Double-sided pressure-sensitive adhesive sheet and pressure-sensitive adhesive type optical member

A pressure-sensitive adhesive sheet, optical element technology, applied in optics, adhesives, adhesive types, etc., can solve problems such as uneven optical properties, improve foaming/peeling resistance, excellent stress relaxation properties, Anti-lifting and peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

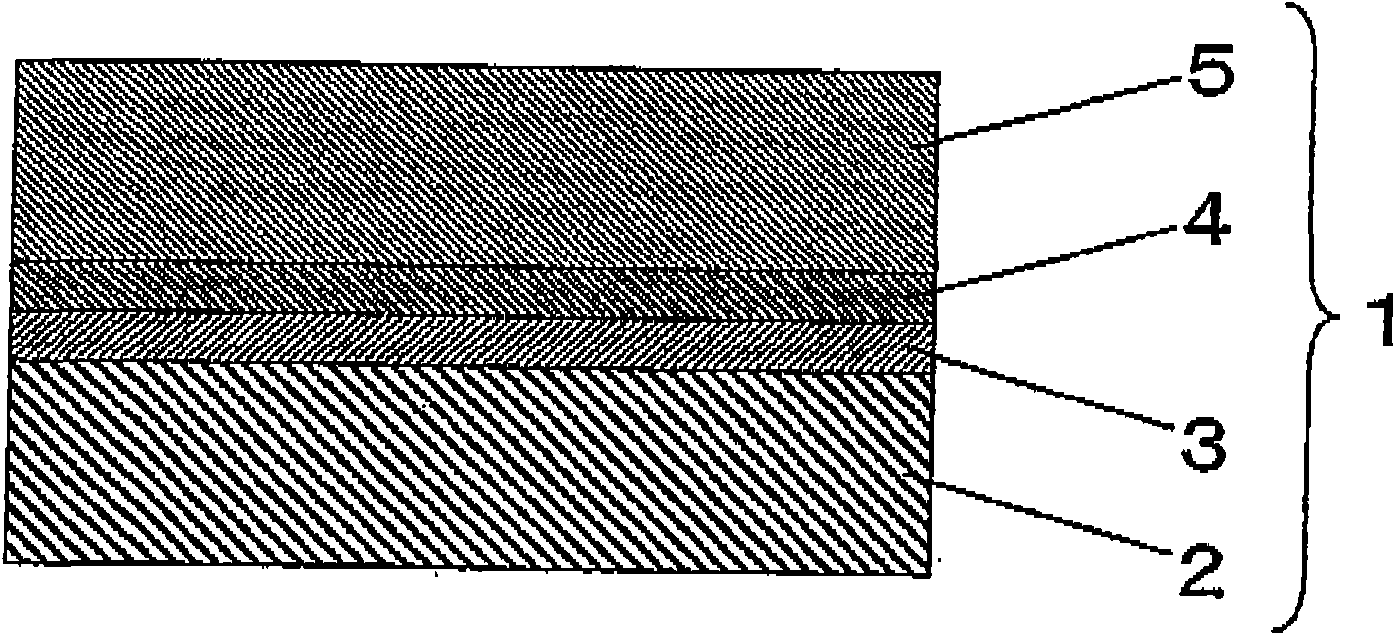

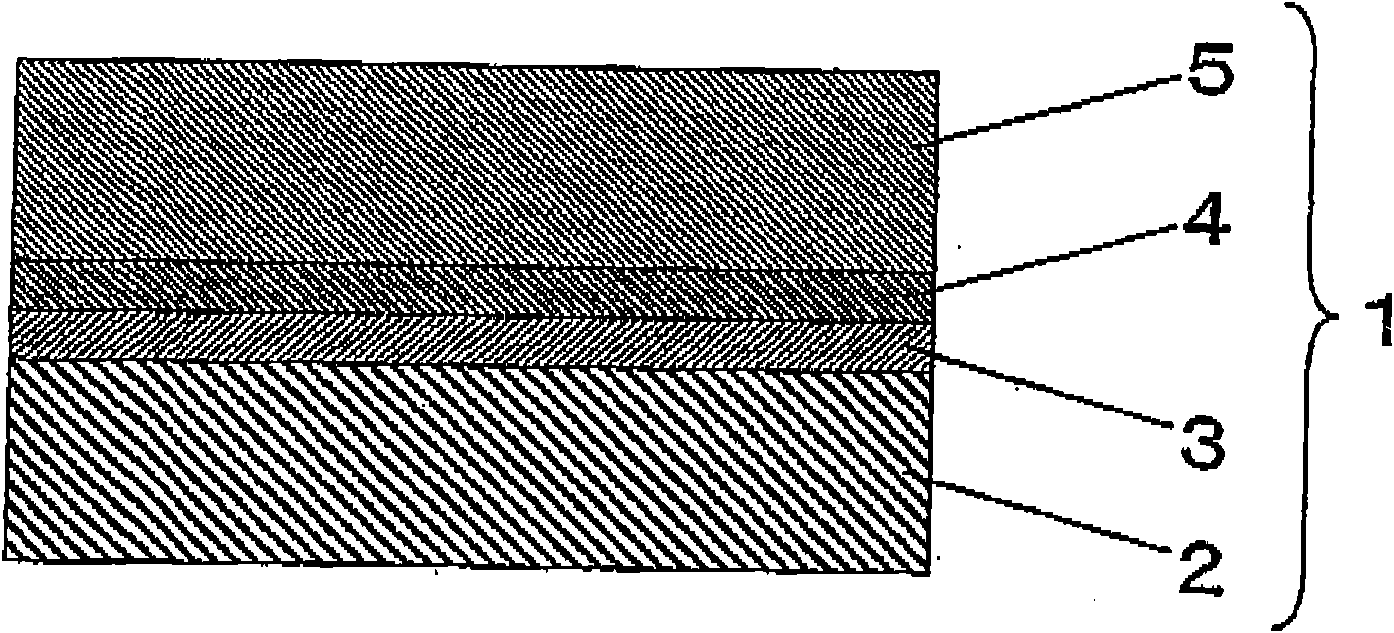

Image

Examples

Embodiment 1

[0100] By adding 69 parts by weight of 2-ethylhexyl acrylate (2EHA), 30 parts by weight of 2-methoxyethyl acrylate (2MEA), 1 part by weight of 4-hydroxybutyl acrylate (4HBA) and 1 part by weight 0.05 parts by weight of a product name "IRGACURE 184" manufactured by Ciba Chemicals and 0.05 parts by weight of a product name "IRGACURE 651" manufactured by Ciba Chemicals were blended into a mixture obtained by mixing acrylic acid (AA). Thereafter, ultraviolet rays were irradiated until the viscosity (BH viscometer, spindle No. 5, 10 rpm, measurement temperature 30° C.) reached about 20 Pa·s to prepare a prepolymer composition in which a part of the above-mentioned monomer components were polymerized.

[0101] To 100 parts by weight of the prepolymer composition, 0.01 parts by weight of trimethylolpropane triacrylate (TMPTA) was added to prepare a composition for forming an acrylic pressure-sensitive adhesive layer.

[0102] The composition for forming an acrylic pressure-sensitive ...

