Method for evaluating material reheating crack sensitivity through stress relaxation test

A technology of stress relaxation and reheat cracking, applied in the direction of applying stable tension/pressure to test the strength of materials, analyzing materials, strength characteristics, etc., can solve the problems of long test period, low precision, large data error, etc., and achieve test The effect of short cycle time, less material consumption and less material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

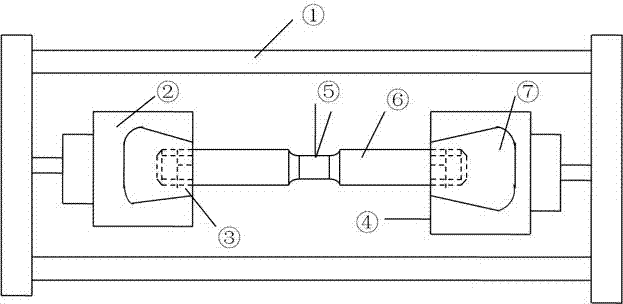

[0026] The stress relaxation test in this example is a method for evaluating the susceptibility of materials to reheat cracking. Complete the welding heat simulation and stress relaxation test directly in the Gleeble-3800 vacuum chamber, including the following steps:

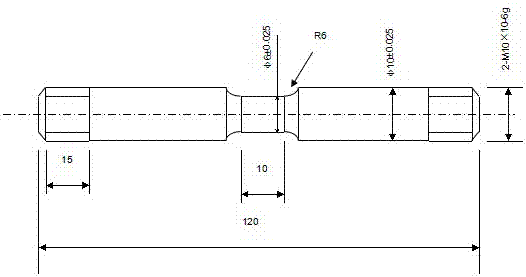

[0027] (1) Generally, samples are taken transversely from both sides at a distance of 1 / 4 thickness from the surface of the steel plate, and processed into such figure 1 As shown in the sample, the sample is in the shape of a long tube, both ends are processed to match the nut, and the middle is processed into a section of reduced diameter;

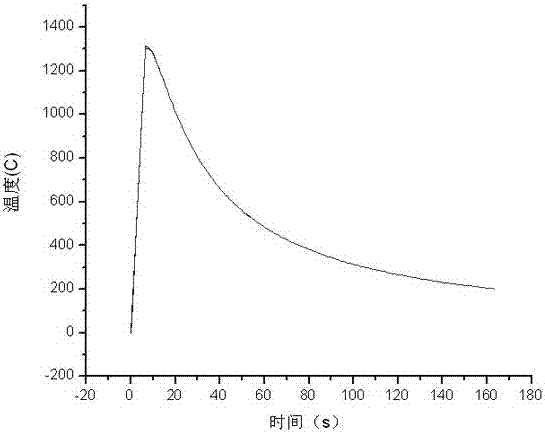

[0028] (2) Weld the thermocouple to the sample, and apply high-temperature cement to the spot welding part of the thermocouple to prevent the thermocouple from falling off. When the heating temperature of the sample does not exceed 1200°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com