Patents

Literature

36results about How to "Appropriate clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clamp

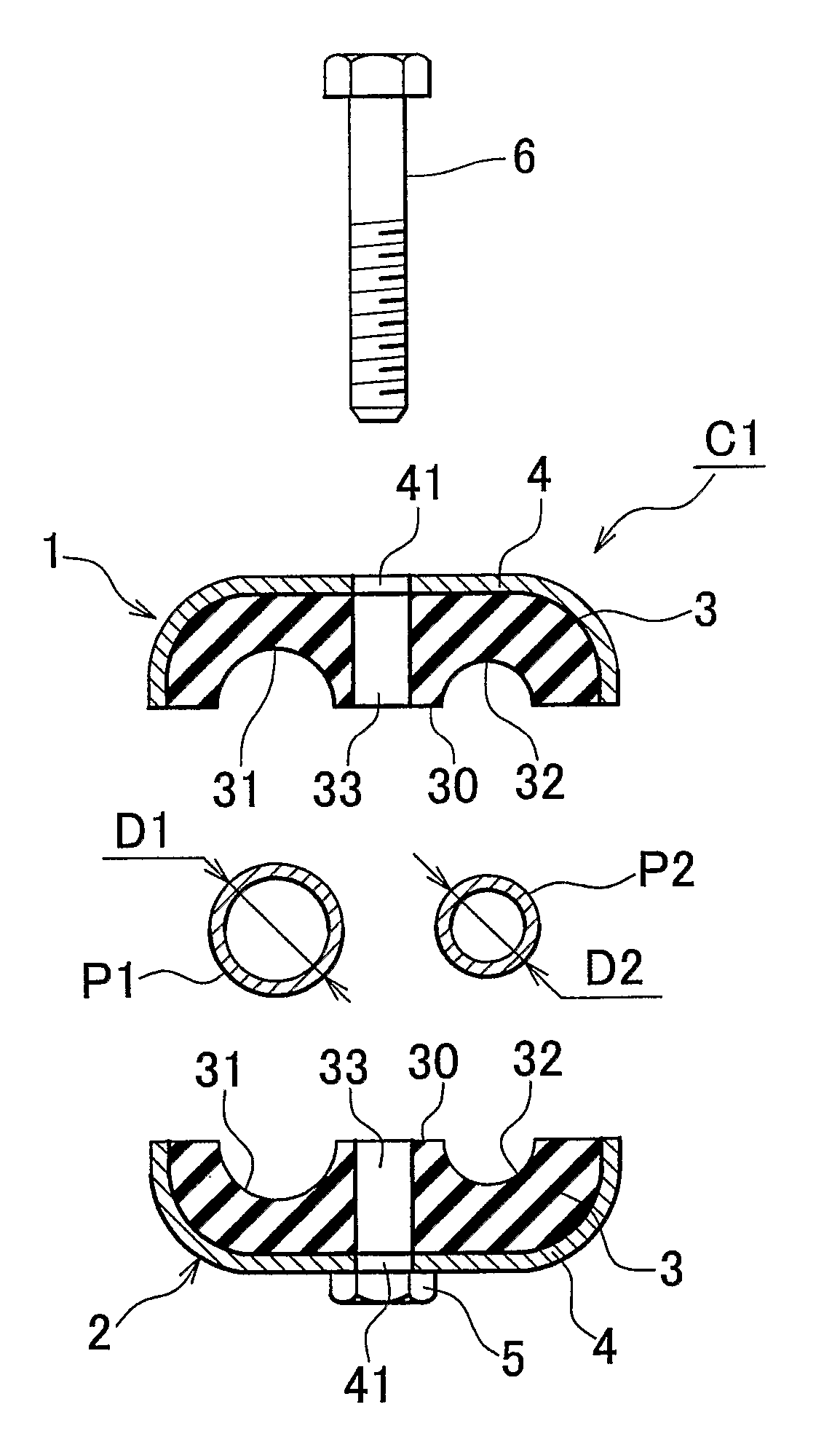

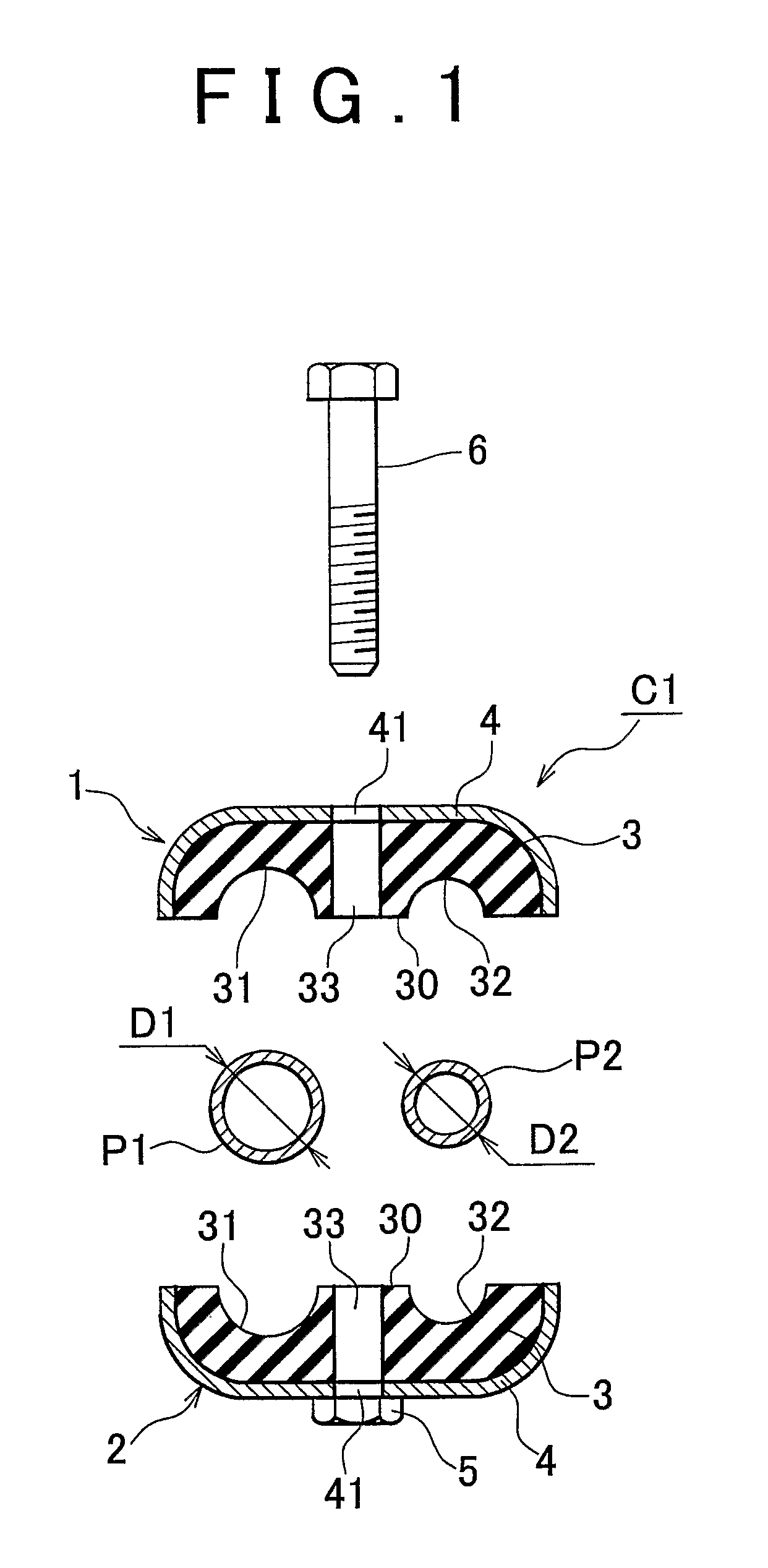

InactiveUS7530536B2No fear of the pipes deformingGood vibration absorptionPipe supportsRacksElastomerEngineering

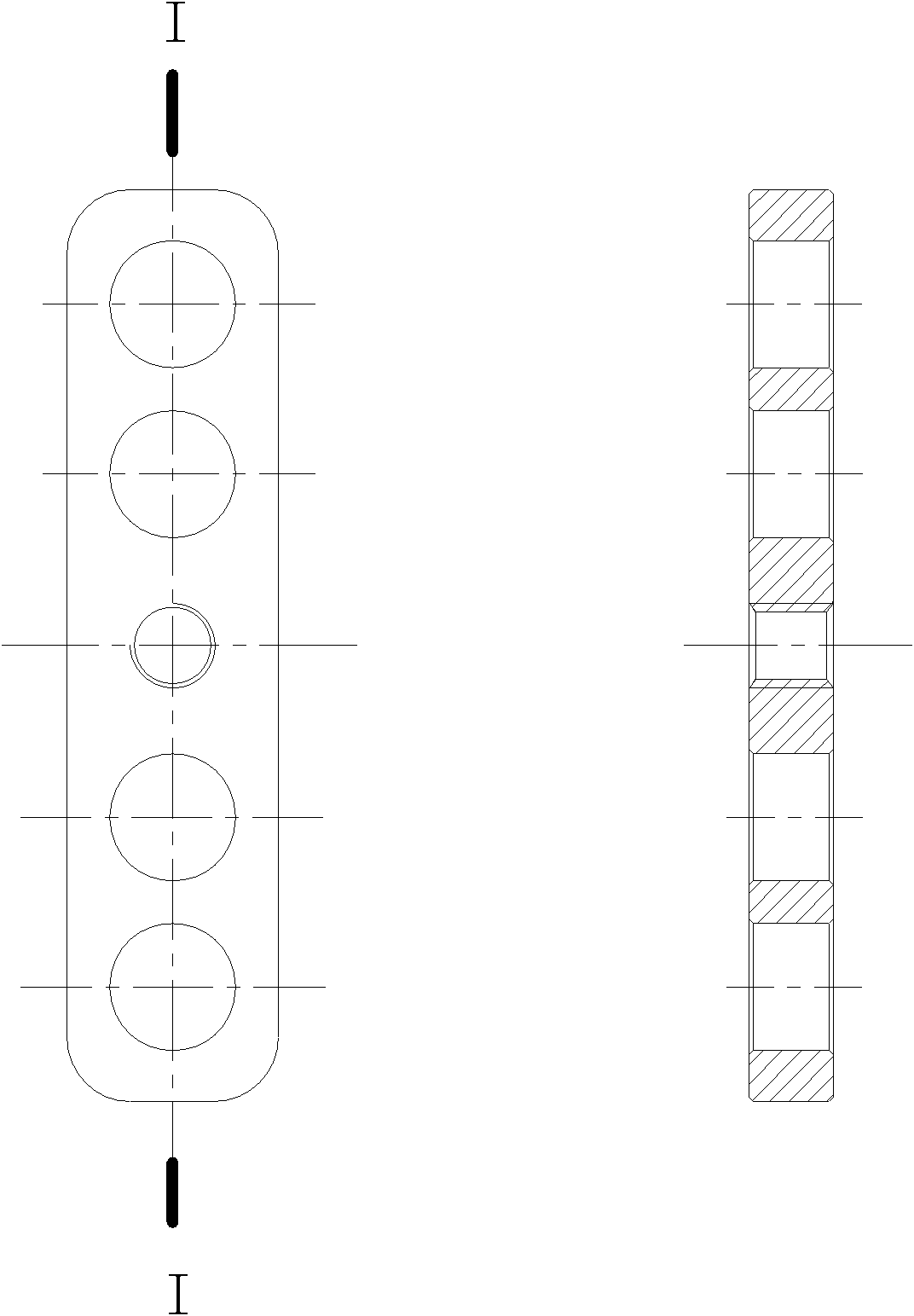

In a clamp having a pair of clamp members which sandwich a plurality of pipes having cylindrical cross-sections of different diameters, each of the clamp members including an elastic body having a plurality of concave portions formed therein and a reinforcing plate fixed to an outer side surface of the elastic body, the dimensions of each portion of the elastic bodies are set such that the compression ratio of the elastic bodies with respect to all of the pipes is made the same. For example, when the diameters of two pipes having different outer diameters are made D1 and D2, the curvature radii of the concave portions of the elastic bodies are made R1 and R2, and the distances from mating faces of the elastic bodies to the reinforcing plates are made L11, . . . , L22, then the dimensions of each portion of the elastic bodies are set so as to satisfy the relationship [(D1−2R1) / (L11+L12−2R1)=(D2−2R2) / (L21+L22−2R2).

