Specimen end clipping reinforcement method during FRP rib stress relaxation characteristics test

A technology for stress relaxation and anchor reinforcement, applied in strength characteristics, measuring devices, instruments, etc., can solve problems such as immature reinforcement methods, system errors, and difficulty in eliminating the effects of adhesive creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

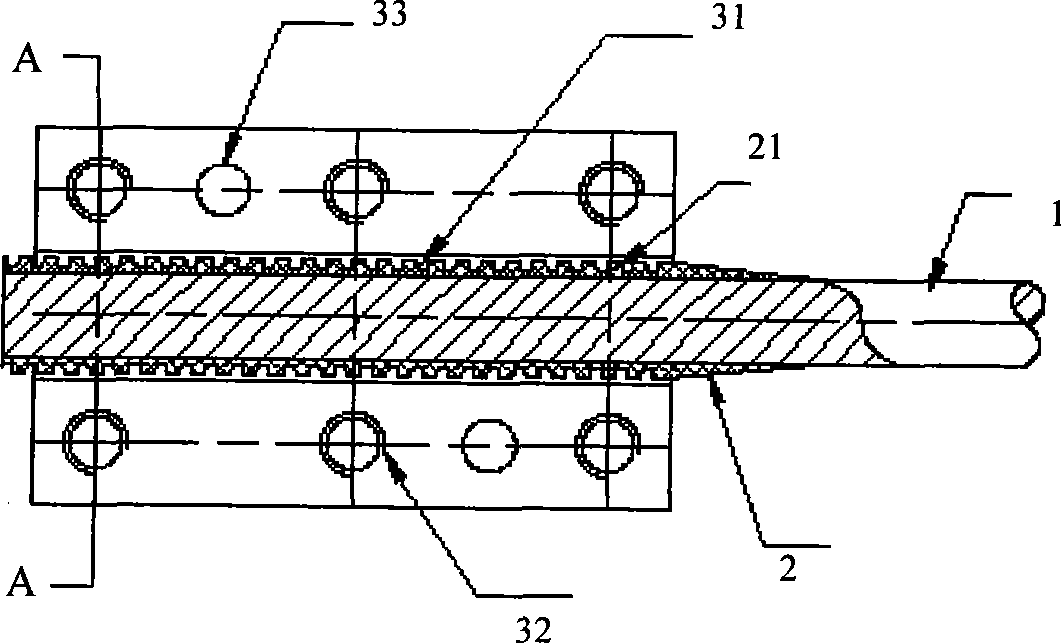

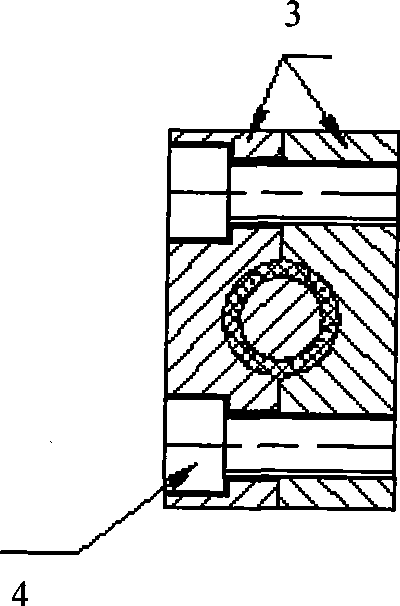

[0019] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0020] If the clip-type anchor is directly used at the end of the test piece, no matter whether the end of the test piece is reinforced by winding fiber cloth or a layer of soft metal in advance, the gap between the clip and the anchor cup cannot be avoided. The relative slip between the clip and the reinforcement at the clamping position makes the deformation of the test section unsteady, and the stress relaxation data tested based on this cannot truly reflect the stress relaxation characteristics of the FRP reinforcement, and because the FRP reinforcement is resistant to collapse The pressure capacity is poor, and it is easy to cause extrusion damage at the anchor clip, which makes the test invalid; if the end uses a glued anchor, it usually needs a longer glued section, and the creep of the adhesive is large, which is bound to cause the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com