Modular retaining wall

a technology of retaining walls and modules, applied in the direction of walls, piers, groynes, etc., can solve the problems of less than effective seawalls, requiring replacement and repairs, and erosion of land, and achieve the effects of reducing maintenance costs, improving strength, and speeding up installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention is described with reference to the accompanying figures, which illustrate the best mode known to the inventor at the time of the filing of the application illustrating the modular retaining wall of the invention.

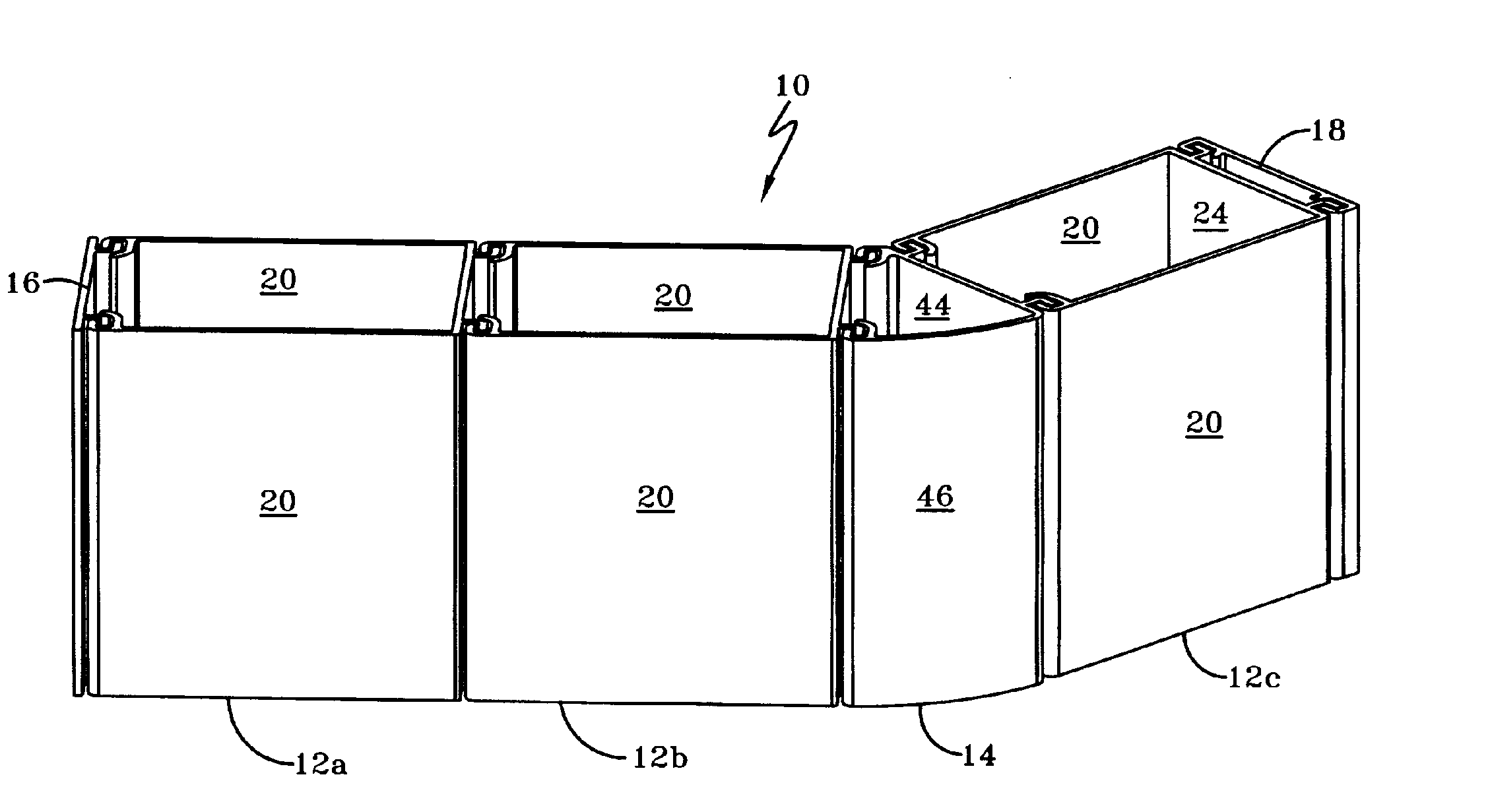

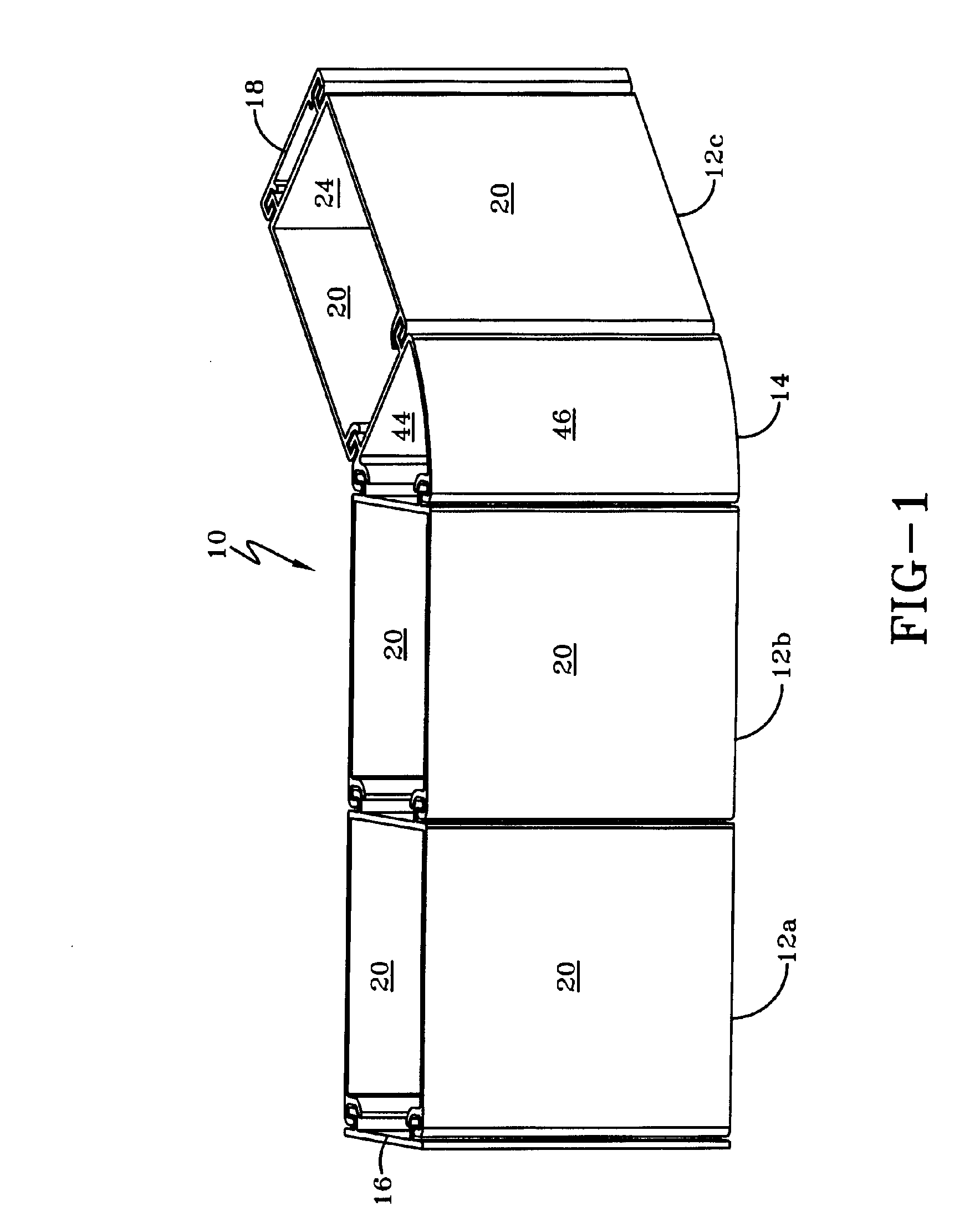

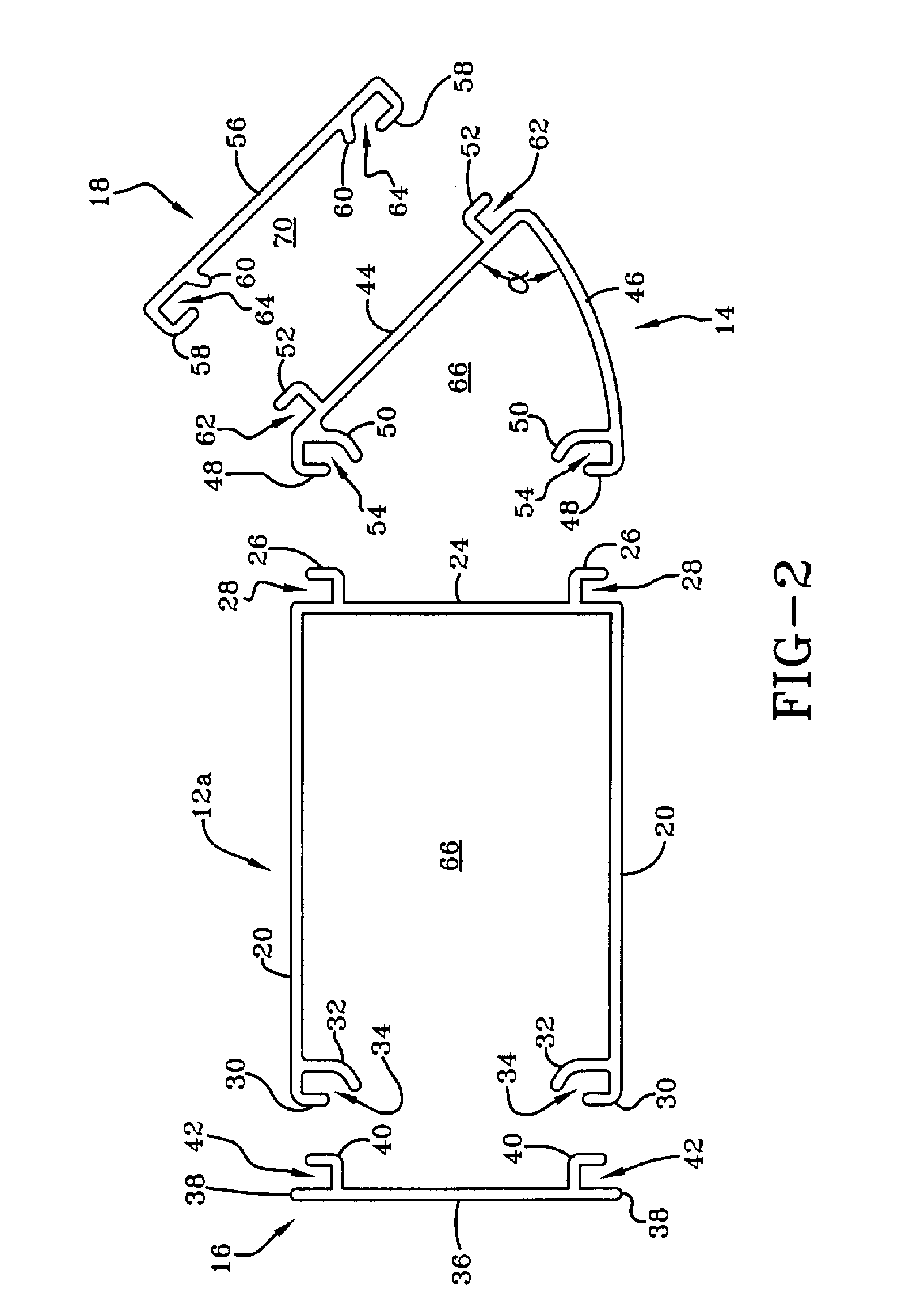

[0031] As better illustrated in FIG. 1, retaining wall 10 consists of various modules which form a contiguous barrier wall across a length of the modules when in their assembled state. Some modules are essentially interlocking linear U-shaped channels, e.g., 12a, 12b, and 12c whereas other interlocking modules, e.g., angled module 14, are used to impart non-linearity to the wall. As illustrated in the figure, the imparted angle is approximately 45°, although this is but an example of any angle between 1° and 180°, the end-use application, which in an aqueous environment will be the shoreline defining the requisite angularity required for the non-linear modules. The combination of linear U-shaped modules with non-linear modules provides essentially limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com