Owner:TOYOTA JIDOSHA KK

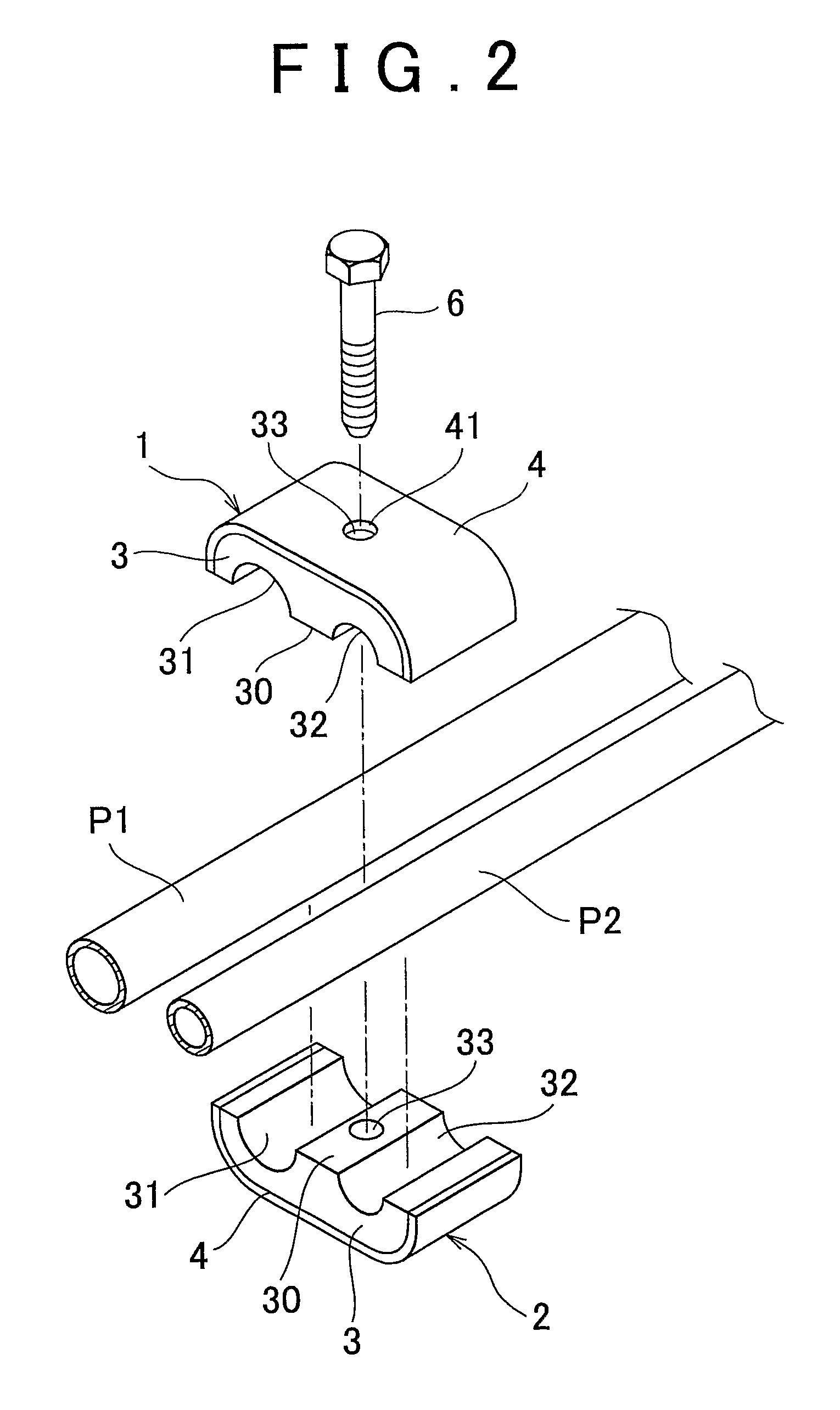

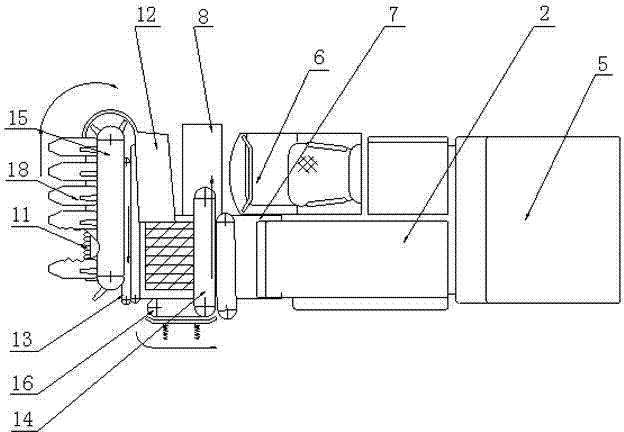

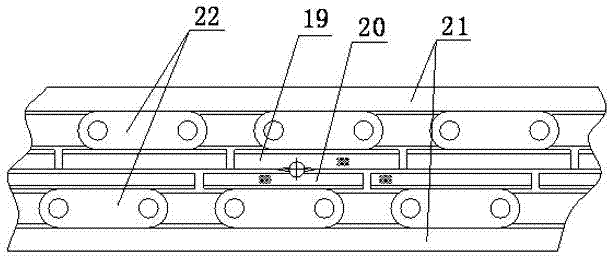

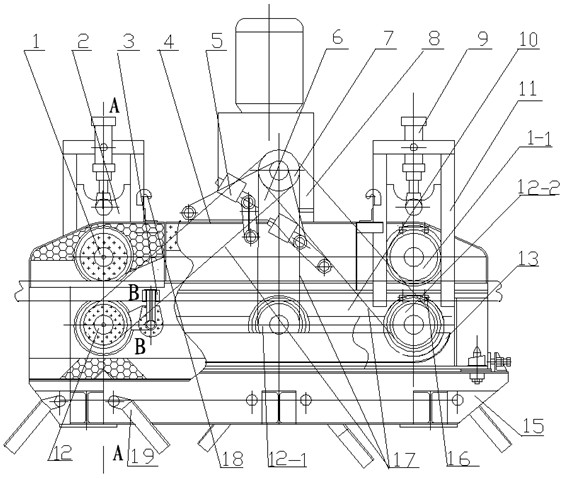

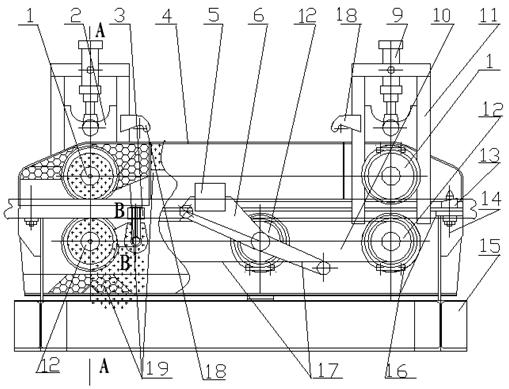

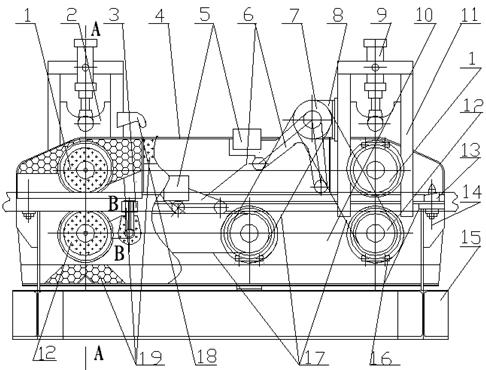

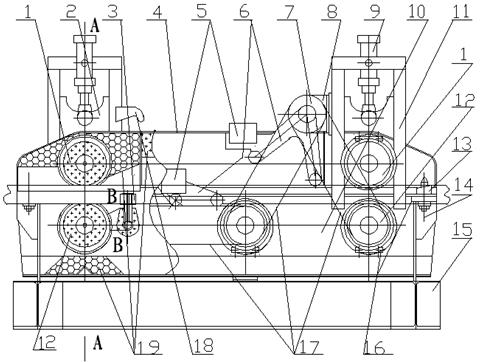

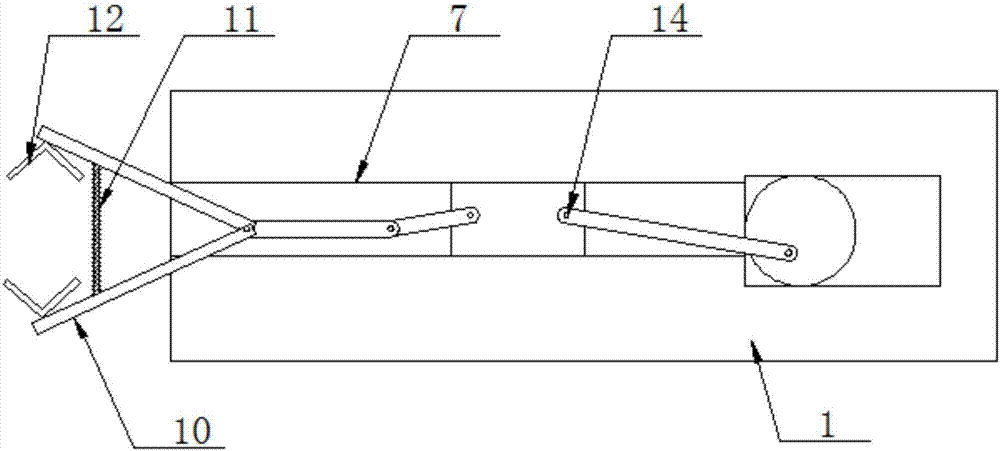

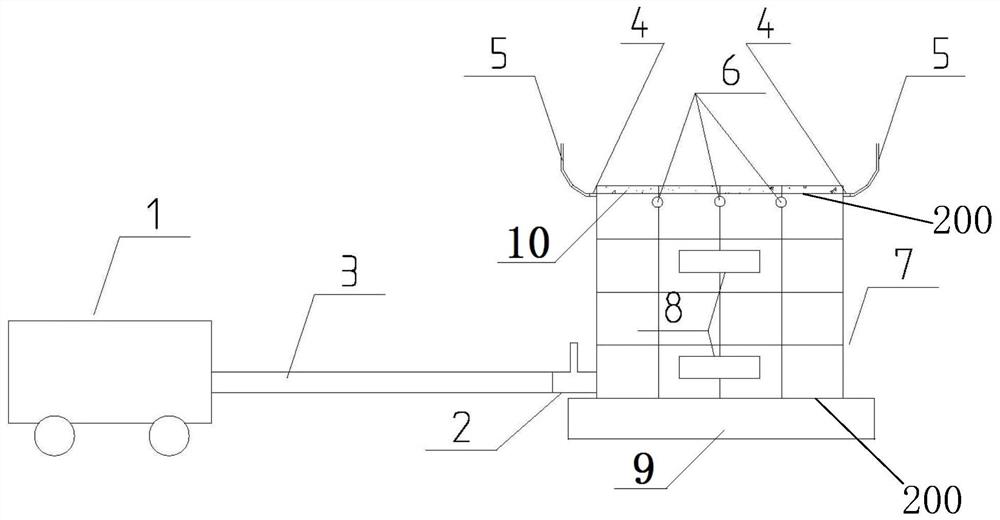

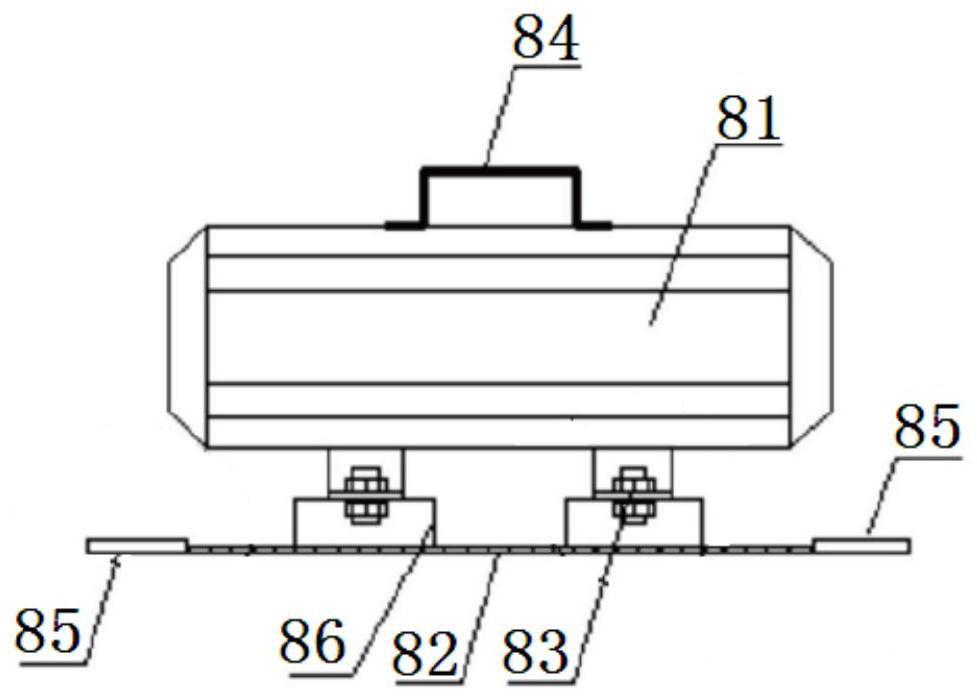

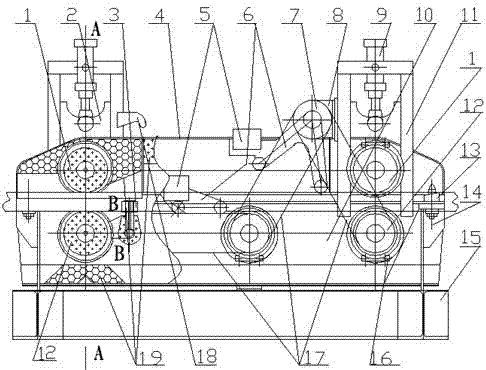

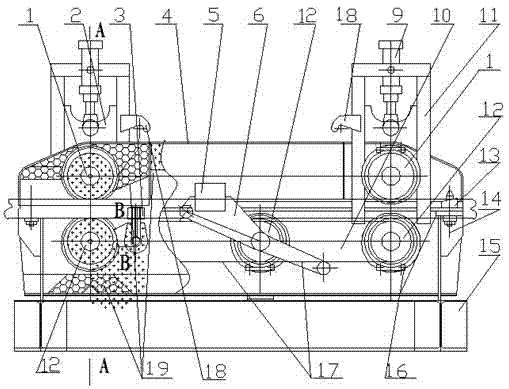

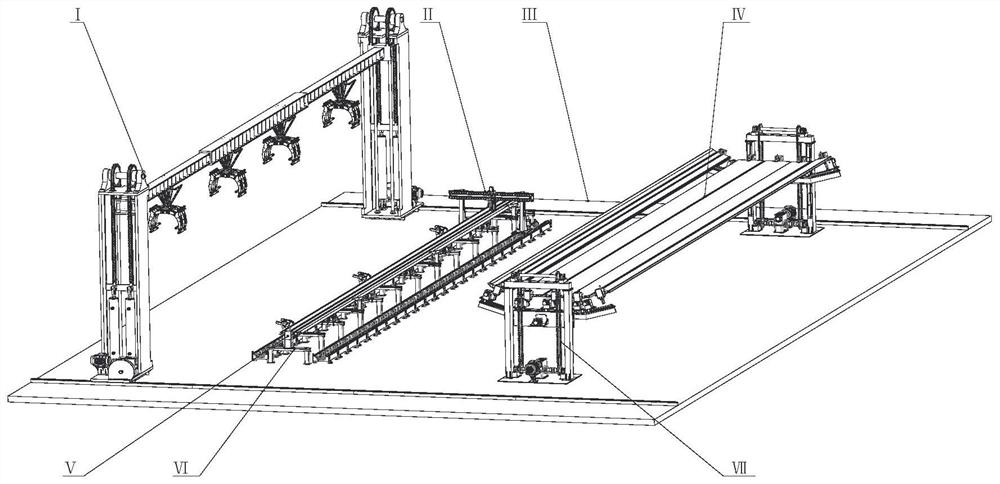

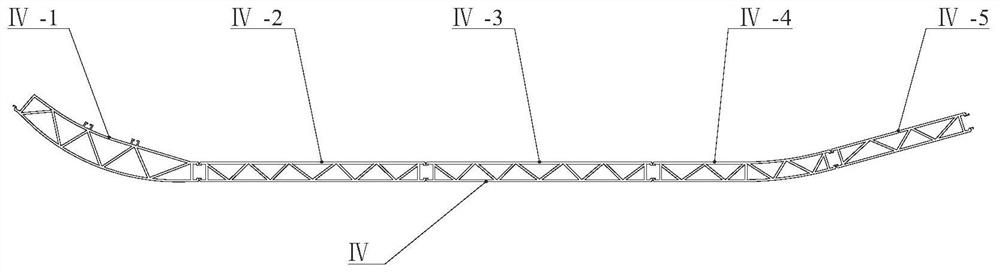

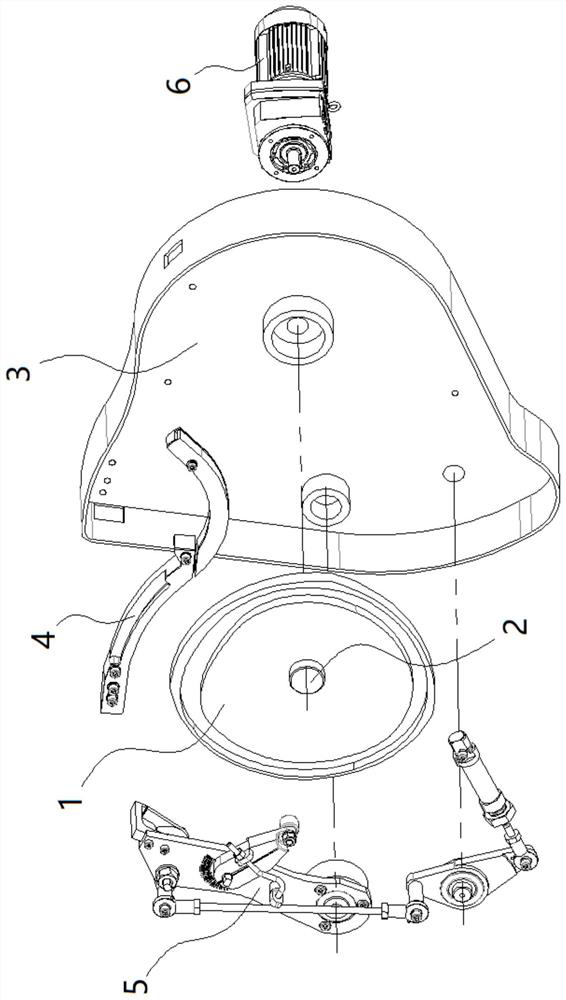

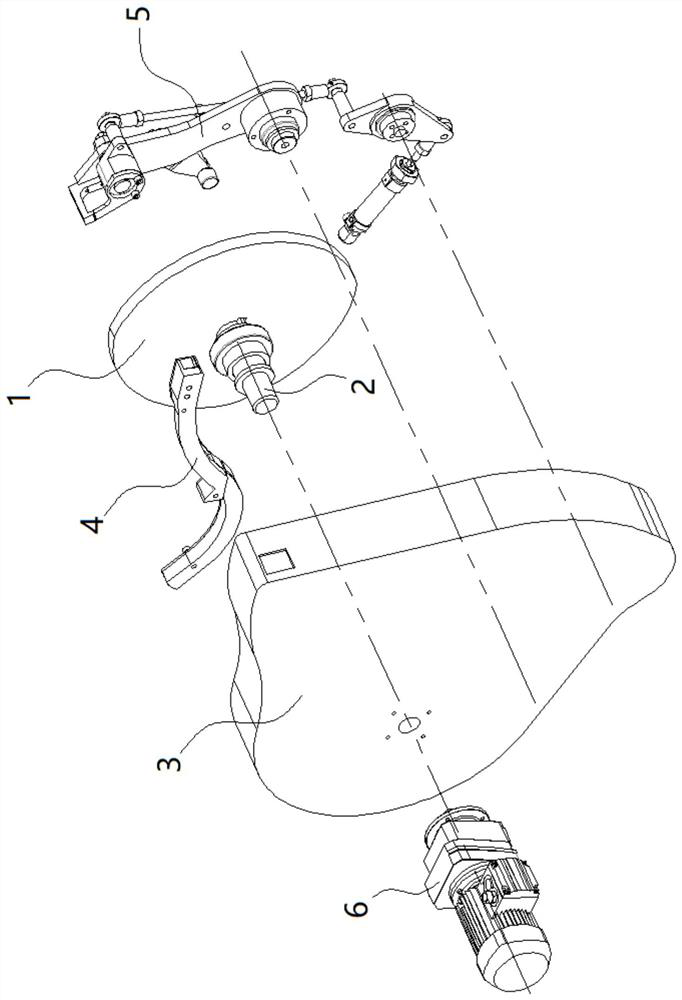

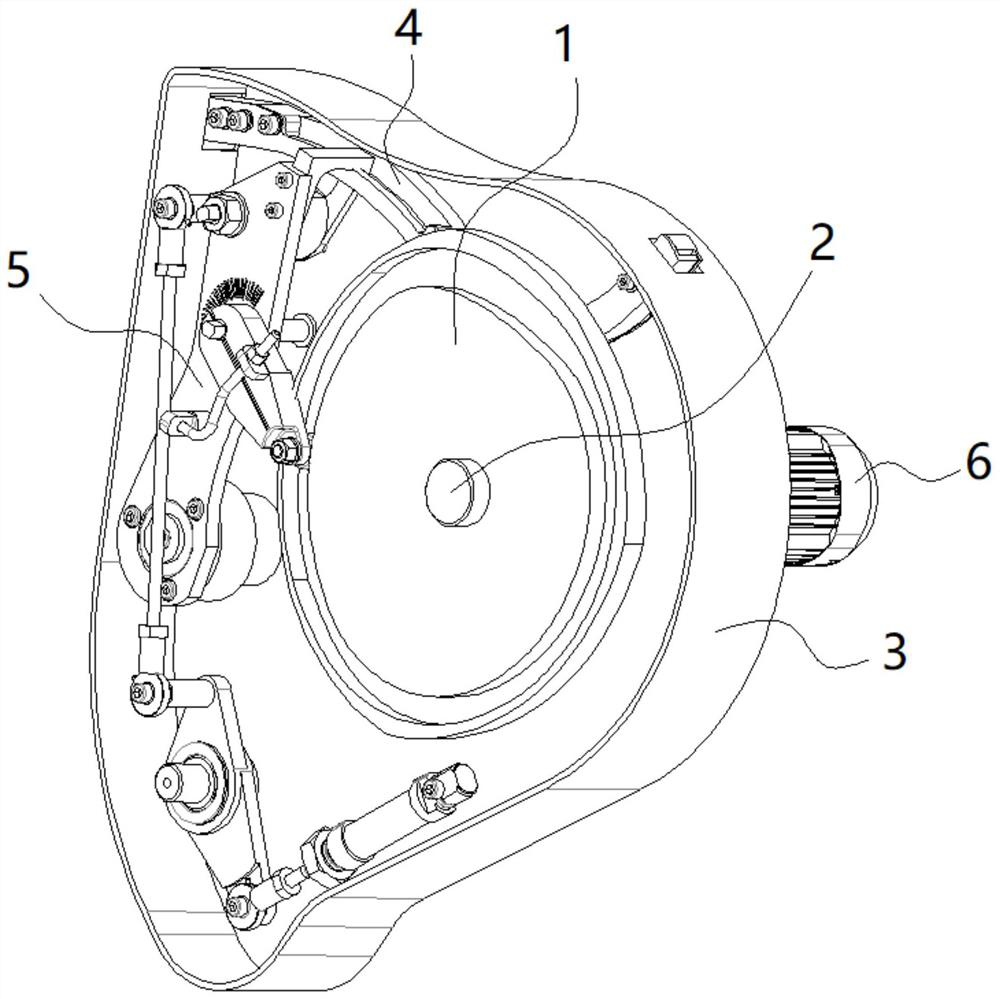

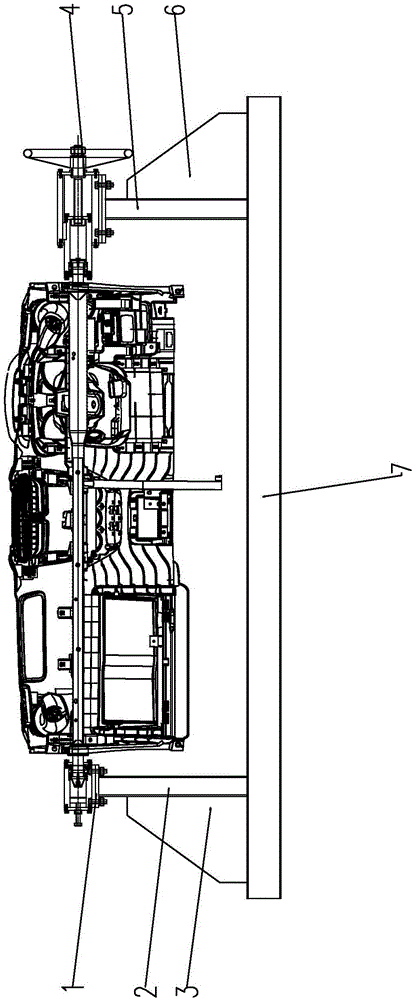

Self-propelled green bean combined harvester

The invention discloses a self-propelled green bean combined harvester. The self-propelled green bean combined harvester is characterized by comprising a chassis, a sorting and cleaning mechanism, a header, a straw smasher and a self-unloading storage bin. A power mechanism, a driving cab and the sorting and cleaning mechanism are mounted on the chassis, a travelling mechanism is mounted at the lower end of the chassis, the self-unloading storage bin is connected at the tail end of the chassis, the header is hinged at the front end of the sorting and cleaning mechanism, a cutting and conveying mechanism is arranged at the front end of the header, a multi-wedge toothed belt type picker is arranged in the header, and an adjusting oil cylinder is connected between the header and the sorting and cleaning mechanism. The self-propelled green bean combined harvester has the advantages that the sorting and cleaning mechanism is used for separating picked green beans from leaves and weeds mixed therein and feeding the cleaned green beans into the self-unloading storage bin, the leaves and weeds are smashed to return to the field by the straw smasher, the green beans are not damaged when passing a soft clamper, clamping is reliable and quality of the green beans is greatly improved.

