Testing method for normal temperature and high temperature stress relaxation of flat spring

A stress relaxation, leaf spring technology, applied in the field of normal temperature and high temperature leaf spring stress relaxation test, can solve the problems of low degree of automation, complex measurement, large error, etc., to improve work efficiency, simple operation, and avoid errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

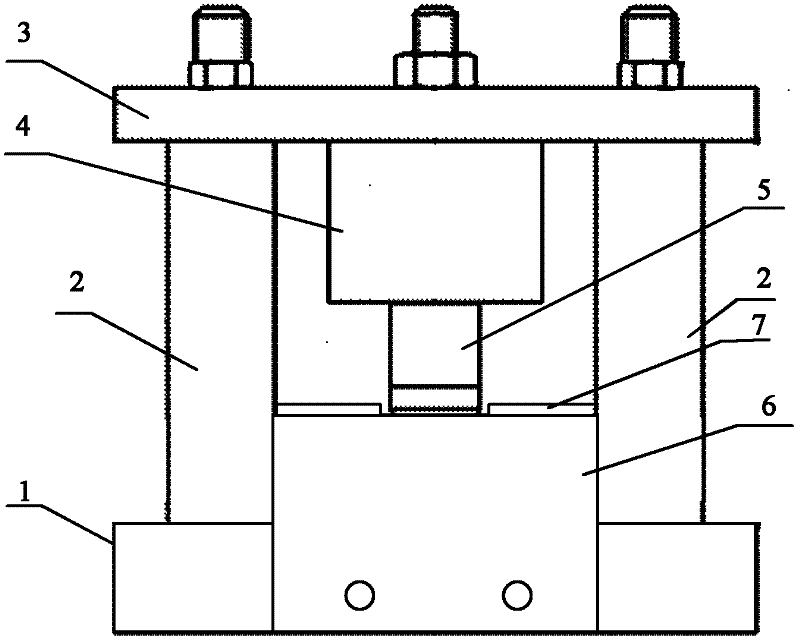

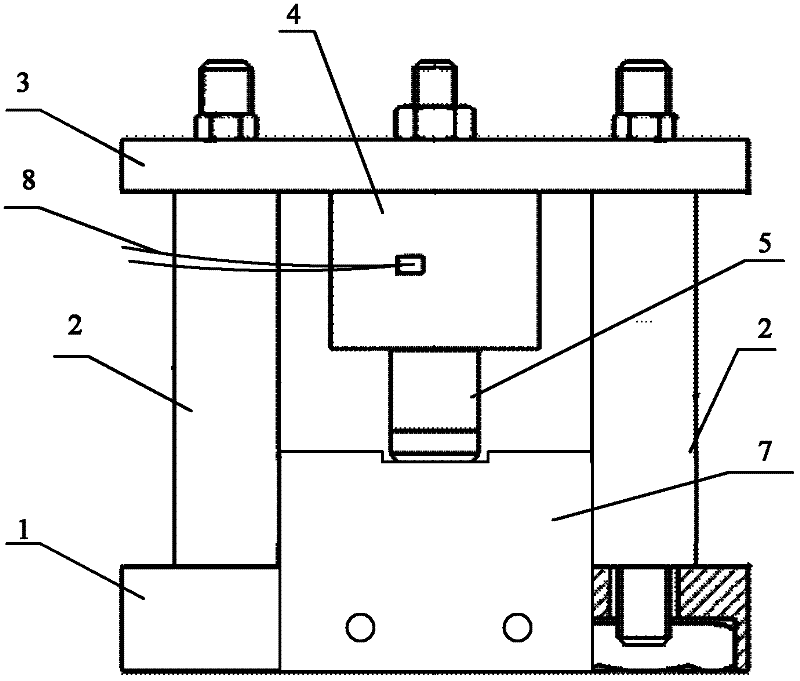

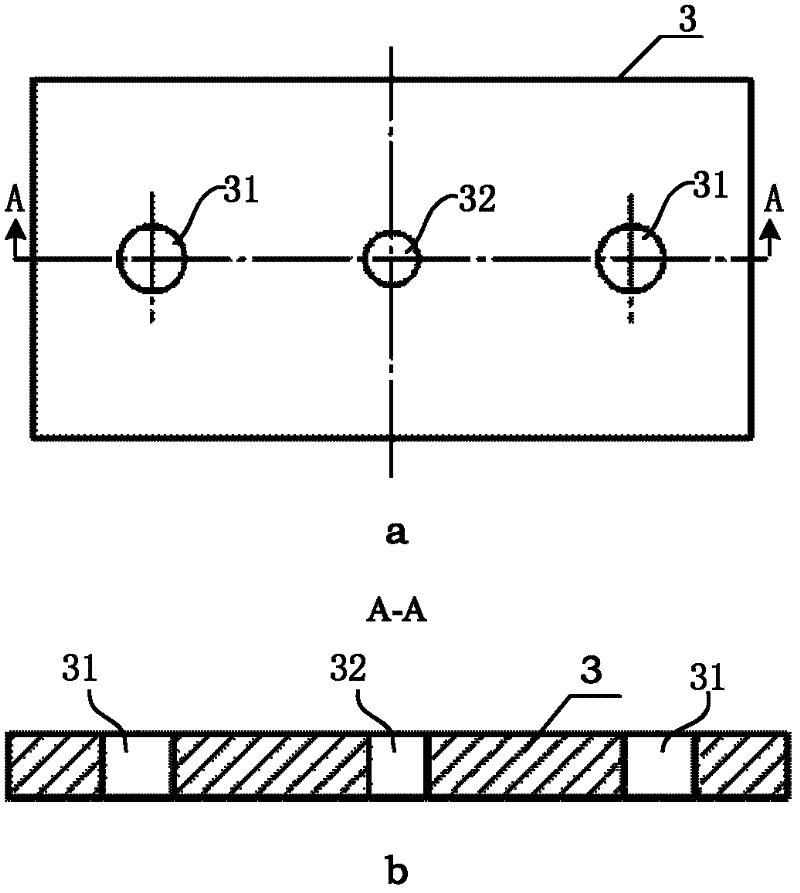

[0036] The test mode provided by the present invention is based on the following test equipment, such as figure 1 and image 3 As shown, the test equipment mainly includes the following modules: a base 1 , a limiter 2 , an upper plate 3 , a pressure sensor 4 , an indenter 5 , a front side plate 6 and a rear side plate 7 .

[0037] Such as figure 1 and 2 As shown, the upper board 3 is placed directly above the base 1 , and the base 1 corresponds to the center of the upper board 3 . The base 1 and the upper plate 3 are fixed together by two limiters 2 on the left and right. A pressure sensor 4 is fixed at the center of one side of the upper plate 3 opposite to the base 1 , and an indenter 5 is fixed at the other end of the pressure sensor 4 . The pressure sensor 4 is connected with the external data display instrument by the sensor lead wire 8, and the pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com