Multifunctional material test clamp based on lever principle

A technology of material testing and lever principle, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of fixtures that are easy to rust, and achieve the effect of preventing the sample from slipping, the fixture structure is compact, and it is easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

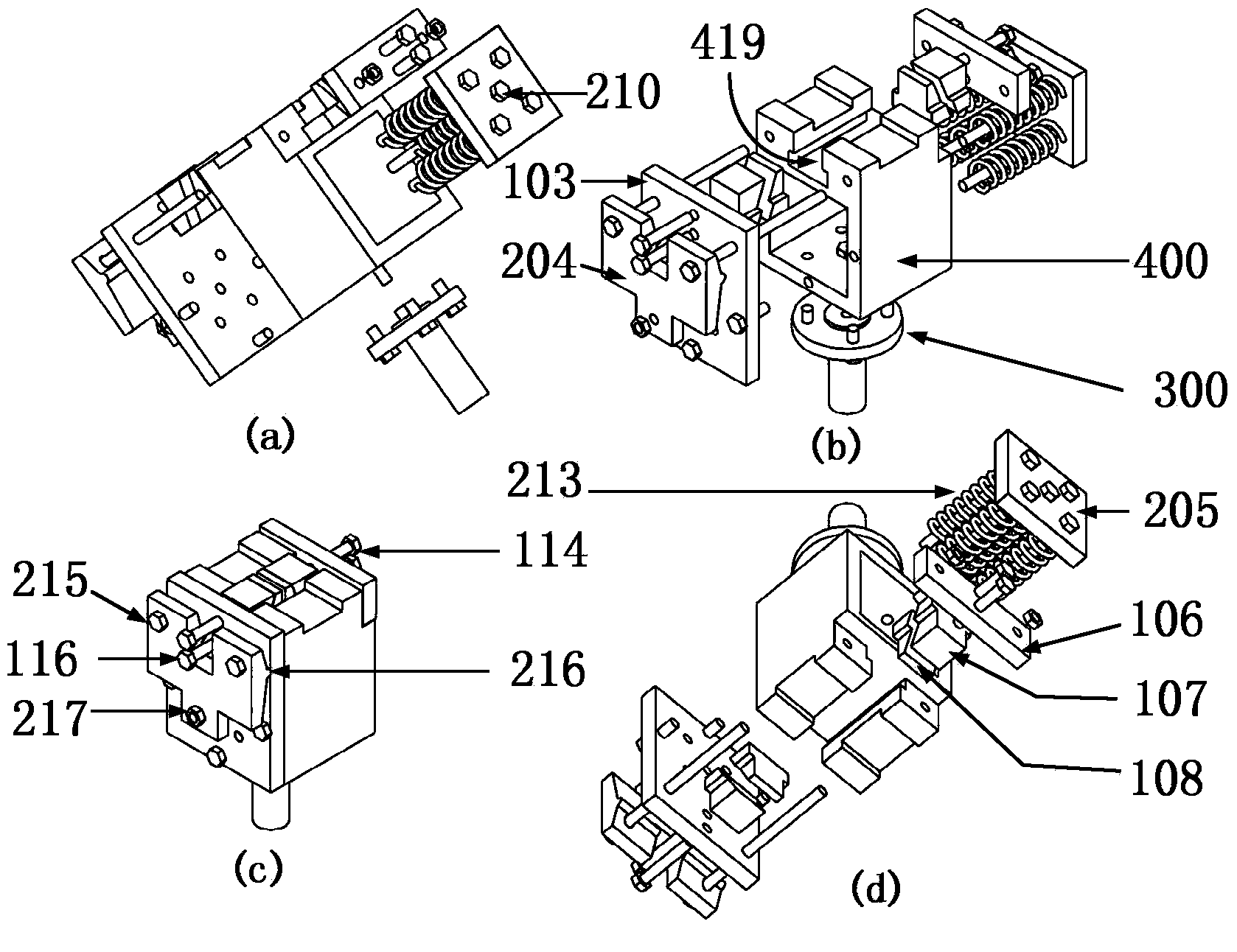

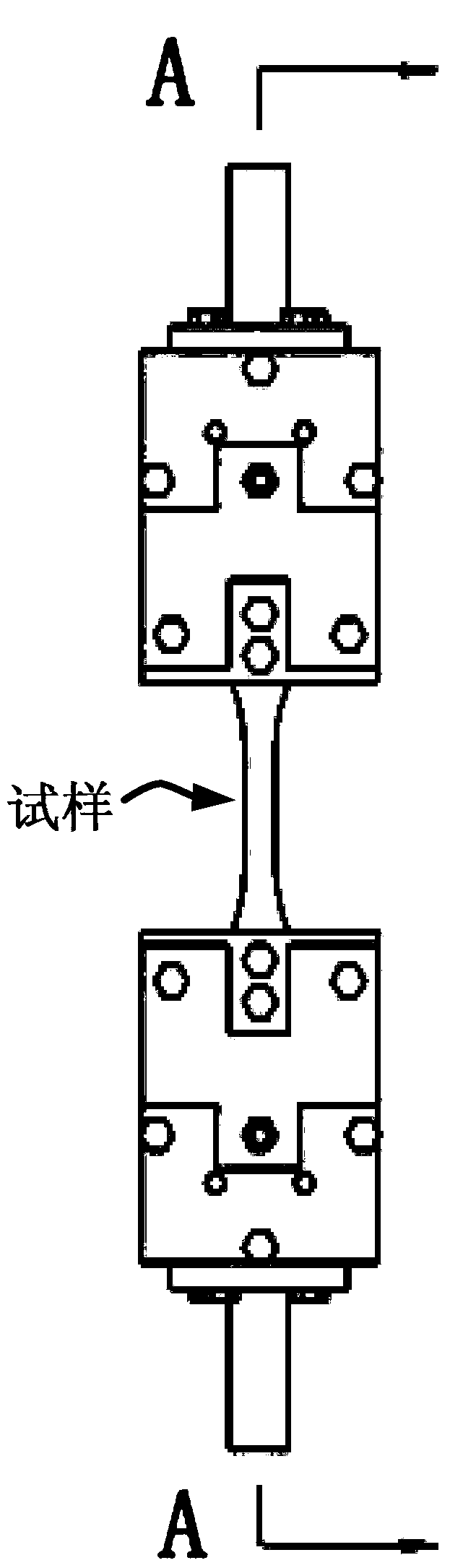

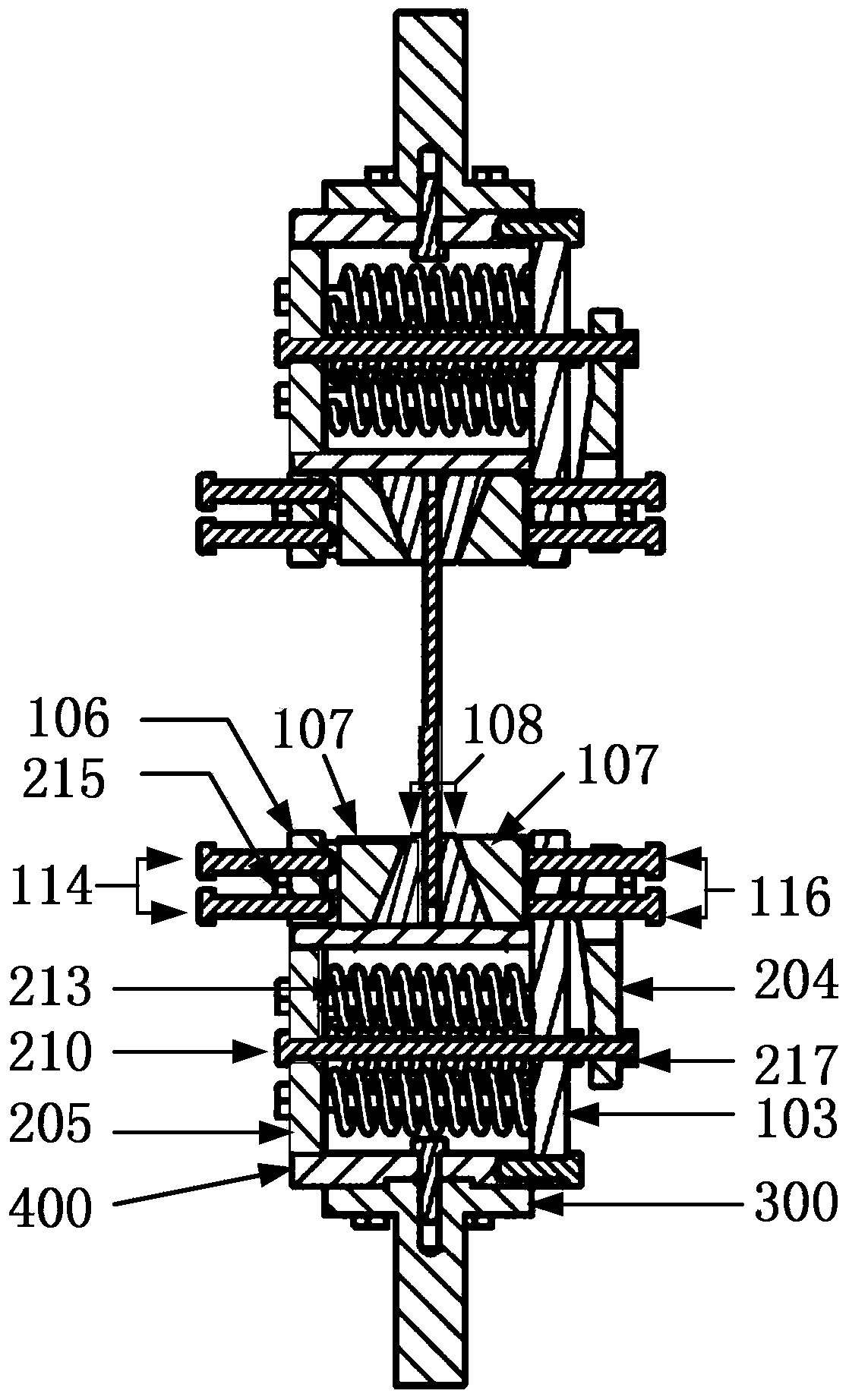

[0031] Such as image 3 As shown, a pair of fixtures of the present invention are used to clamp the sample and place it in an environmental chamber, and connect to the MTS material testing machine through an adapter flange 300 . When loading the sample, first adjust the centering bolt 116 according to the thickness of the sample so that the center of the sample coincides with the center of the fixture, then lightly tighten the pre-tightening bolt 114 to make the clamp close to the sample, and finally tighten the compression nut with a wrench 217 to obtain a suitable clamping force. After the test is finished, loosen the booster nut 217 with a wrench to loosen the clamp and take out the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com