Owner:海门市万科保田机械制造有限公司

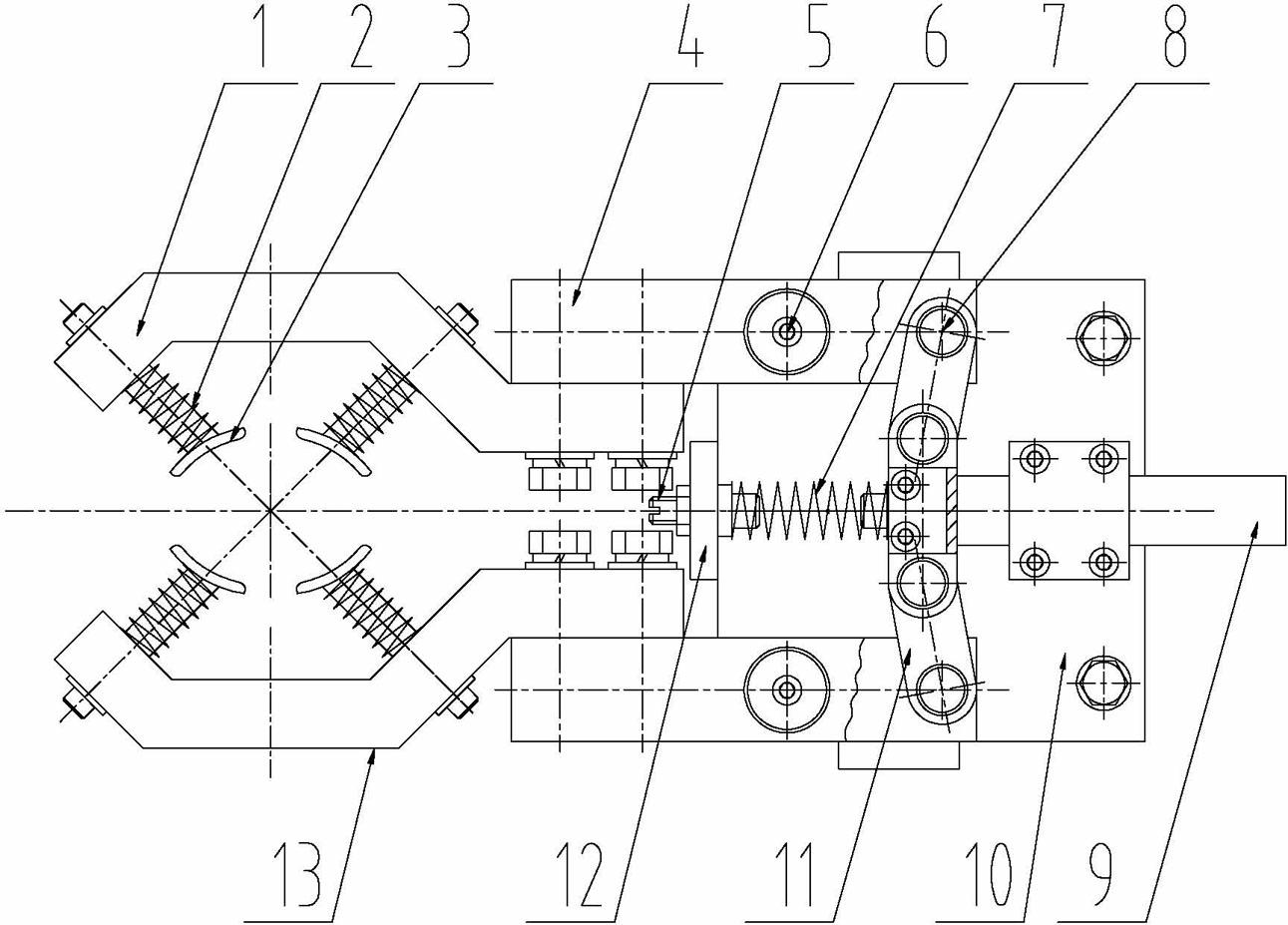

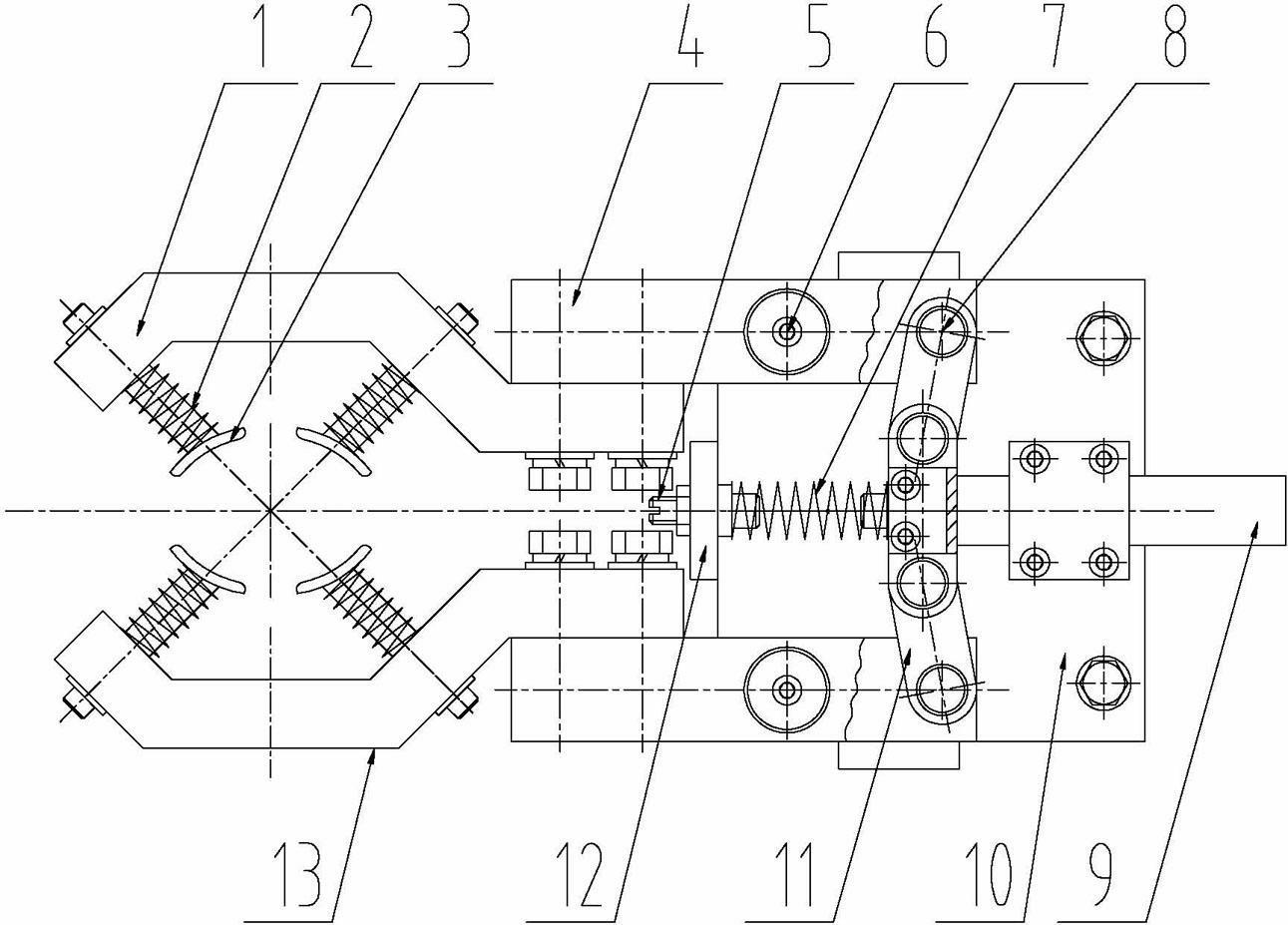

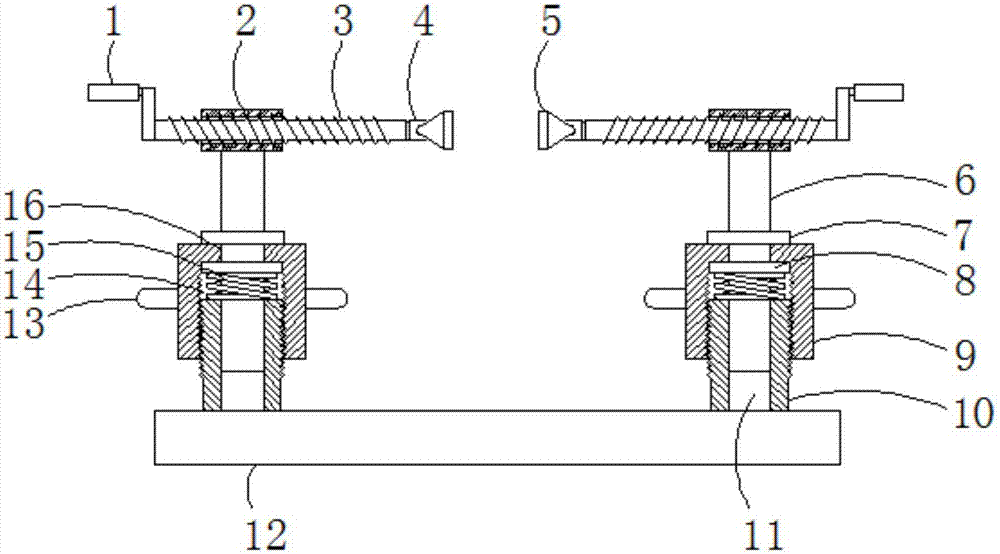

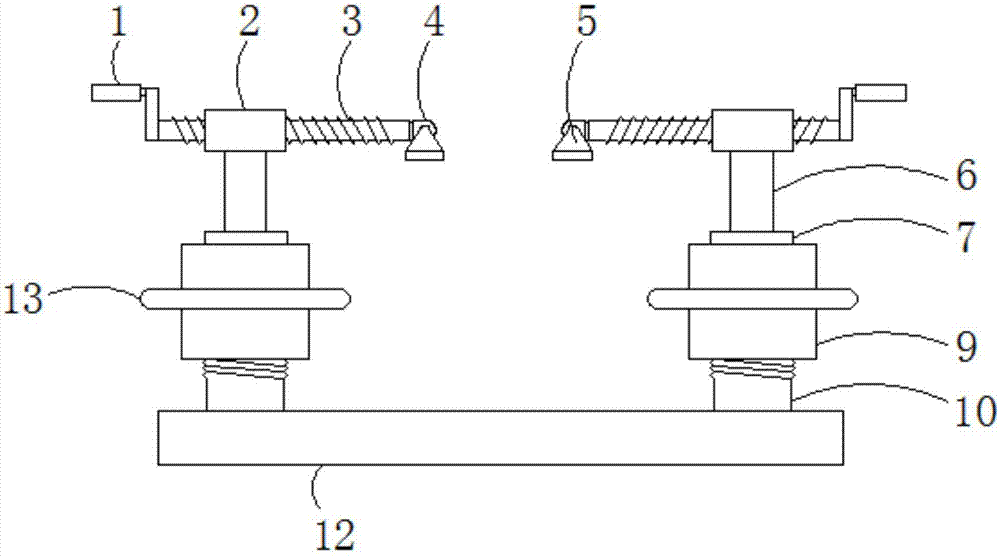

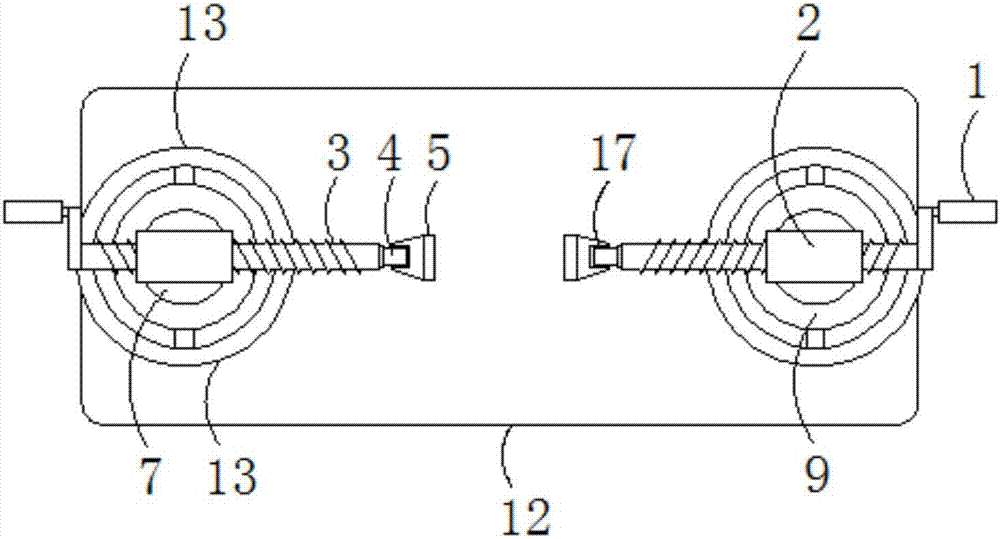

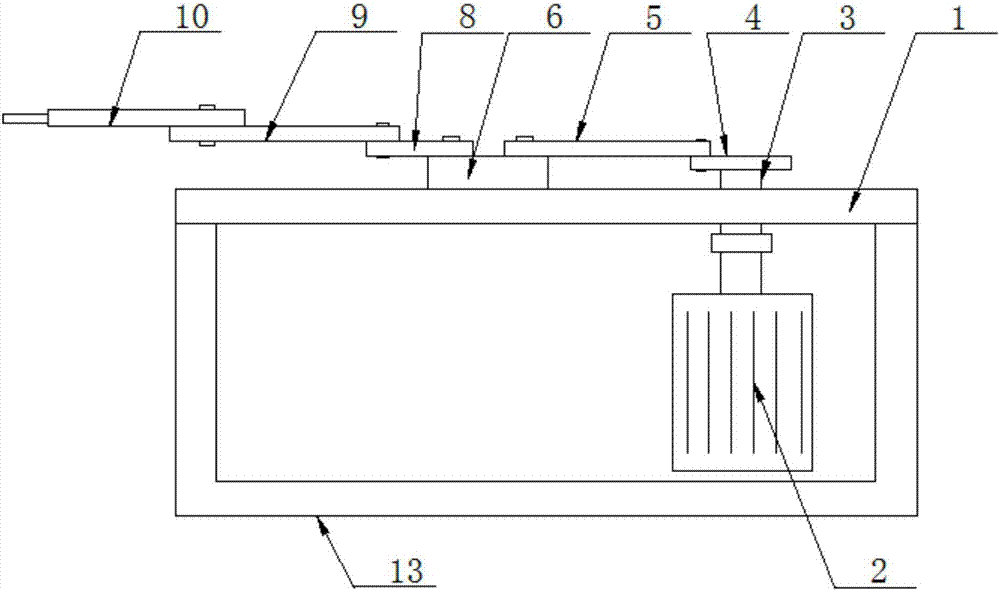

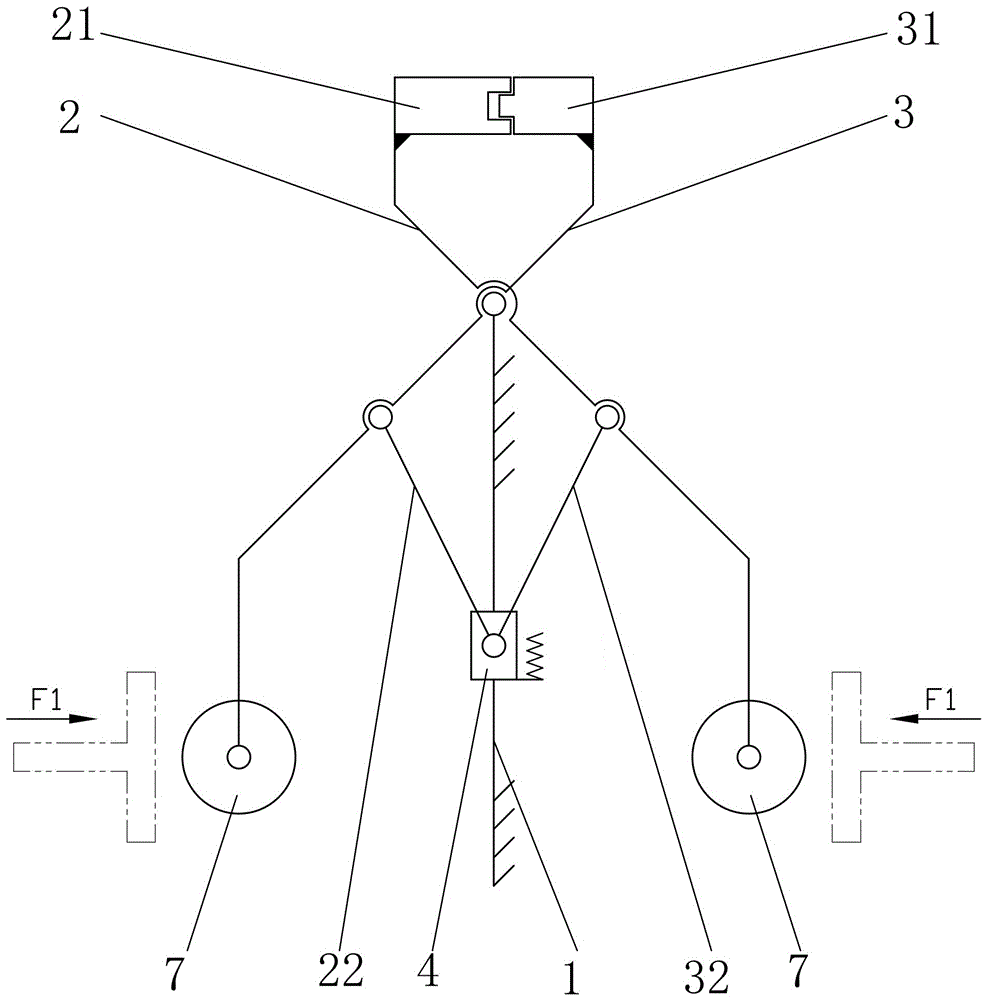

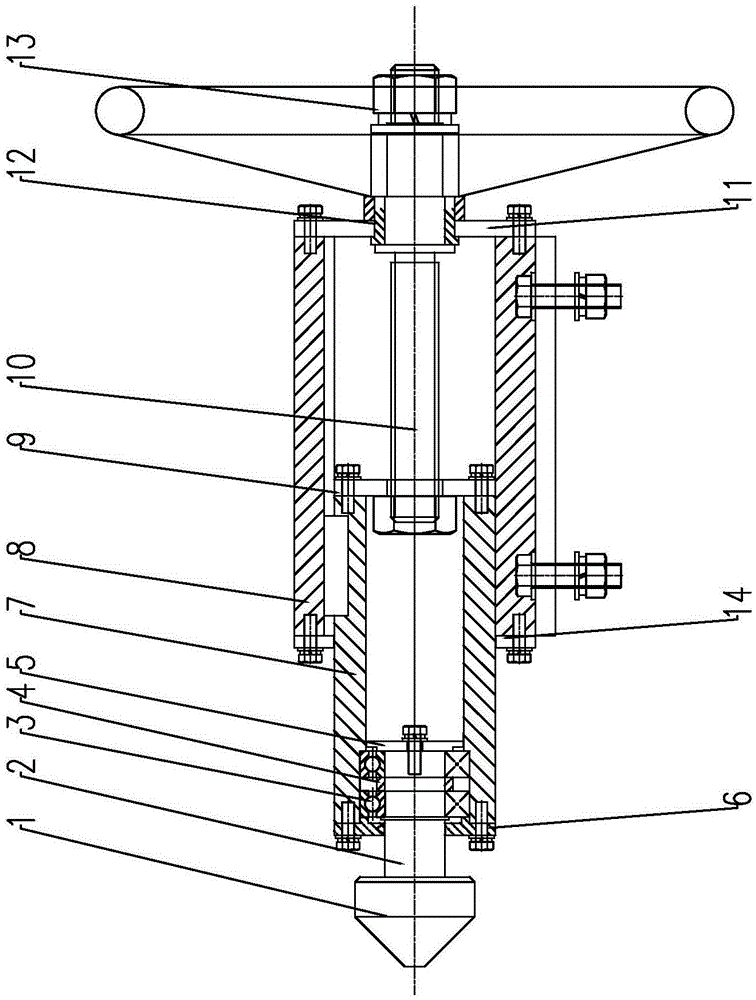

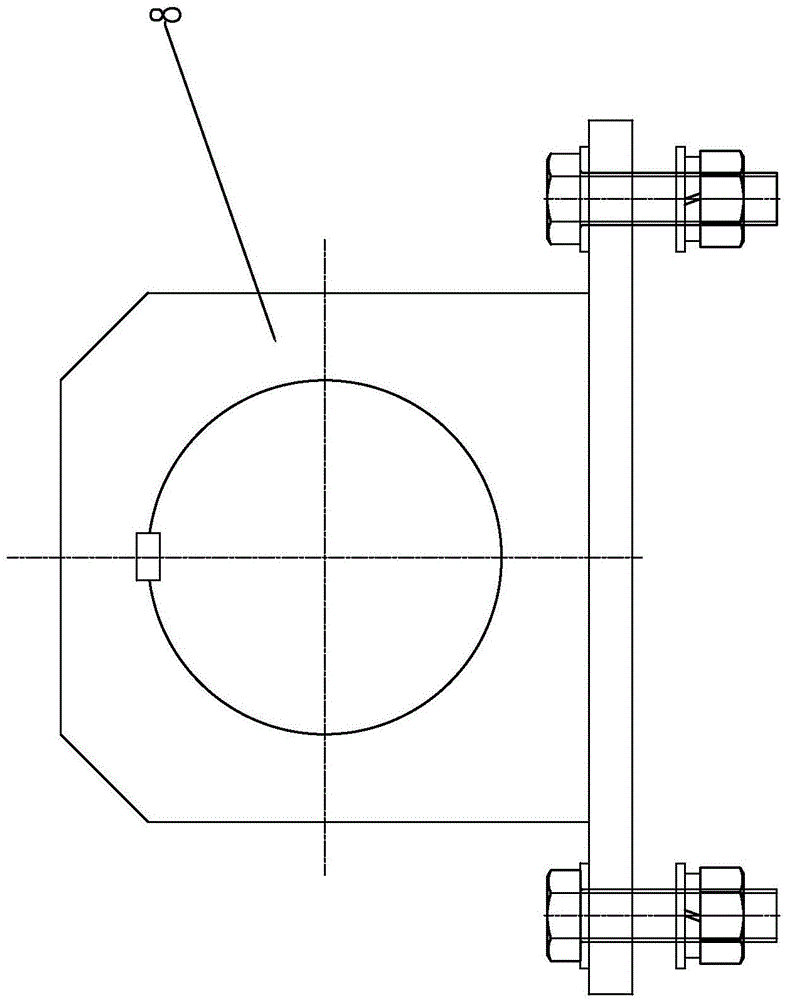

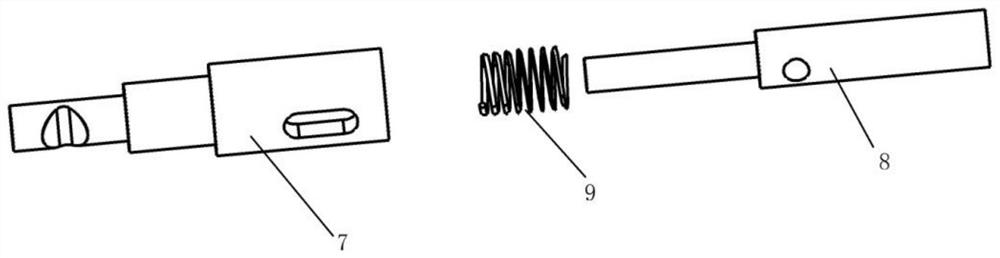

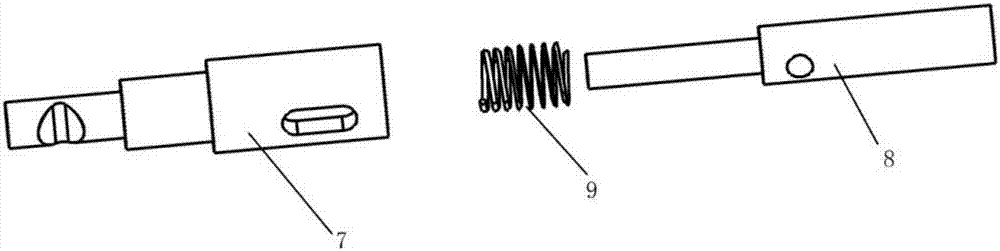

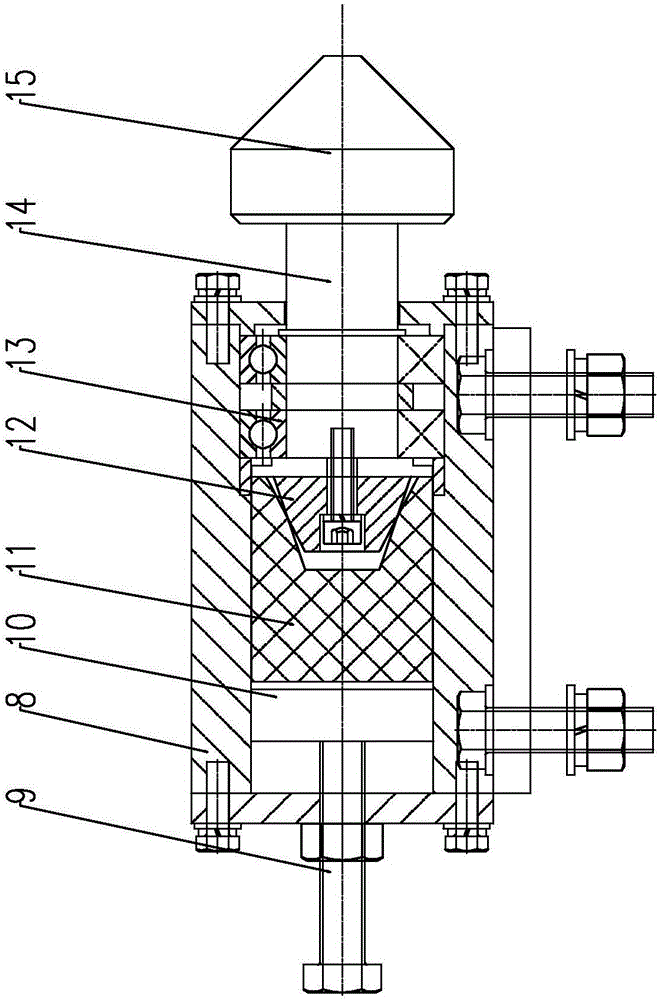

Clamper for cylindrical fine-dried noodles

ActiveCN102424137AAppropriate clamping forceDungeon Tight GuaranteePackagingEngineeringMechanical engineering

The invention discloses a clamper with suitable clamping force for cylindrical fine-dried noodles. The clamper is characterized by comprising a base (10). A push rod (9) and a fixing block (12) are arranged on the base (10), a clamping spring (7) is arranged between the push rod (9) and the fixing block (12), two connecting rods (11) are symmetrically hinged on the push rod (9), the other end of each connecting rod (11) is respectively hinged on two support arms (4) through connecting pins (8), the support arms (4) are arranged on the base (10) through support shafts (6), and the two support arms (4) are respectively provided with a grabhook (13) for clamping the cylindrical fine-dried noodles. The clamper disclosed by the invention has the advantages of simple structure, suitable force for clamping the fine-dried noodles and guarantee on stamping orderliness and vibrating closeness for the fine-dried noodles through machines.

Owner:KEMEN NOODLE MFG CO LTD

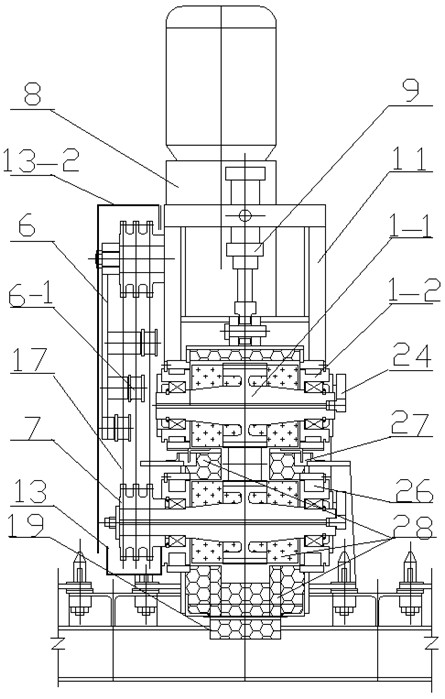

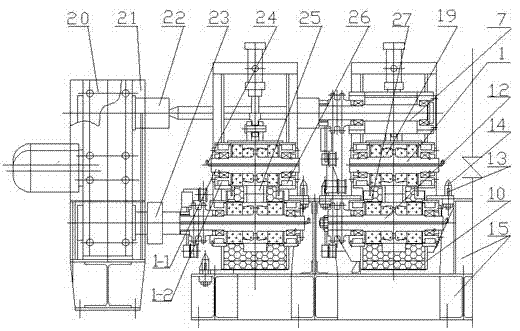

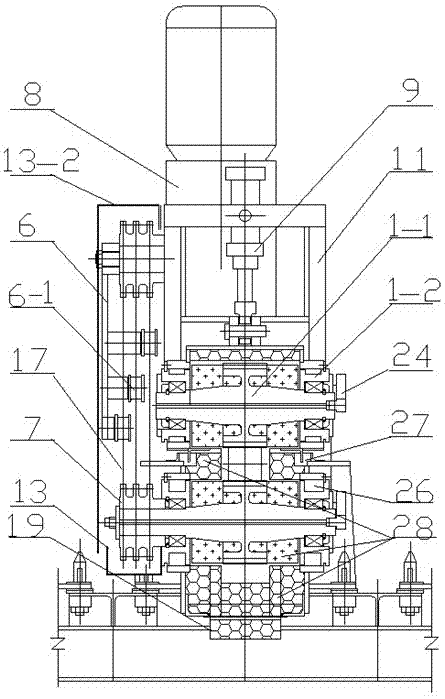

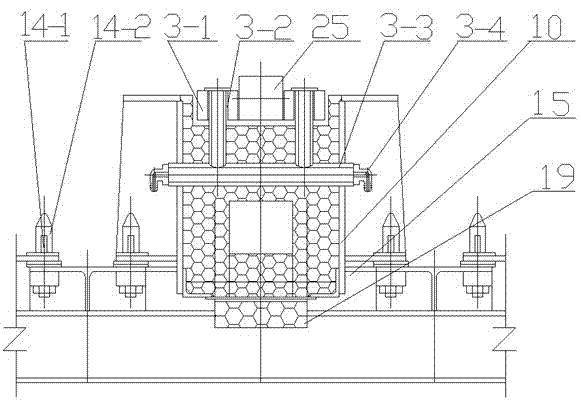

Underdrive-concentrated withdrawal and straightening machine with thermal insulation device

InactiveCN101961770AShorten the length of the roll bodyGuaranteed normal operationThermal insulationEngineering

The invention provides an underdrive-concentrated withdrawal and straightening machine with a thermal insulation device, which comprises a driving device and is characterized in that a first driving roller, a second driving roller and a third driving roller are arranged on a withdrawal and straightening machine base lined with refractory castables, a first driven