Reliability determination method based on compression spring stress relaxation testing data

A technology of stress relaxation and test data, which is applied in the field of reliability determination based on compression spring stress relaxation test data, which can solve problems such as long test time, poor accuracy of evaluation data sources, and large data dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0073] Such as Figure 6 As shown, a reliability determination method based on compression spring stress relaxation test data, including Figure 6 The steps shown in the following are illustrated by an example.

[0074] 1. Installation and test preparation of test equipment

[0075] In this example, a helical compression spring wound with 60Si2MnA oil-quenched and tempered steel wire is used for the test. The basic parameters of the spring are d=2mm, D=15mm, t=10mm, H 0 = 65mm.

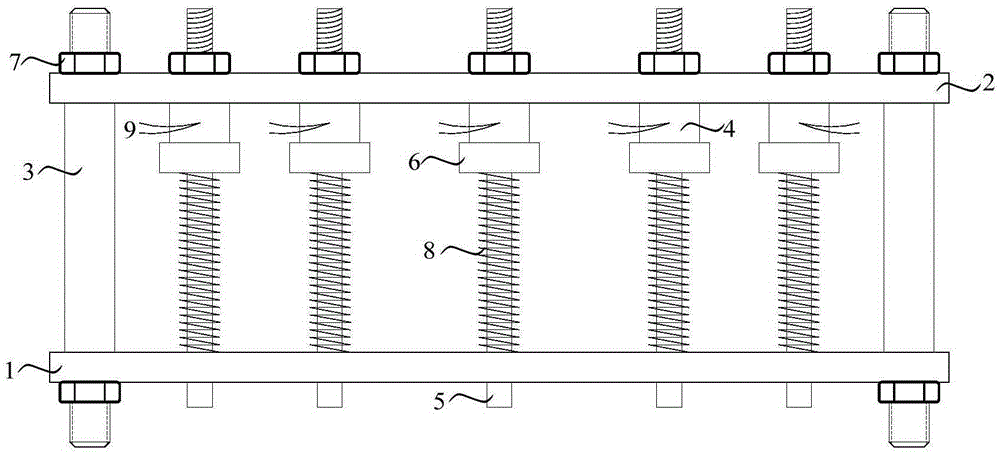

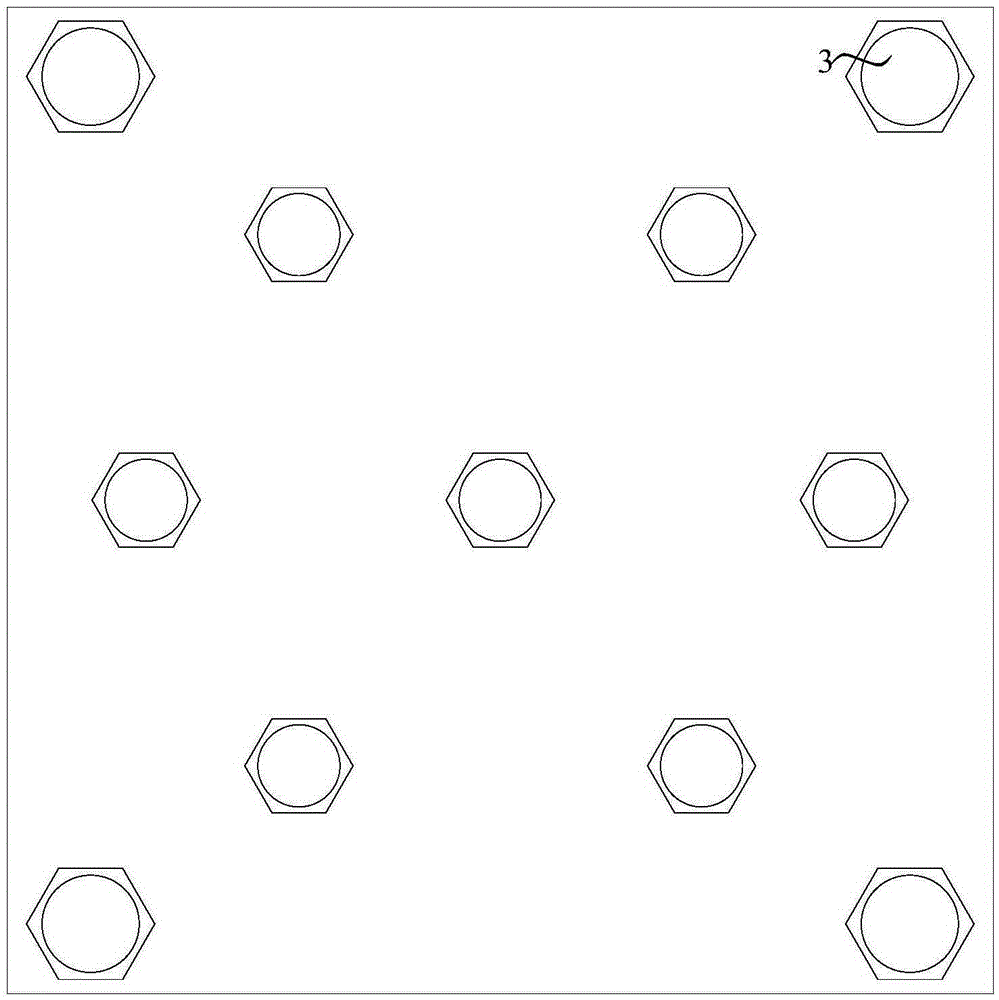

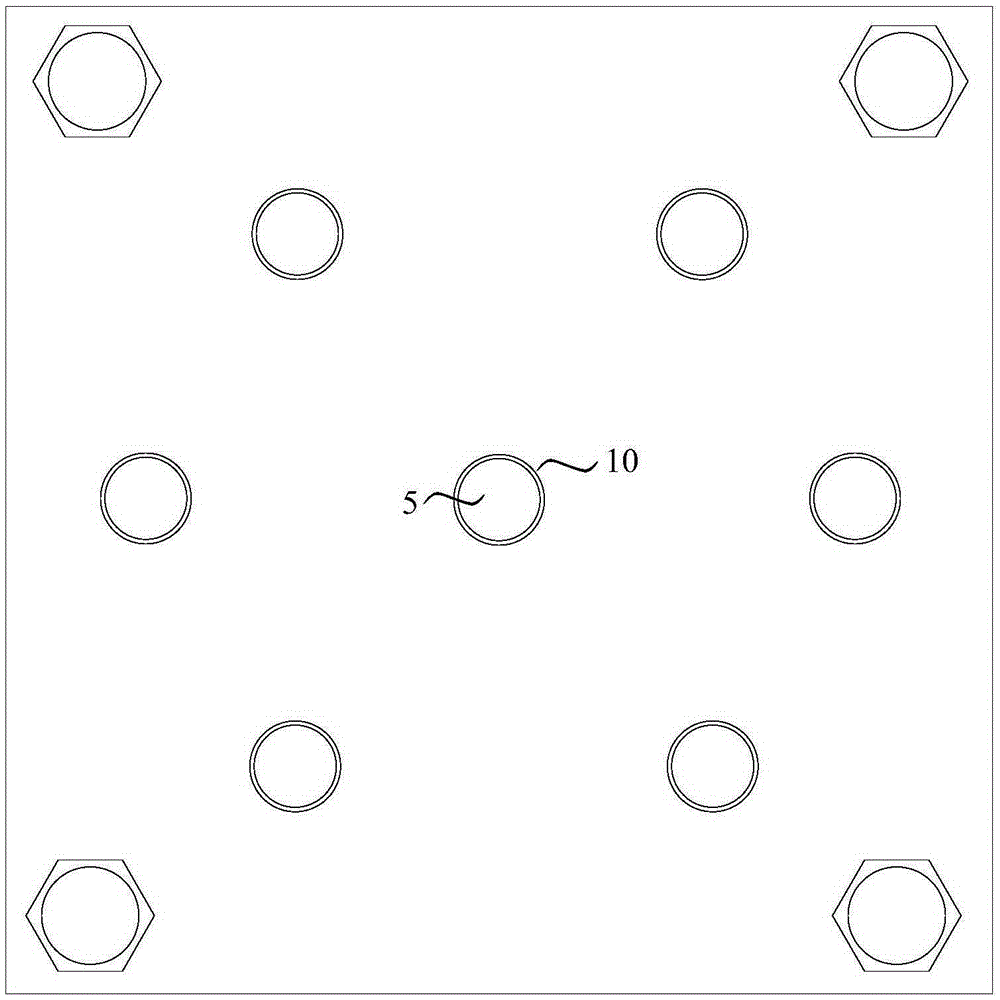

[0076] The present invention provides a kind of stress relaxation test equipment that can be used for the reliability assessment of compression springs, such as figure 1 and figure 2 As shown, it mainly includes the following modules: bottom plate 1, top plate 2, mounting screw 3, pressure sensor 4, push rod 5, push rod cap 6 and loading nut 7.

[0077] Such as figure 1 and figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com