Testing method for creep relaxation of non-metal sealing gasket

A sealing gasket and creep relaxation technology, which is applied in the field of non-metallic sealing gasket testing, can solve the problems of difficult collection of effective data, many influencing factors, and low test efficiency, and achieve the effect of high test efficiency and simple test equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment. It should be understood that the "upper", "lower", "left", "right", "front" and "reverse" mentioned in the following embodiments of the present invention are all based on the directions shown in the figures, These words used to limit the direction are only for convenience of description, and do not mean to limit the specific technical solution of the present invention.

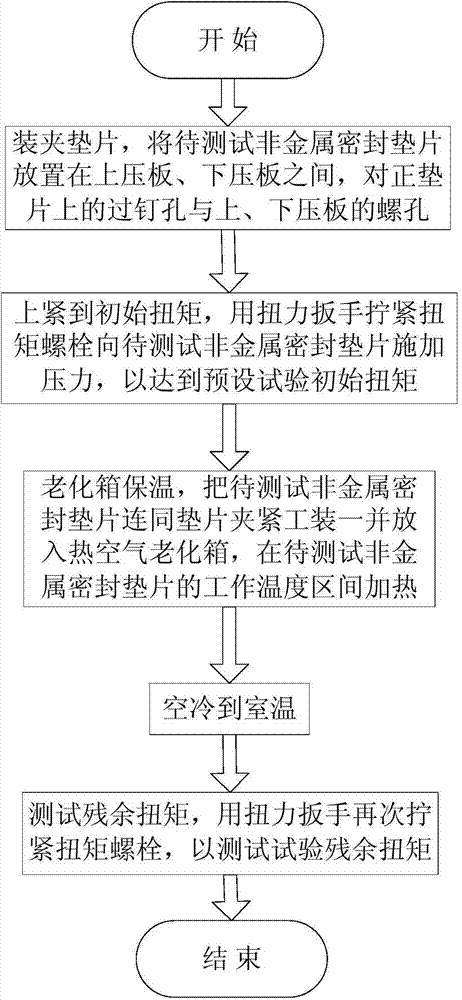

[0043] The non-metallic sealing gasket creep relaxation test method of the present invention evaluates the creep of the gasket by comparing the ability of similar products to maintain a given compressive stress over time under the same control conditions, that is, the degree of bolt torque loss relaxation rate. The test device is simple, and the finished ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com