roller and a second driven roller are respectively arranged above the first driving roller and the third driving roller and are driven to do lifting movement in a lifting guide cover device to ensure that the first driving roller together with the first driven roller and the third driving roller together with the second driven roller to clamp and deliver steel billets to move and to be straightened. The invention has the advantages of realizing and improving the working conditions and the surrounding environment of the withdrawal and straightening machine, reducing water energy consumption, preventing excessive heat dissipation and realizing high degree of sealing in the whole process of heat transferring in order to achieve the purposes of decreasing the heat dissipation of a hot billet, improving charging temperature, reducing energy consumption and steel consumption and improving product quality and provide conditions for the hot charging and hot conveying of some steel types in a protective atmosphere and the direct rolling of the steel billet.

Owner:何学才

Fixing device for machining end covers of motorcycle engines

InactiveCN107378556AEffective and stable clampingEasy to adjust at multiple anglesPositioning apparatusMetal-working holdersEngineeringCounterbore

The invention discloses a fixing device for motorcycle engine end cover processing, which comprises a base. The inside is provided with a thread groove, and the thread groove is screwed and connected with the external thread on the surface of the fixing seat. The upper surface of the gland is provided with a through hole, and the through hole communicates with the thread groove. The inside of the fixing seat is provided with A counterbore, the counterbore is arranged vertically, and a column is arranged inside the counterbore, and the column vertically extends through the through hole to the outside of the gland. The present invention adopts two oppositely arranged clamping mechanisms, and adopts the up-and-down expansion and contraction of the column and the horizontal opposite movement of the screw rod to realize the clamping of the workpiece, which can achieve effective and stable clamping of workpieces with various shapes, and is convenient for multiple angles of the workpiece The adjustment improves the workpiece clamping range and effectively improves the processing efficiency.

