Calibration device for PM2.5 sensors and calibrating method thereof

A sensor and standard sensor technology, used in scientific instruments, measuring devices, suspension and porous material analysis, etc., can solve the problems of large rework, waste in production and after-sales, and low accuracy, so as to ensure measurement accuracy and reduce production. cost, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

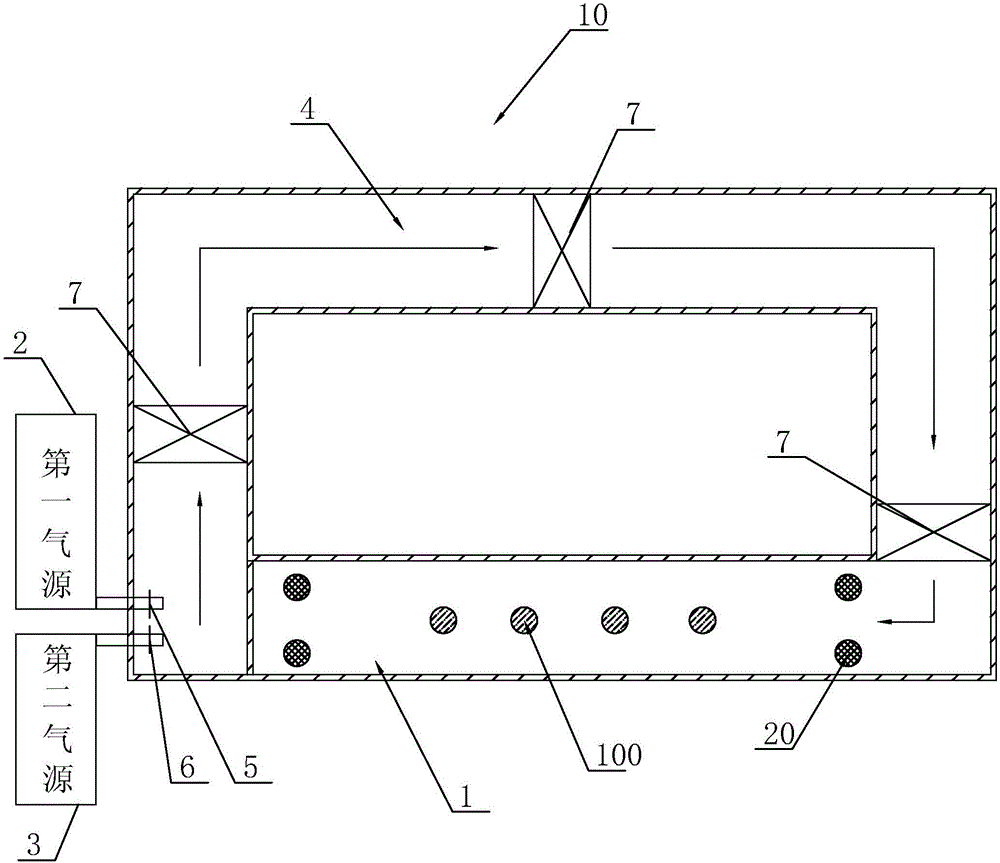

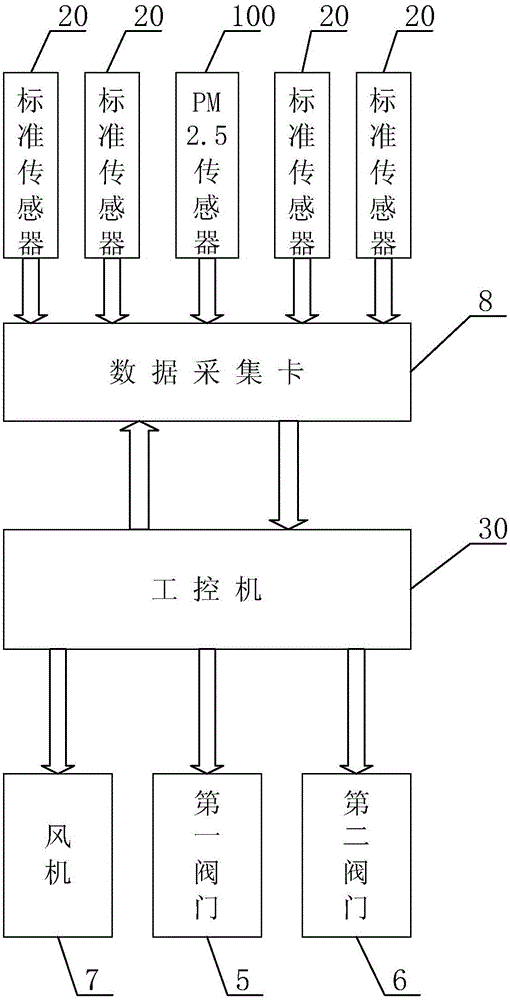

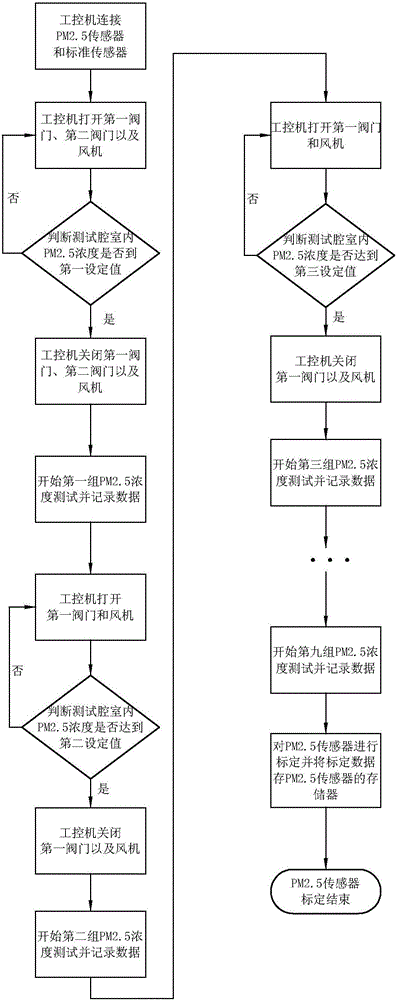

[0028] Such as Figure 1 to Figure 3 As shown, a PM2.5 sensor calibration device according to the present invention is used for the detection and calibration of the PM2.5 sensor 100 . The PM2.5 sensor calibration equipment includes a PM2.5 gas generator 10 , a standard sensor 20 and an industrial computer 30 . The PM2.5 gas generating device 10 includes a test chamber 1 containing a mixed gas, a first gas source 2 , a second gas source 3 and a gas mixing delivery channel 4 . Both the first air source 2 and the second air source 3 can output air, and the air output by only one air source contains PM2.5 particles. In this embodiment, the air output from the first air source 2 is filtered clean air without PM2.5 particles, and the air output from the second air source 3 contains PM2.5 particles. The first gas source 2 and the second gas source 3 communicate with the test chamber 1 through the gas mixing delivery channel 4, the air output from the first gas source 2 and the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com