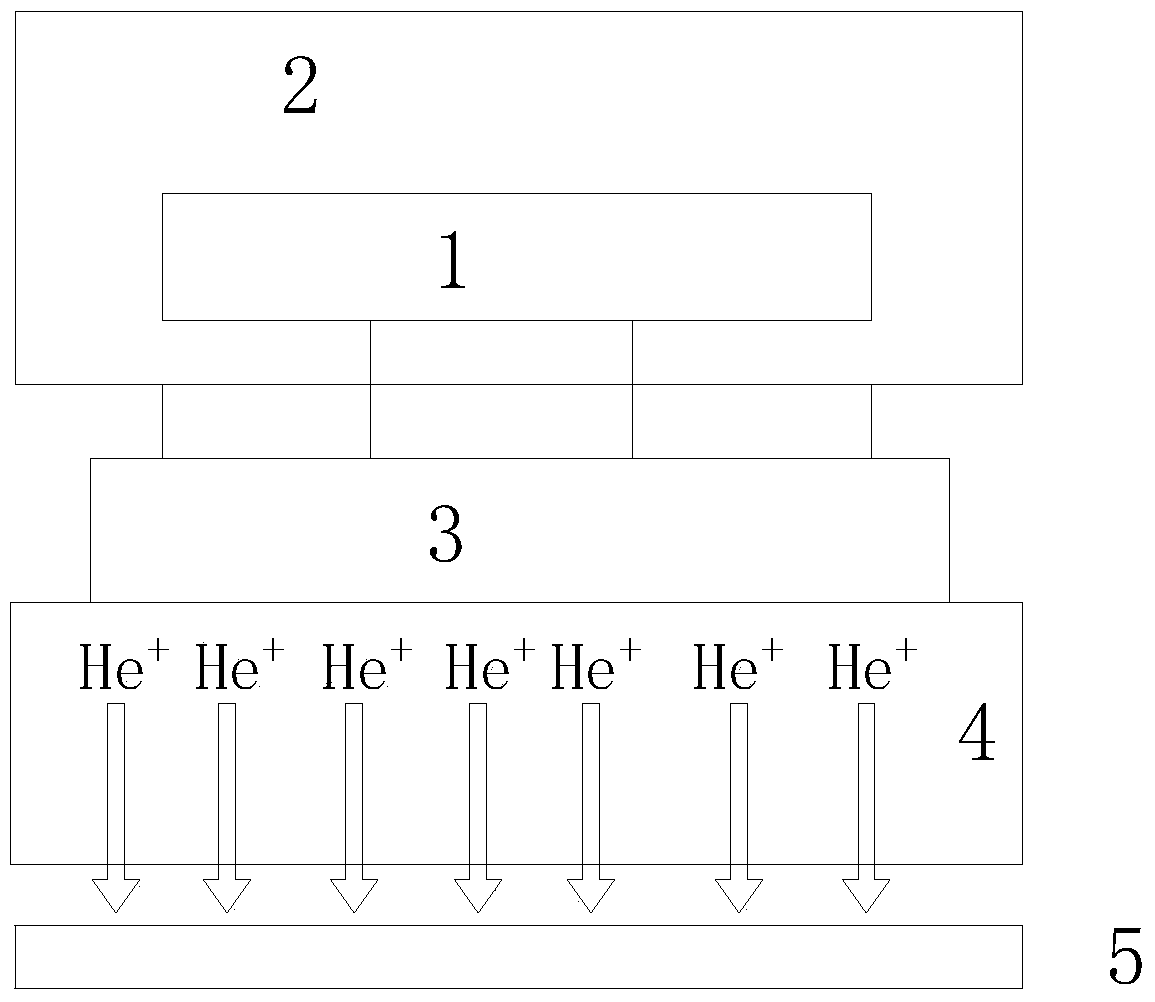

[0018] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0019] A kind of preparation method of sapphire-glass laminate, it comprises the following steps:

[0020] (1) Inject He on the surface of sapphire material + Ion layer: He will have kinetic energy and momentum + Ions are implanted into the surface of the chemically mechanically polished sapphire material at a uniform velocity, making the He + Ions accumulate on the surface of the sapphire material to form He + ion layer;

[0021] (2), strip He + Ion layer: He will be implanted + The ionic sapphire material is put into the annealing furnace and filled with inert gas, and then undergoes rapid annealing. The annealing temperature is 350°C-500°C, and the annealing time is 20 ~ 40 seconds until He + Ions overflow from the accumulation layer in the form of gas, and at least one side i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com