Owner:湖州精特新材料有限公司

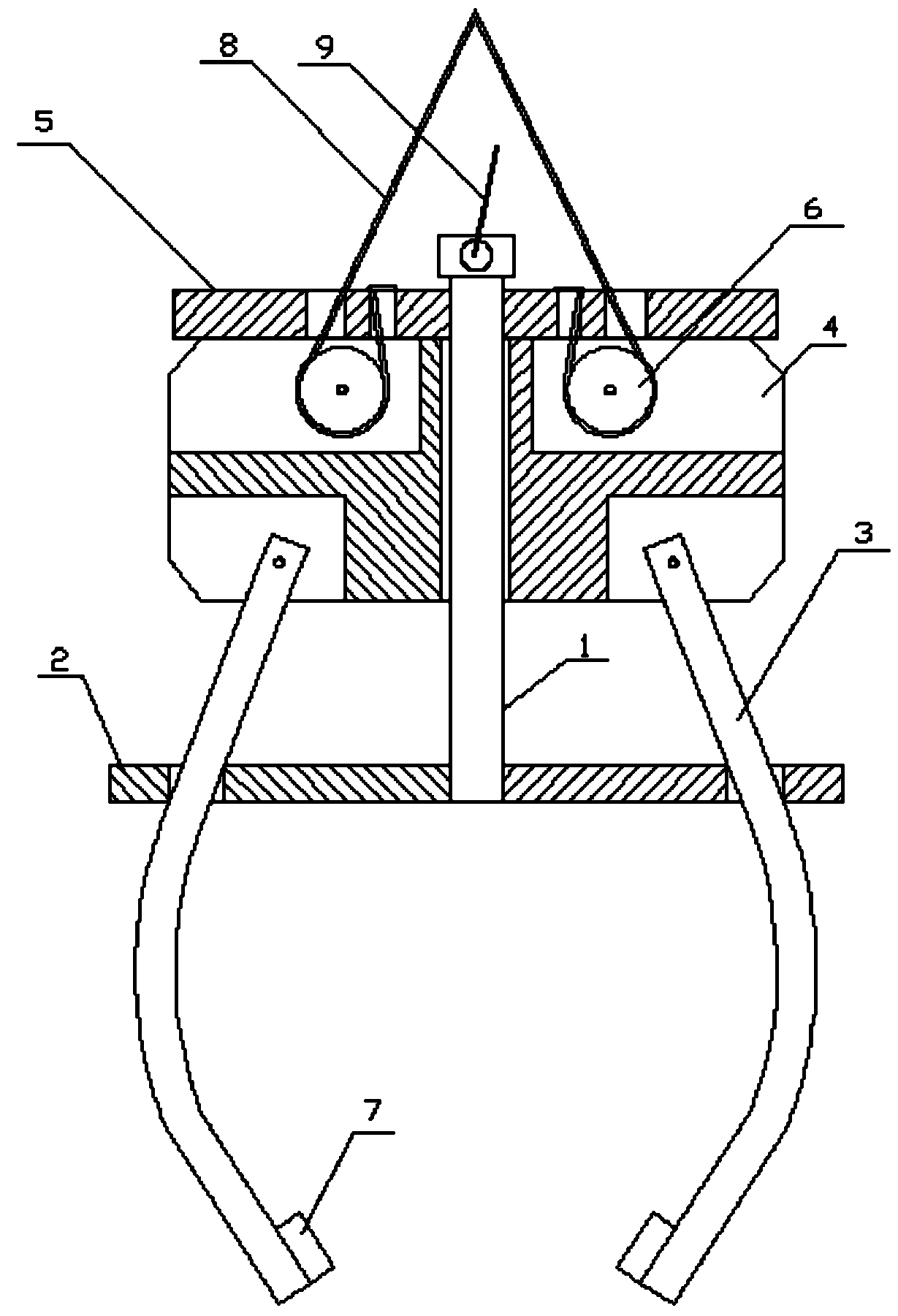

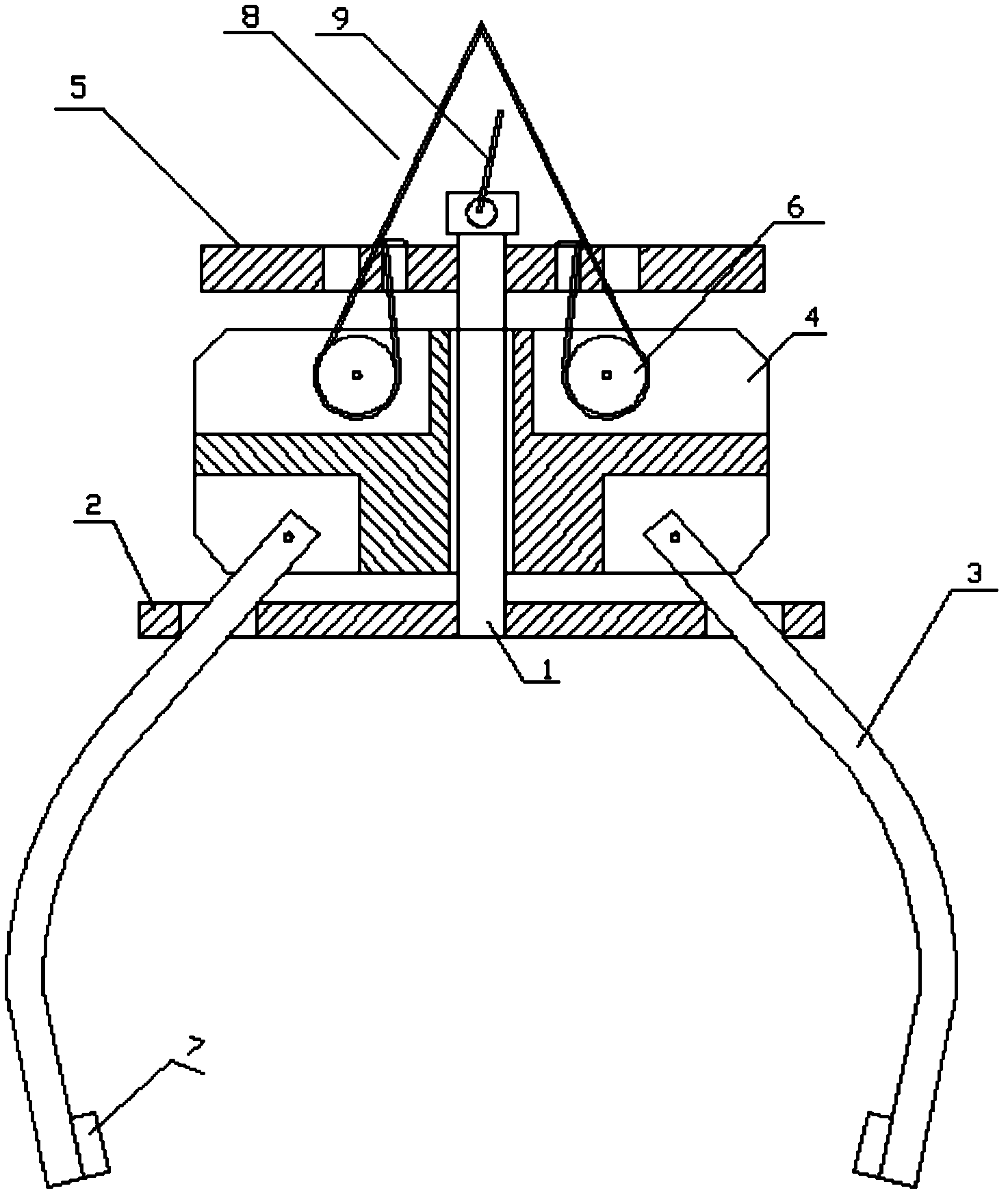

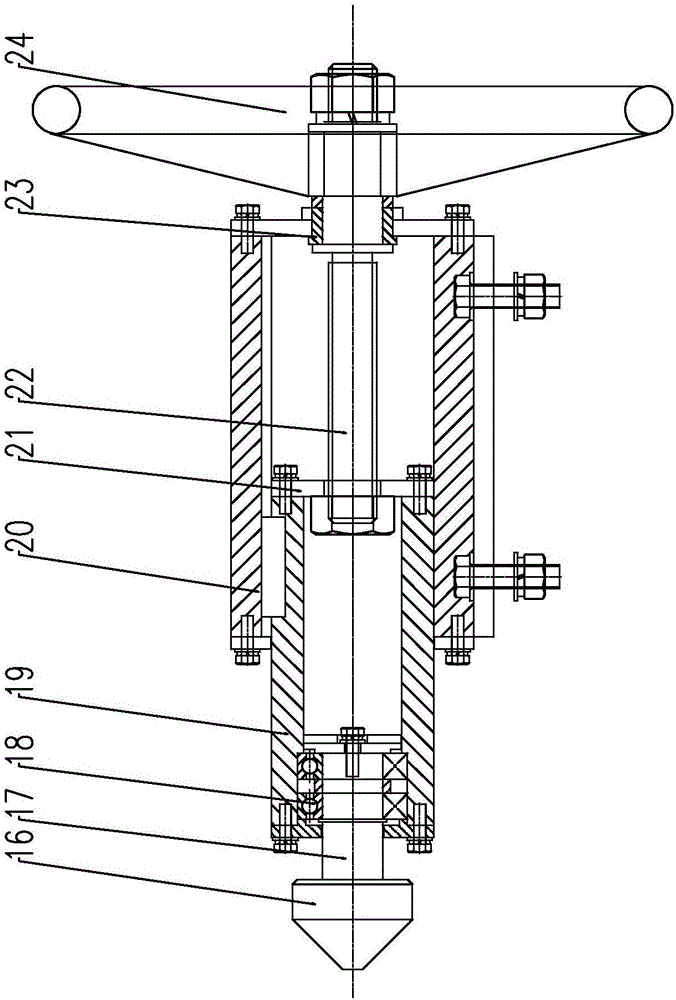

Picker and method for picking targeted object

The invention relates to the field of machinery, in particular to a picker and a method for picking a targeted object. A self-locking function is produced due to the structure of the picker, and the phenomenon that pliers arms of the picker are loosened because the targeted object is too heavy is avoided, so the picker can pick the object at a long distance reliably when power is not sufficient. The picker comprises a guide device, a pliers seat, a lifting and pulling piece, and a clamping device; the guide device comprises a guide column and a guide plate; the lower end of the guide column is fixedly connected with the guide plate; the pliers seat is provided with a through hole or a notch which is penetrated from the upper part of the pliers seat to the lower part of the pliers seat, so the guide column can slidably pass through the through hole or the notch; the lifting and pulling piece comprises at least one lifting and pulling rope which is provided with a free end and a connection end which is connected with the pliers seat; the clamping device comprises at least two pliers arms; the upper end of each pliers arm is pivoted with the pliers seat; the pliers arms can slidably pass through a guide hole of a guide plate respectively to ensure that the lower end of each pliers arm is selectively unfolded or folded relative to a central shaft of the picker; and each pliers arm is arch-shaped, and the opening of the arch faces the central shaft of the picker.