Embodiment 2 and 3

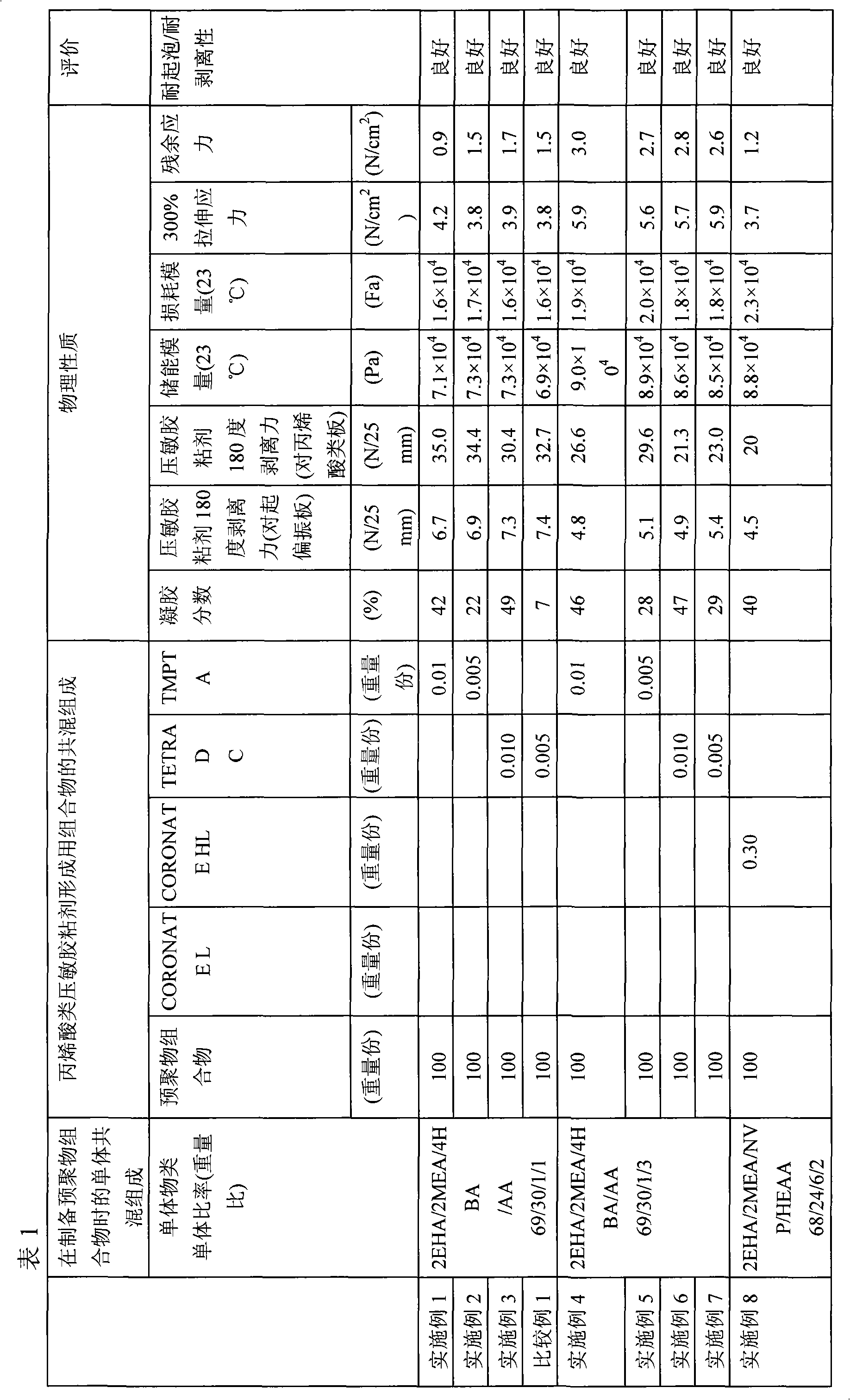

[0105] Examples 2 and 3, Comparative Example 1

[0106] A composition for forming an acrylic pressure-sensitive adhesive layer was prepared in the same manner as in Example 1, except that in Example 2 the amount of TMPTA added was changed, and in Example 3 and Comparative Example 1 no TMPTA and an epoxy crosslinking agent ("TETRADC", manufactured by Mitsubishi Gas Chemical Co., Ltd.) were added, as shown in Table 1.

[0107] Also, using the composition for forming an acrylic pressure-sensitive adhesive layer, a double-sided pressure-sensitive adhesive sheet (substrate-less double-sided pressure-sensitive adhesive sheet) was obtained in the same manner as in Example 1.

Embodiment 4~7

[0109] A prepolymer composition was prepared in the same manner as in Example 1 except that the ratio of acrylic acid (AA) was changed as shown in Table 1.

[0110] TMPTA or Tetrad C was added to the prepolymer composition obtained above as shown in Table 1 to prepare a composition for forming an acrylic pressure-sensitive adhesive layer.

[0111] Also, using the composition for forming an acrylic pressure-sensitive adhesive layer, a double-sided pressure-sensitive adhesive sheet (substrate-less double-sided pressure-sensitive adhesive sheet) was obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com