Method for analyzing validity of degradation data on basis of failure physics

A technology of failure physics and degradation data, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of erroneous reliability data, unable to represent the true life of the test piece, work troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

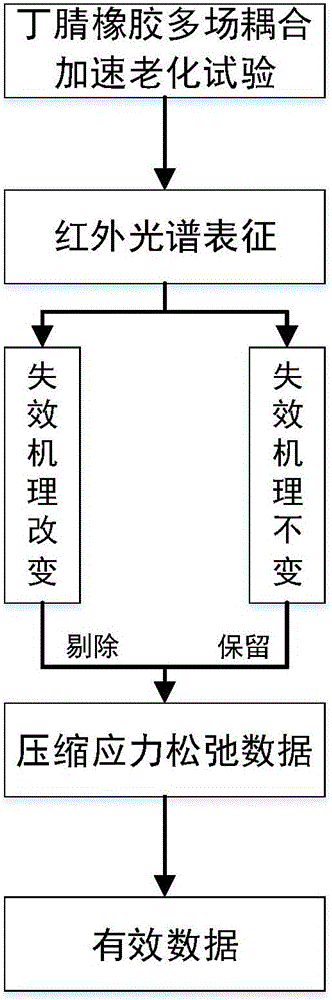

[0039] For the validity analysis method of degradation data based on failure physics involved in this embodiment, see figure 1 shown. The present invention is a method for analyzing the validity of degradation data based on failure physics, and its specific implementation steps are as follows:

[0040] Step 1. Accelerated thermo-oxidative aging test of nitrile rubber

[0041] Step 1.1. According to the main influencing factors of the failure of the nitrile rubber seal, it is determined to be a constant stress accelerated test, and temperature is selected as the accelerated stress.

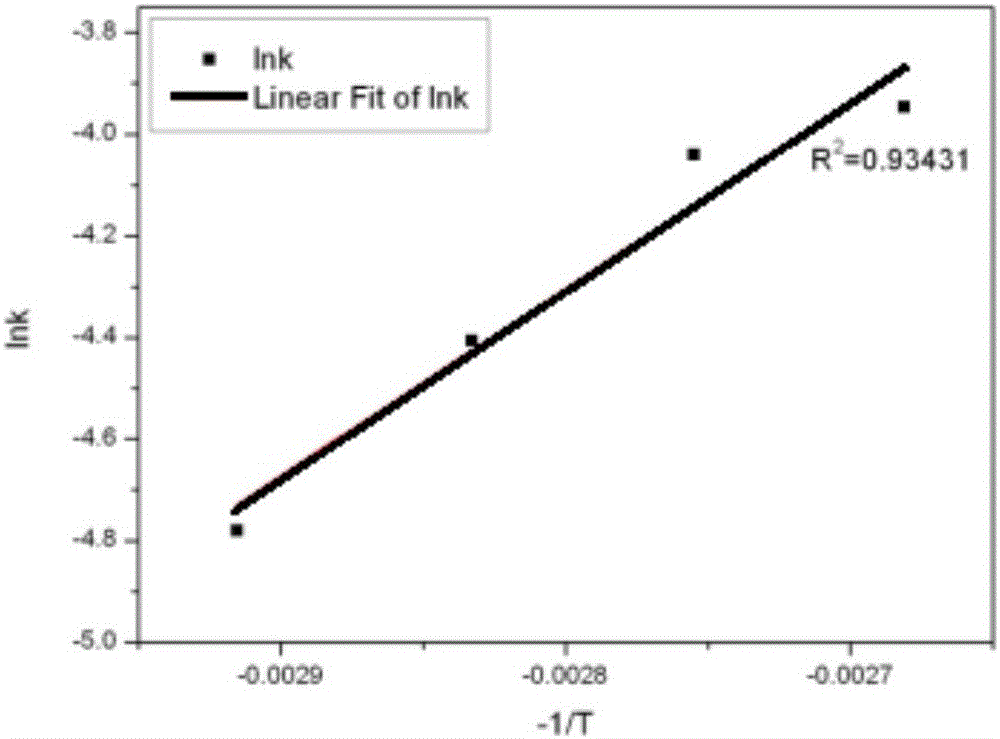

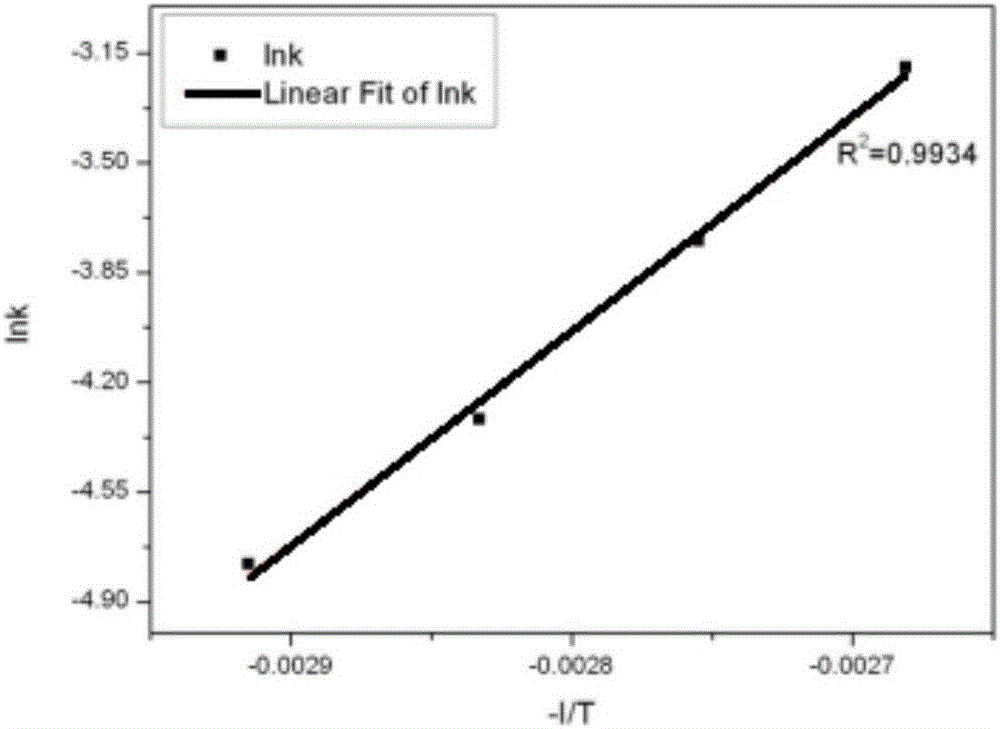

[0042] Step 1.2. Select temperature as the accelerated stress. Referring to the national standard GB / T2941-2006, determine the three levels of temperature stress as 70°C, 80°C, 90°C and 100°C.

[0043] Step 1.3, refer to the national standard GB1685-1982 "Determination of Compressive Stress Relaxation of Vulcanized Rubber at Room Temperature and High Temperature" to test the compressive stress, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com