Owner:BEIJING POLYTECHNIC

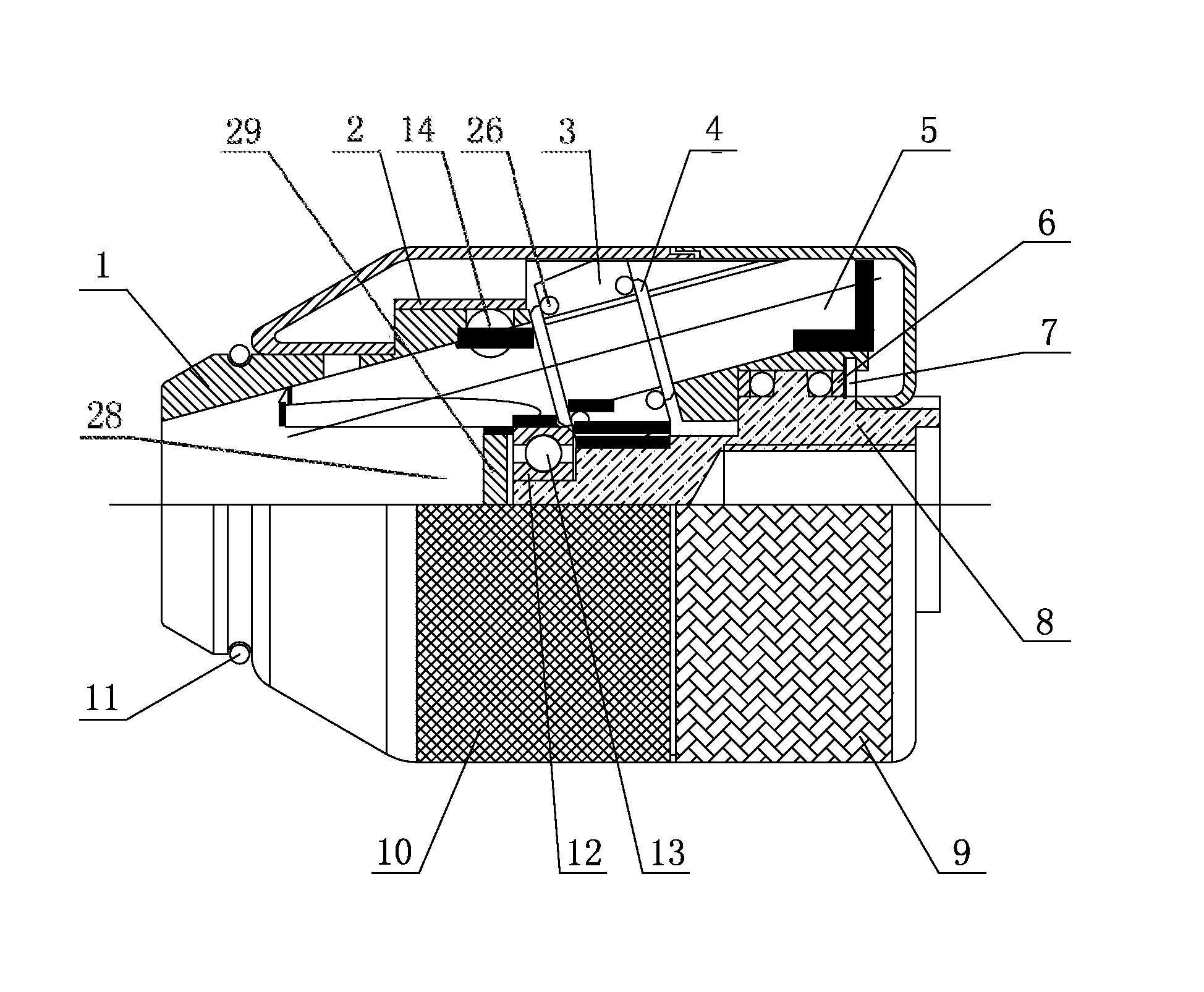

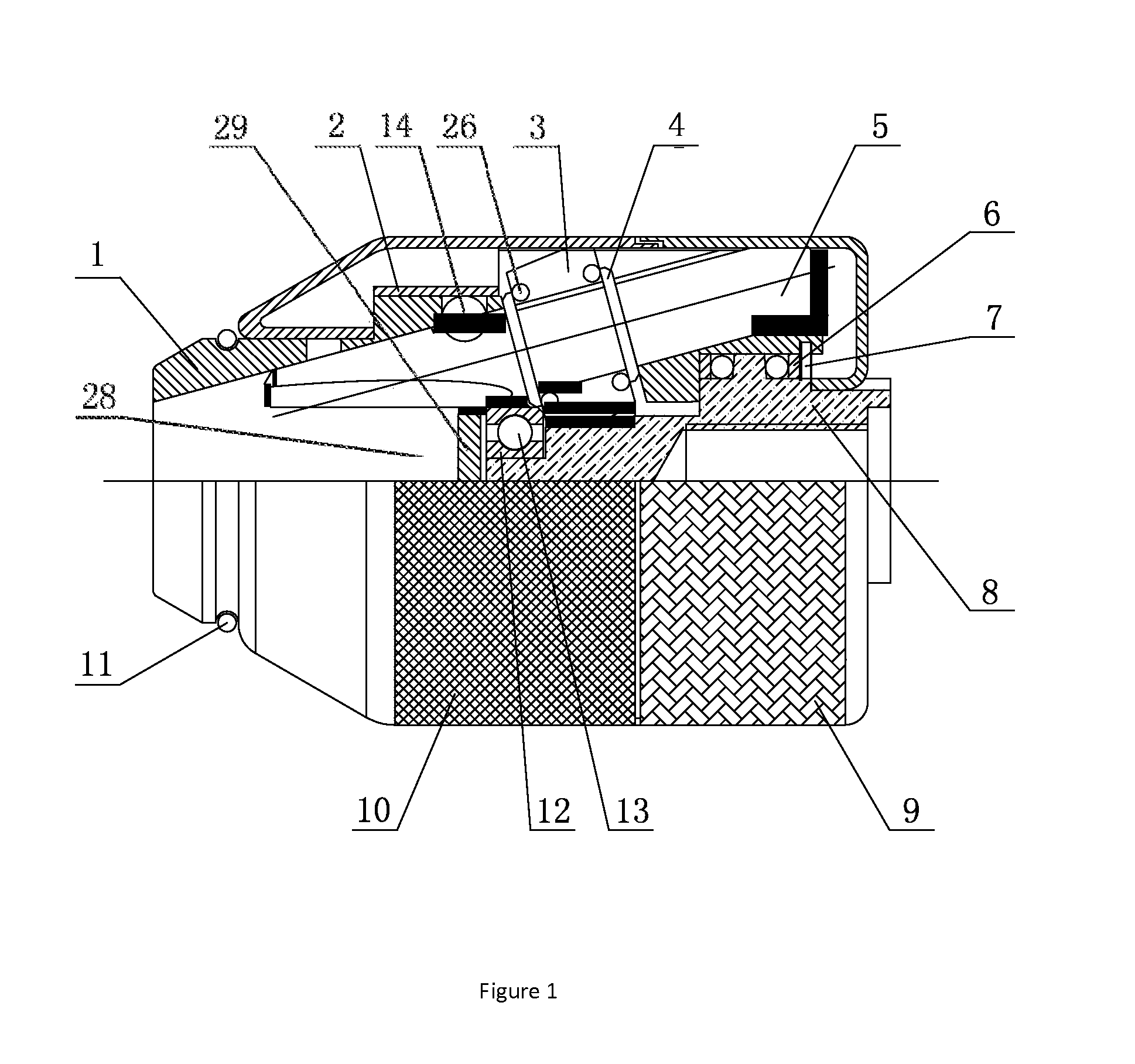

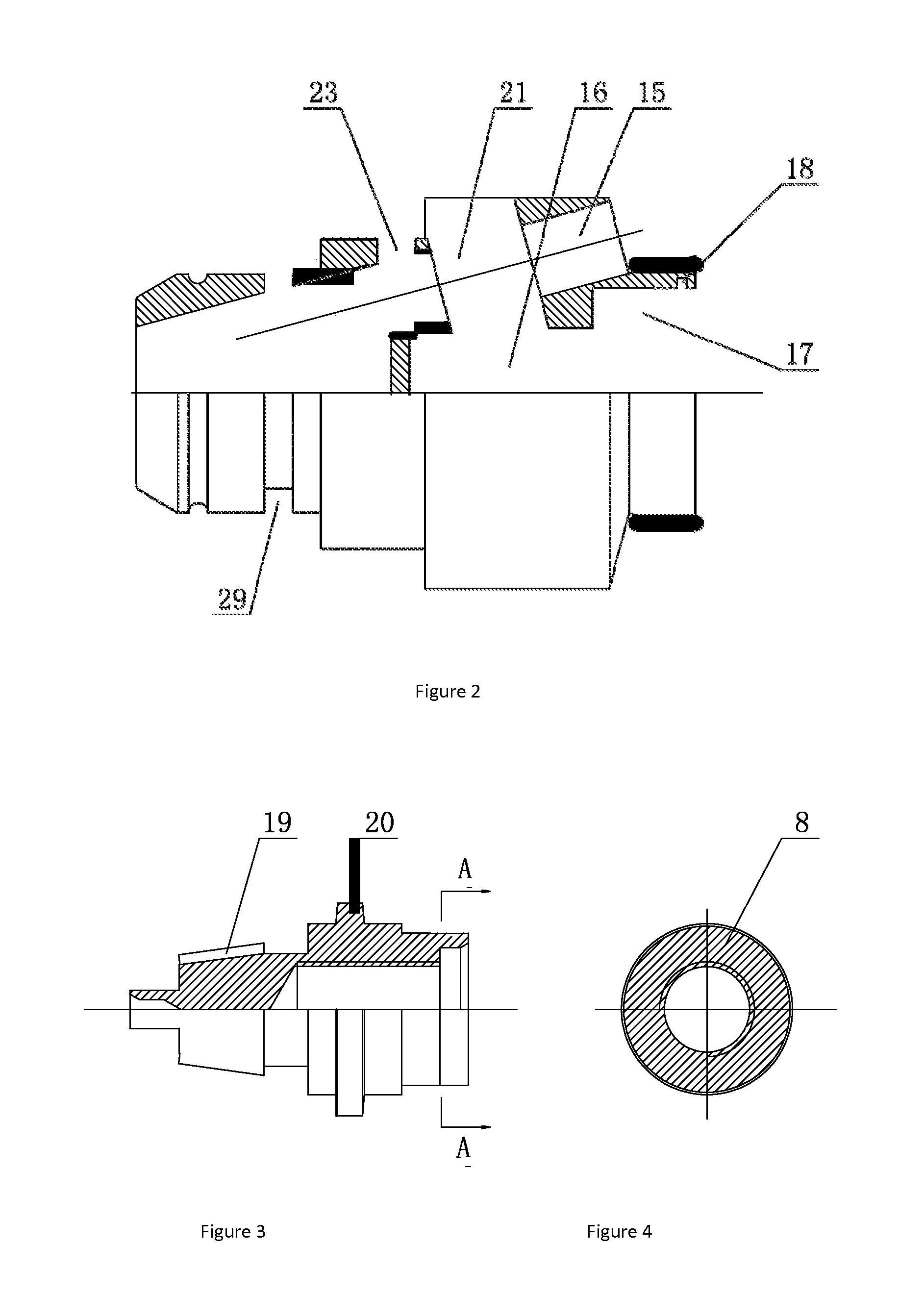

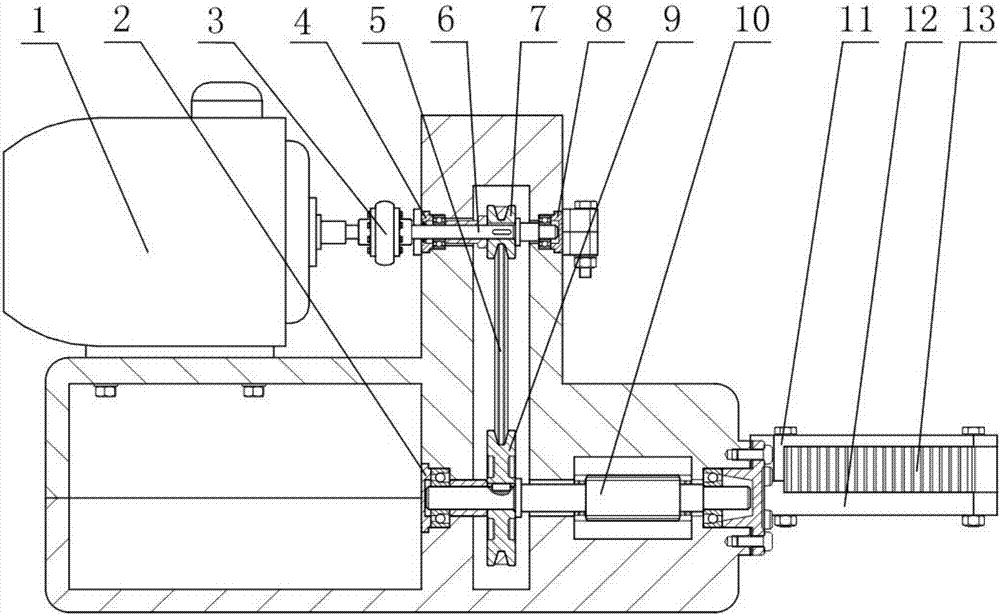

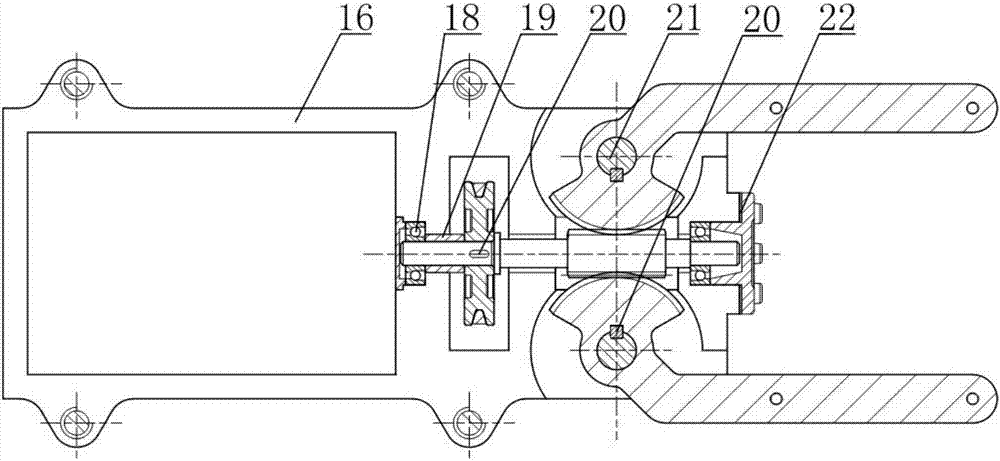

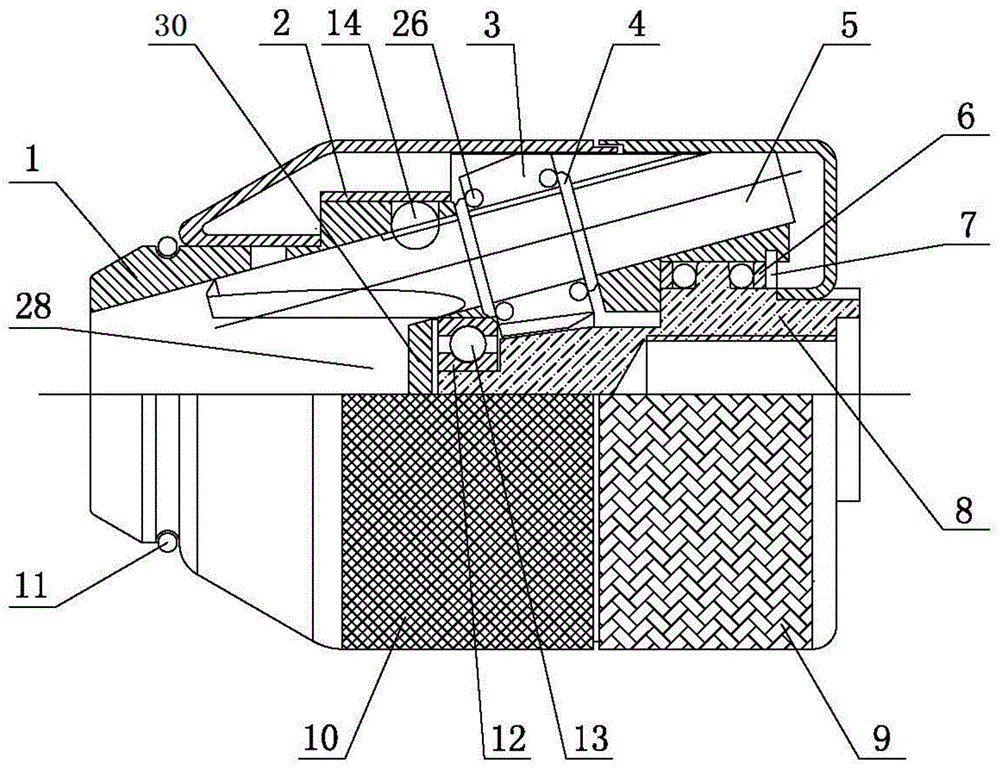

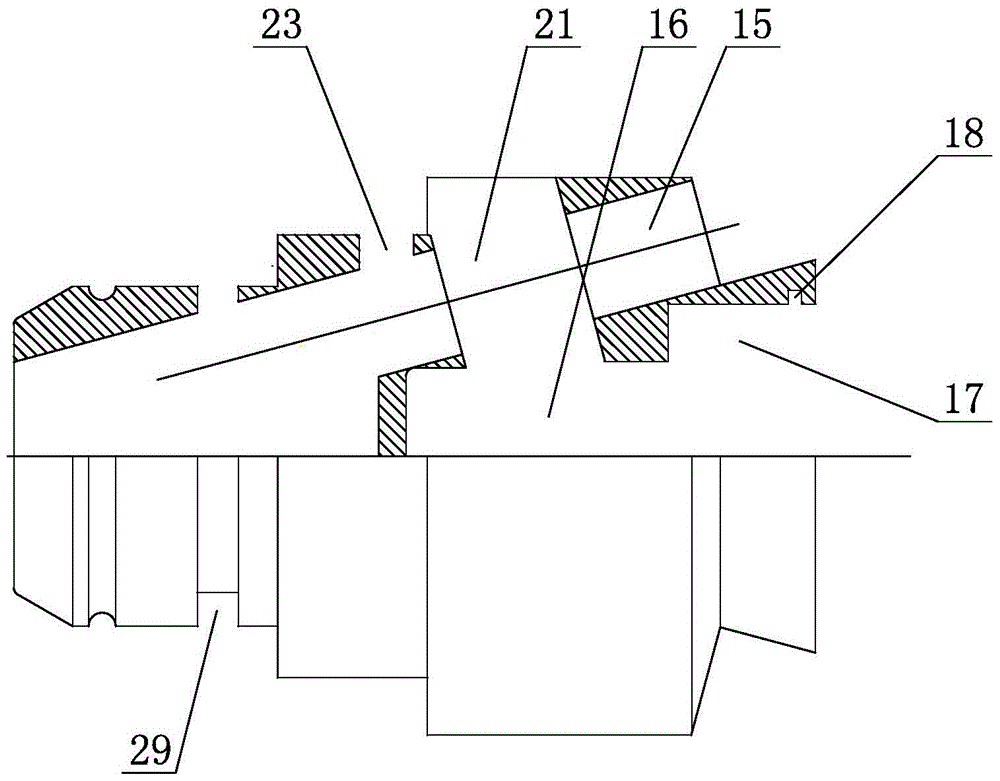

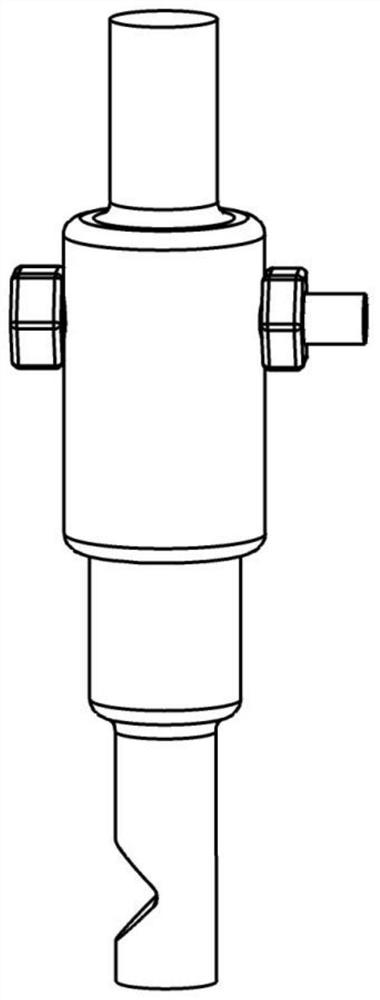

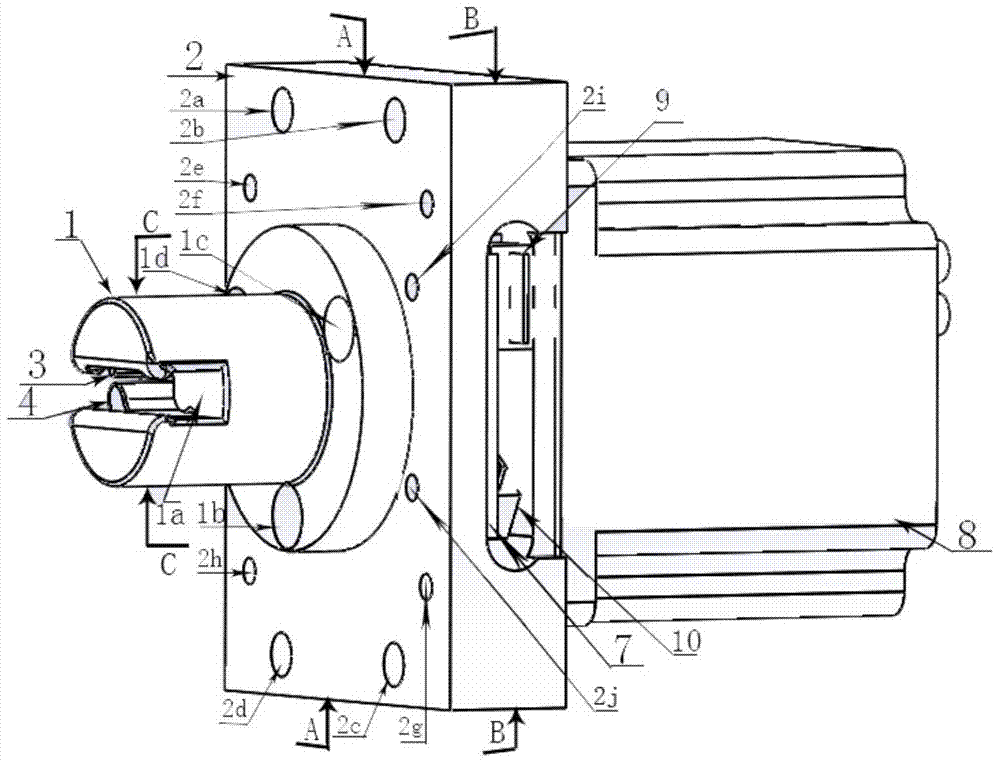

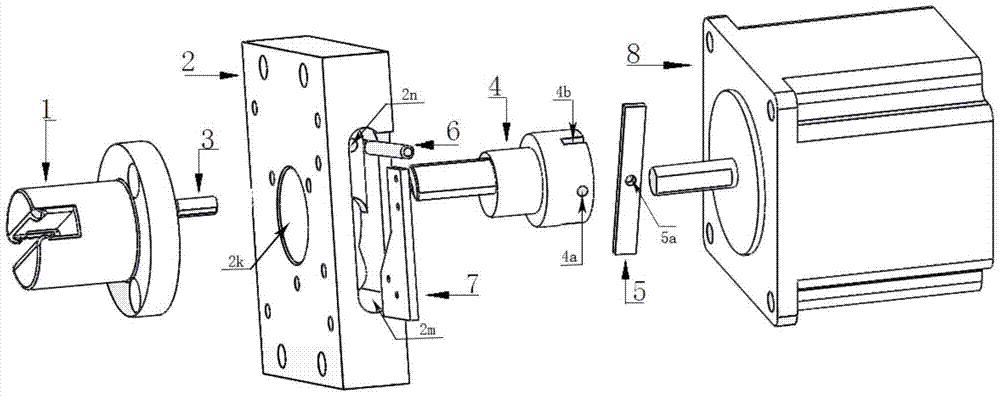

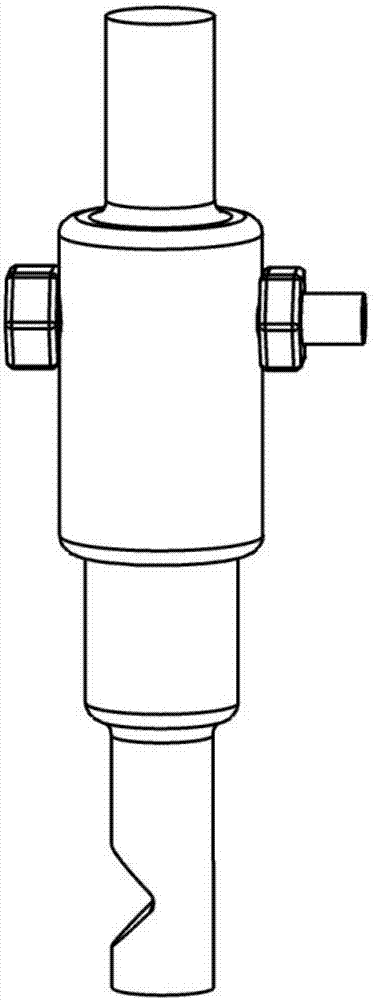

Electric pinch valve

ActiveCN105508650AAdjustable positionAppropriate clamping forceDiaphragm valvesOperating means/releasing devices for valvesPeritoneal dialysisPinch valve

