Numerical simulation method for thermal composite forming of titanium alloy

A numerical simulation, titanium alloy technology, applied in the field of material thermal processing, can solve problems such as the difficulty of creep relaxation research and the enhancement of numerical simulation dependence, and achieve the effect of low cost and accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Attached below Figure 1-11 The present invention is described in detail with specific examples.

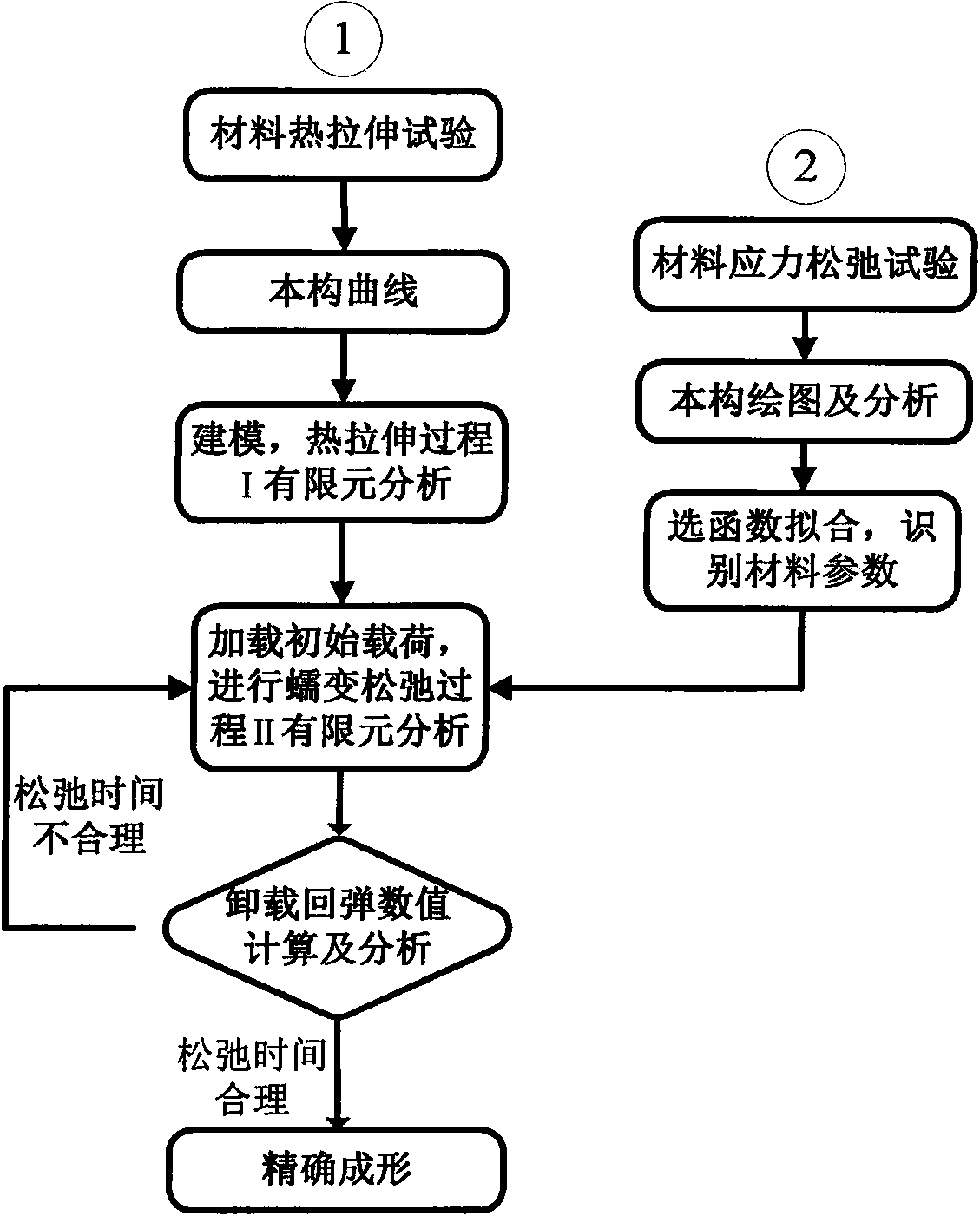

[0031] The invention provides a numerical simulation method for thermal compound forming of titanium alloy, the process of which is as follows figure 1 shown. The implementation of the present invention is divided into two stages: simulation of thermal stretching deformation process I and simulation of creep relaxation process II. The concrete steps of the invention are as follows:

[0032] (1) Numerical simulation of thermal tensile deformation process I

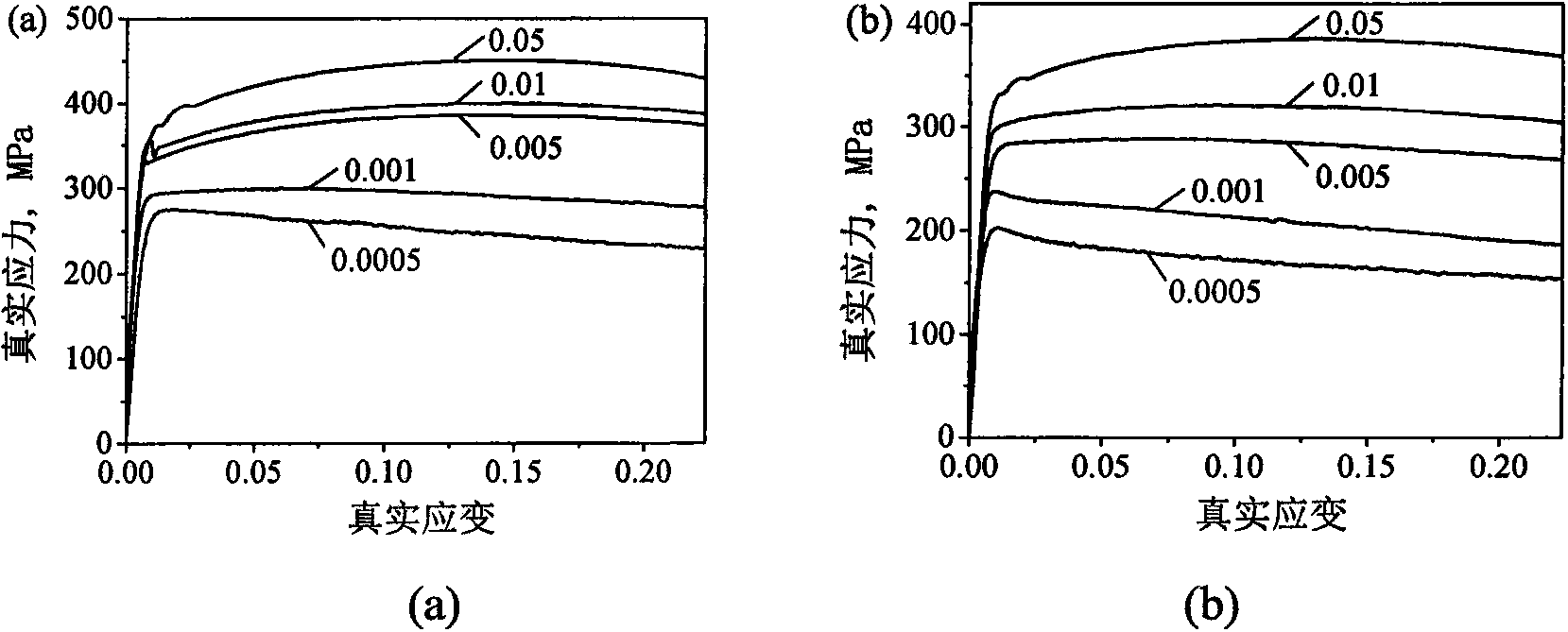

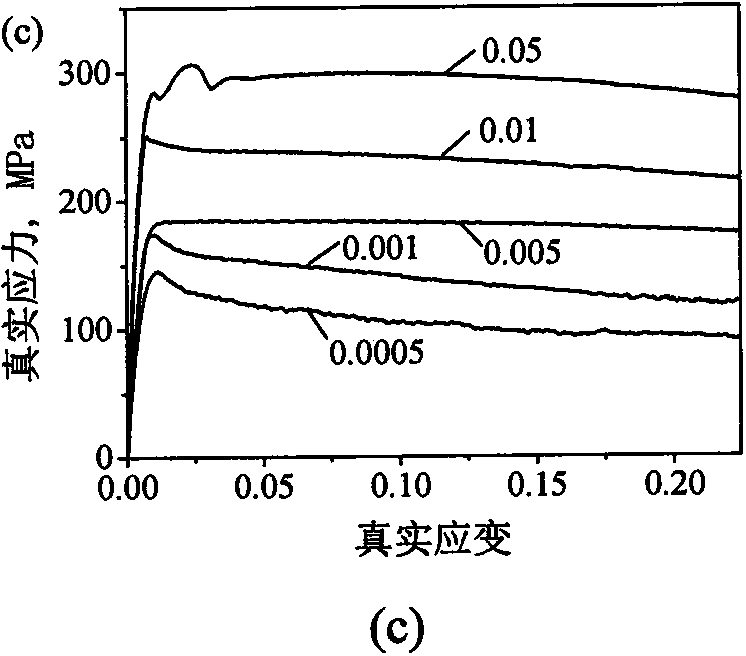

[0033] Step 1. Select TC4 titanium alloy material with a thickness of 1.5mm. Referring to the GB / T10120-1996 metal stress relaxation test method, the titanium alloy material is made into a round bar, plate or other shape sample. The tensile test was carried out on a material testing machine, and the tensile speed was controlled at 5mm / min. When the pre-stretching amount is 2%, the stress relaxation test is carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com