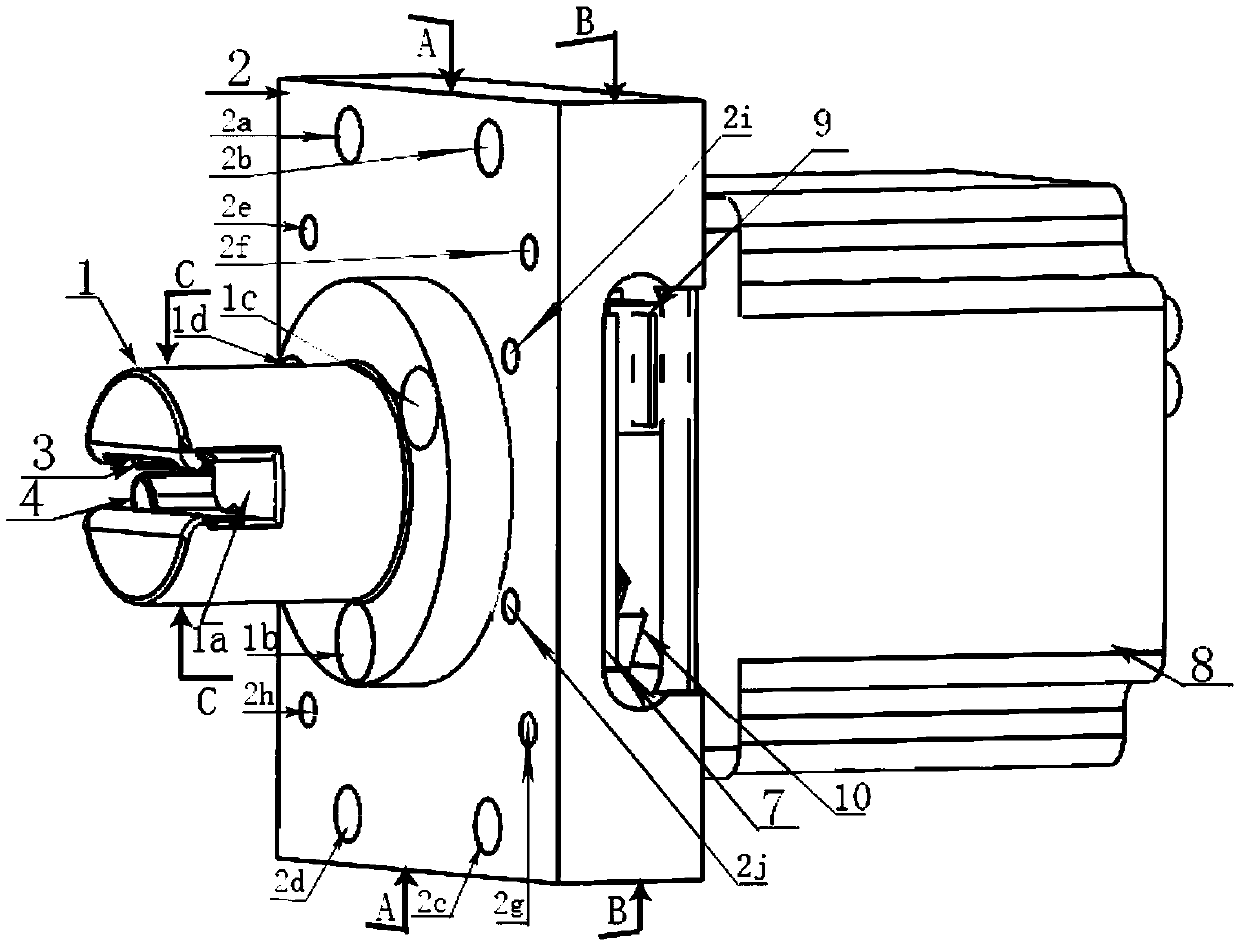

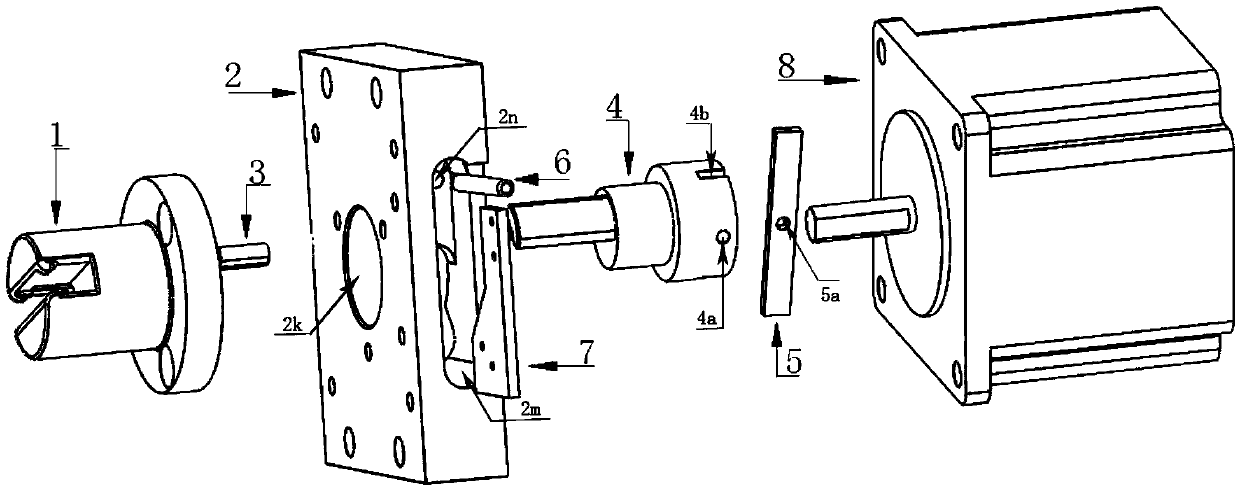

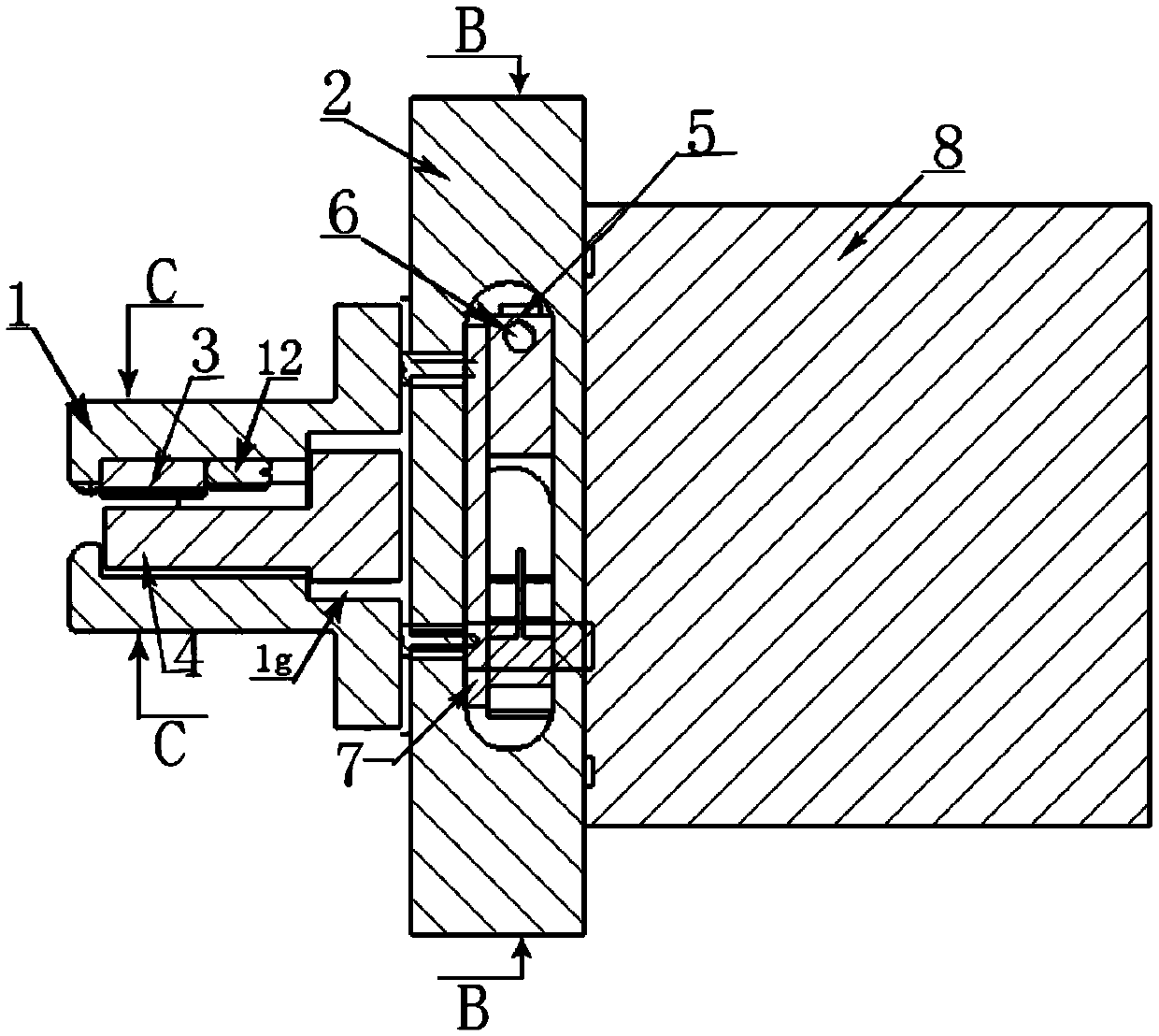

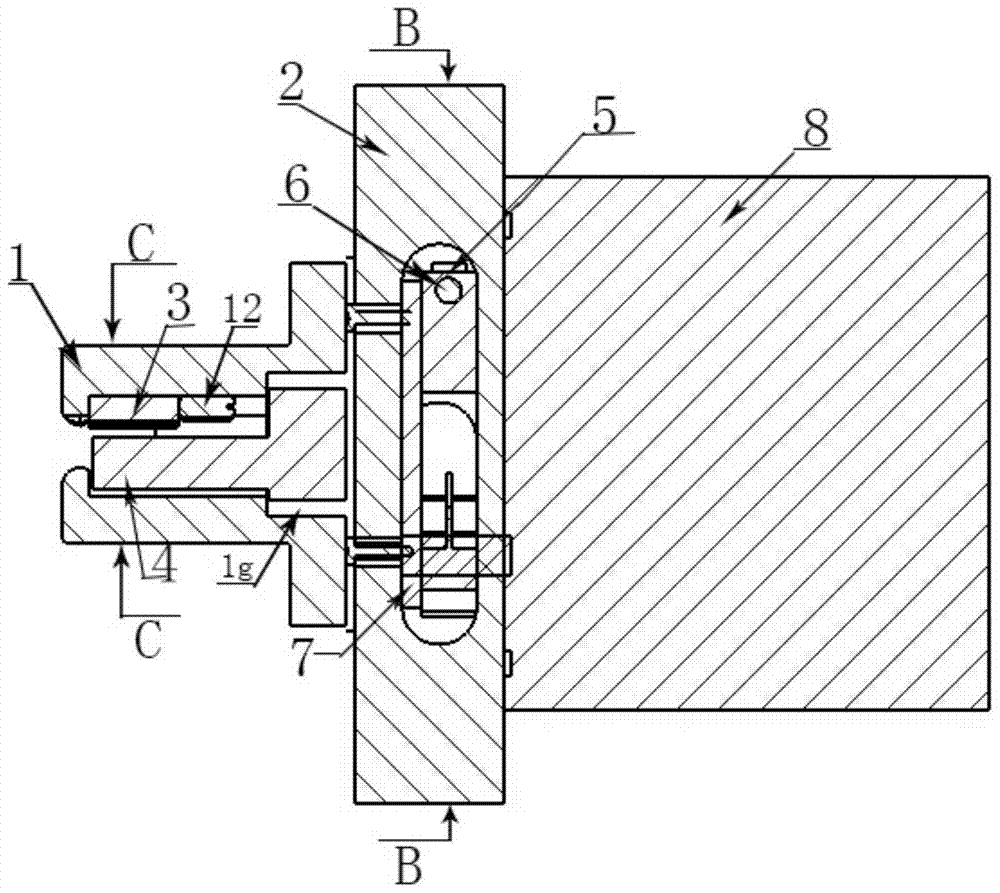

The invention relates to an electric pinch valve. A stepping motor rotates forwardly and reversely to drive the pinch valve to be opened and closed, so that the pinch valve can loosen or clamp an elastic hose, thereby controlling the on-off state of the fluid in the elastic hose. The electric pinch valve comprises a hose clamp port assembly, a movable valve assembly, a stopping device assembly and a connecting plate (2), wherein the hose clamp port assembly is installed in the central position of the front surface of the connecting plate (2); the movable valve assembly is inserted into a central circular hole (2k) on the back surface of the connecting plate (2) and fixed to the back surface of the connecting plate (2); the stopping device assembly is inserted into an elliptical cavity (2m) on the right side surface of the connecting plate (2); a rotor (4) and a rotor plate (5) of the movable valve assembly are fixed to a motor rotating shaft and rotate coaxially; two microswitches (9, 10) installed on a switch plate (7) in the stopping device assembly are used for judging to clamp or loosen the hose; and the judgment result is used as the reference for stopping the motor. The electric pinch valve is applicable to biological artificial livers, blood cleansing machines, peritoneal dialysis machines and other medical facilities.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Underdriving progressive withdrawal and straightening machine with heat insulation device

The invention provides a progressive underdriving five-roller straightening and withdrawal machine with a heat insulation device. The withdrawal and straightening machine comprises a pair of withdrawal rollers and a pair of straightening rollers which are arranged inside a heat insulation cover, and a lower roller. Three underdriving rollers are arranged on a withdrawal and straightening machine base with a refractory castable material and transmitted by a chain wheel and are connected with a speed reducer with a variable frequency speed-regulating motor outside a production line through a coupler and a universal-joint spindle; and two upper driven rollers are arranged on a lifting guide cover pulled by a hydraulic cylinder and provided with a refractory fiber. A cantilever vertical roller is arranged on the withdrawal and straightening machine base; the diameter of the roller can be changed along with the width of casting blank; all the rollers are communicated with water to be cooled; and a plurality of withdrawal and straightening machines are arranged on an overhead base shared by the withdrawal and straightening machines through a tapered wedge. The progressive underdriving five-roller withdrawal and straightening machine has the advantages of preventing billet steel from heat dissipation and oxidation to the greatest degree, improving operating conditions of electromechanical equipment, moving the electromechanical equipment outside the production line so as to facilitate maintenance and management, preventing air leakage on a joint surface by adopting sand seal, and effectively realizing the sealing and cooling of an axial end by adopting an air knife structure.

Owner:何学才

Mechanical arm mechanism for industrial robot

InactiveCN107214718ASimple structureSimple transmission structureGripping headsFinger structureSlide plate

The invention discloses a mechanical arm mechanism for an industrial robot, and relates to the technical field of industrial robots. The mechanical arm mechanism for the industrial robot comprises a sliding plate, a motor, an output shaft, a crank, a first connecting rod, a sliding block, a rail, a second connecting rod, a rocker, fingers and a spring. The motor is arranged below the sliding plate. The motor is connected with the output shaft. The output shaft is connected with the crank. The crank is connected with the first connecting rod. The first connecting rod is connected with the sliding block. The rail is arranged on the sliding plate. The sliding block is slidably connected with the rail. The sliding block is connected with the second connecting rod. The second connecting rod is hinged to the rocker. The rocker is hinged to the two fingers. The spring is connected between the two fingers. According to the mechanical arm mechanism for the industrial robot, a finger structure and a transmission structure are simple, the mechanical arm mechanism for the industrial robot is not prone breaking down and convenient to maintain, normal carrying is ensured, and the mechanical arm mechanism for the industrial robot has the advantages of being simple in structure, reasonable in arrangement, low in manufacture cost and the like.

Owner:FOSHAN JIANJINJIAN ELECTRONICS TECH CO LTD

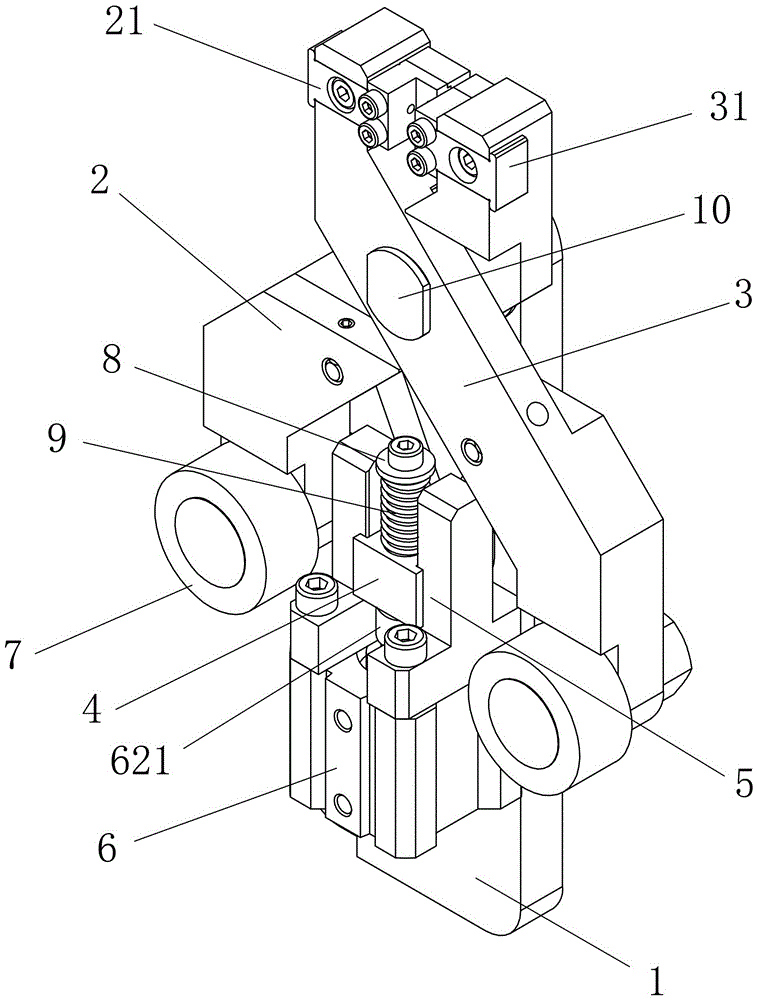

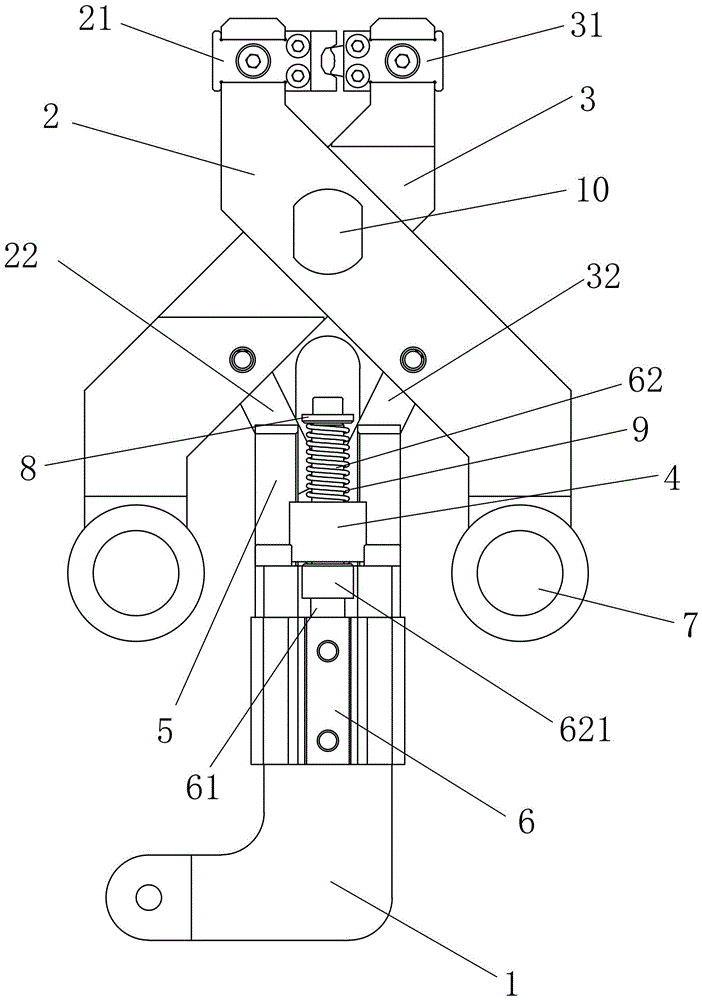

Press-connection mechanism

ActiveCN106785783AAppropriate clamping forceSimple structureLine/current collector detailsEngineeringMechanical engineering

The invention discloses a press-connection mechanism. The press-connection mechanism includes a first press-connection arm and a second press-connection arm, the middle portions of the first press-connection arm and the second press-connection arm are connected with each other through a pivot in a pin-jointed mode, the upper end of the first press-connection arm is provided with a first vice jaw, and the upper end of the second press-connection arm is provided with a second vice jaw. The mechanism is characterized in that the position located between the tail end and a middle pin-jointed point of the first press-connection arm is connected with a first connection rod in a pin-jointed mode, the position located between the tail end and a middle pin-jointed point of the second press-connection arm is connected with a second connection rod in a pin-jointed mode, and one tail end of the first connection rod and one tail end of the second connection rod are connected with one sliding block in a pin-jointed mode; the sliding block is connected with a sliding groove in a sliding mode, a power device is fixed on the sliding groove and used for driving the sliding block to slide on the sliding groove, and the lower end of the first press-connection arm and the lower end of the second press-connection arm are externally connected with press-connection power. According to the press-connection mechanism, a wiring harness can automatically be in press connection with a terminal, no manual operation is needed, the structure is simple, and the press-connection mechanism is convenient to use and can be used in automatic equipment.

Owner:XIAMEN HIPRECISE TECH CO LTD

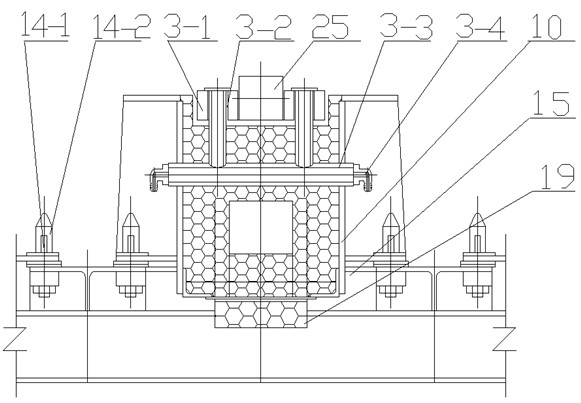

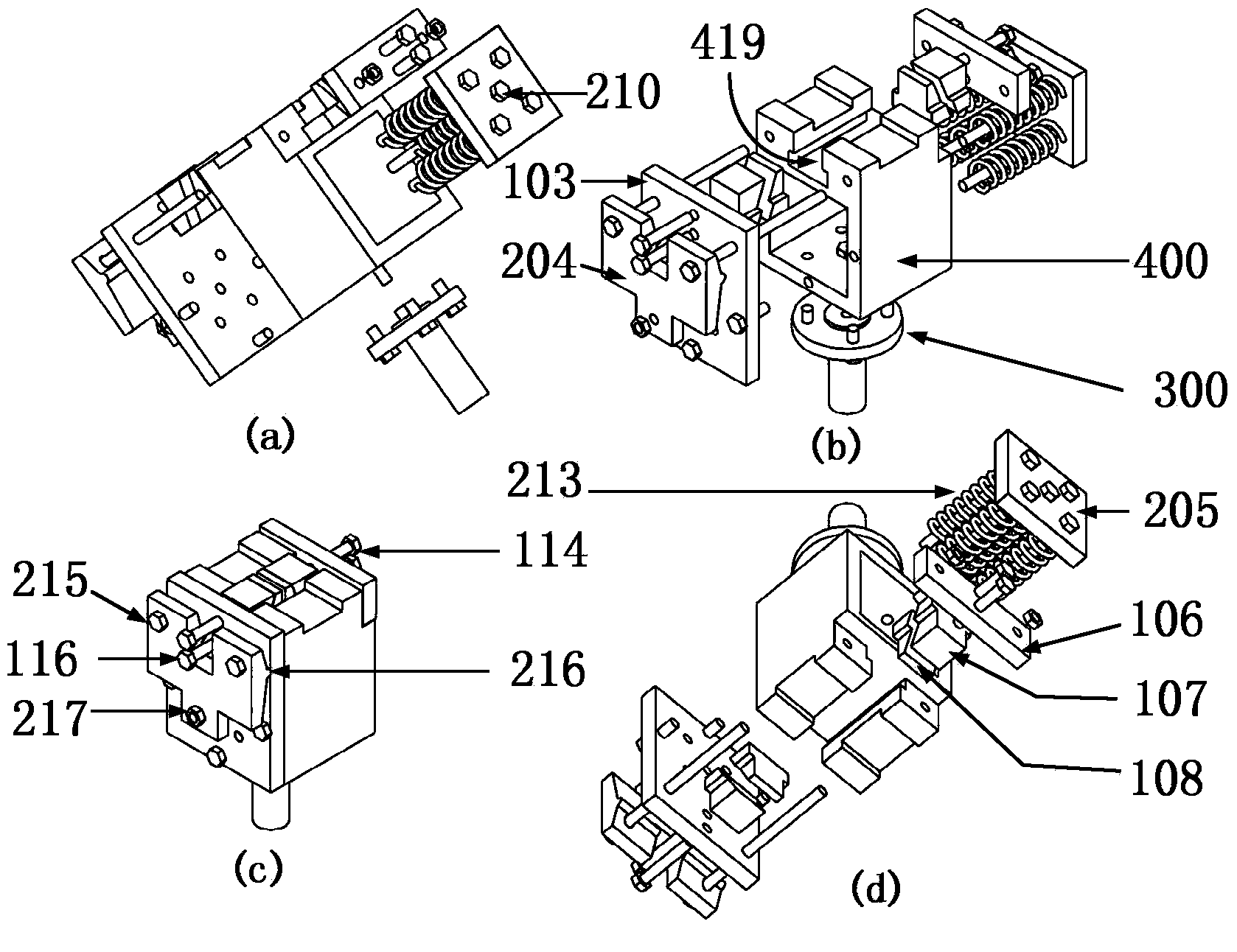

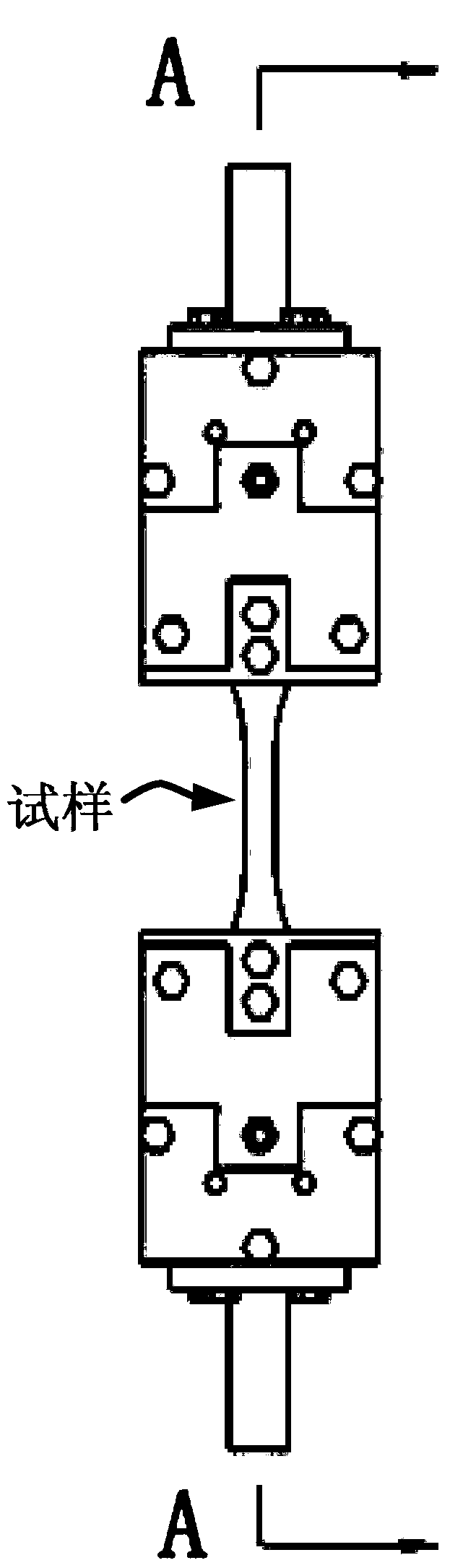

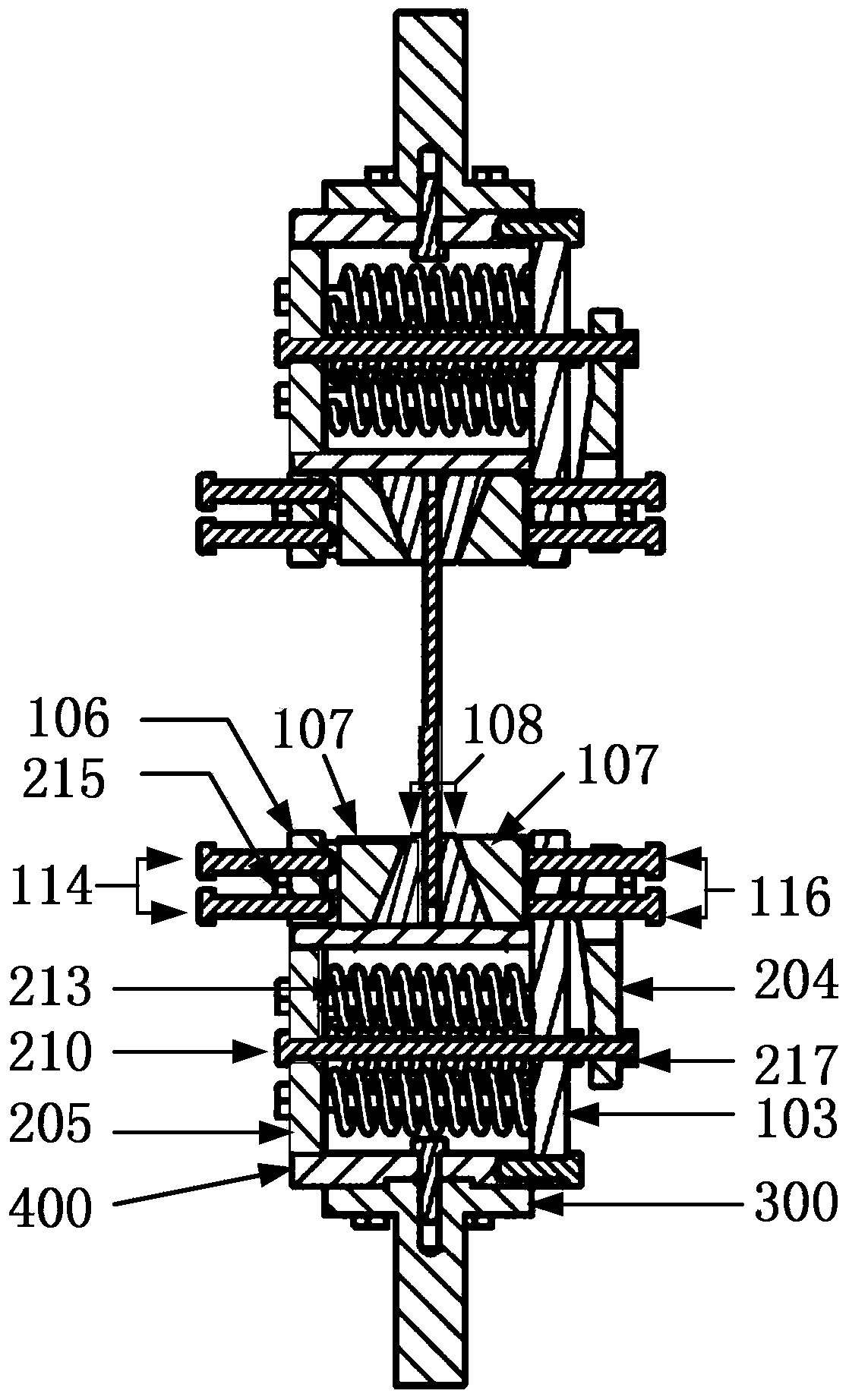

Multifunctional material test clamp based on lever principle

The invention relates to a multifunctional material test clamp based on a lever principle. The multifunctional material test clamp comprises a main box (400), a sample clamping mechanism (100), a clamping force adjustment mechanism (200) and a switching flange (300), wherein the sample clamping mechanism (100) and the clamping force adjustment mechanism (200) are arranged on two inner sides of the main box (400) separately; the switching flange (300) is connected to the main box to be linked with a main shaft of a tester; the clamping force adjustment mechanism transfers force on a spring to a clamping block through a lever warping plate (204). The multifunctional material test clamp can be used for discriminating the magnitude of clamping force, is suitable for clamping of different types of materials by virtue of an enough clamping force adjusting range, and can be conveniently used in a warm humid environment box. The clamping force of the test clamp cannot be quickly decreased due to micro-deformation of a sample, and thus the phenomenon of slippage of the sample in the test process can be effectively prevented. The multifunctional material test clamp is applied to different types of samples, is used for single-axis or multi-axis pulling-pressing circulation tests, torsion tests and relaxation tests, and has the advantages of simple structure, complete functions, convenience in processing, economy, practicality and the like.

Owner:SOUTHWEST JIAOTONG UNIV

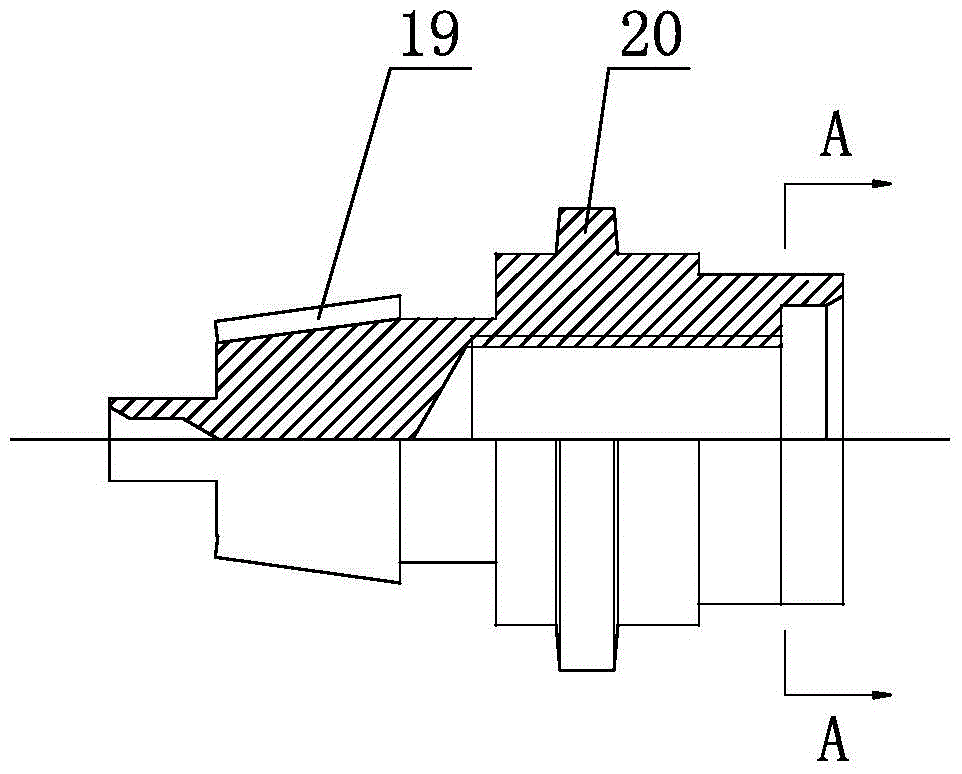

Drill chuck

ActiveUS20150209871A1Appropriate clamping forceEasy to openSleeve/socket jointsChucksEngineeringDrill

The present invention provides a new drill chuck that resolves the problem that the excessive clamping force of the existing drill chuck makes it inconvenient to open the drill chuck and easily damages the cutters. The new drill chuck comprises a front-body, an after-body, and clamping jaws, wherein a thread is provided on the clamping jaw, the after-body is provided with master gears, slave gears are provided between the clamping jaws and the after-body, the master gear fits with the slave gear, a thread is provided inside the slave gear, and the thread of the slave gear fits with the thread of the clamping jaw.

Owner:WEIHAI DAWANG MECHANICAL TECH LTD

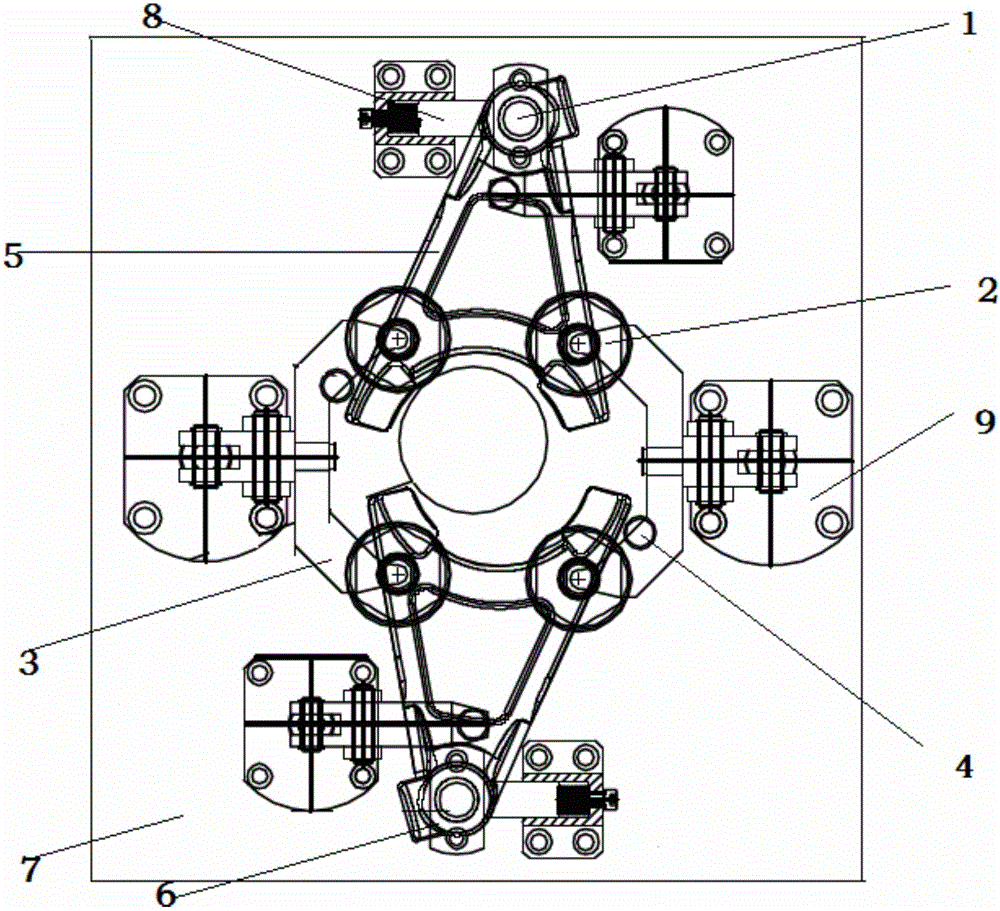

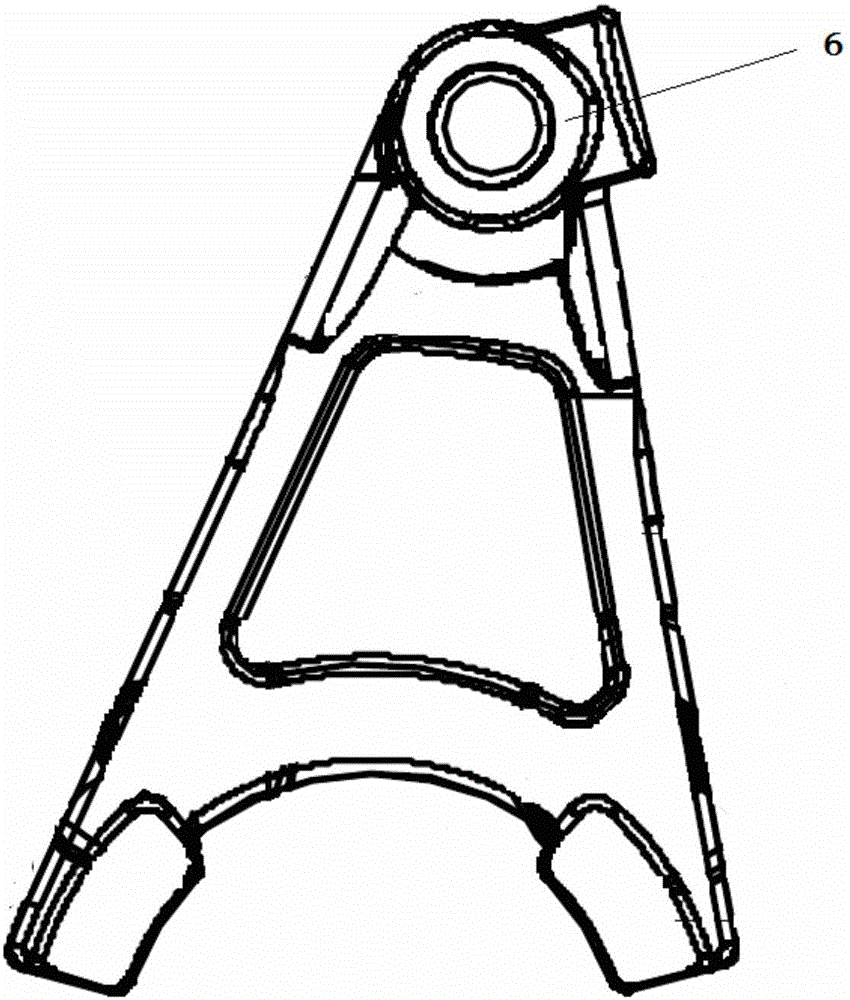

Positioning and clamping device for milling plane on shifting fork

InactiveCN106584152APrecise positioningAppropriate clamping forceMeasurement/indication equipmentsPositioning apparatusEngineeringHigh stress

The invention relates to the field of casting processing of shifting forks and discloses a positioning and clamping device for milling a plane on a shifting fork. The positioning and clamping device comprises a substrate, a clamping mechanism, a controller and a pressure sensor. The shifting fork is an A-shaped workpiece with a positioning hole formed at the pointed end and is arranged on a positioning pin through the positioning hole in a sleeving manner, and the two support legs of the A-shaped workpiece are erected on a support table. The clamping mechanism can prop and press the tops of the support legs in the vertical direction. The pressure sensor is arranged on the support table, and the controller is connected with the clamping mechanism and the pressure sensor. The pressure sensor can acquire a pressure signal born by the support legs and transmit the pressure signal to the controller, and the controller can control the clamping mechanism to start or stop according to the threshold value of the pressure signal. The positioning and clamping device is accurate in positioning and appropriate in clamping force, and therefore, guarantees that the shifting fork can neither displace when clamped nor be unqualified due to breakage caused by excessively high stress.

Owner:安徽凯宇机械制造有限公司

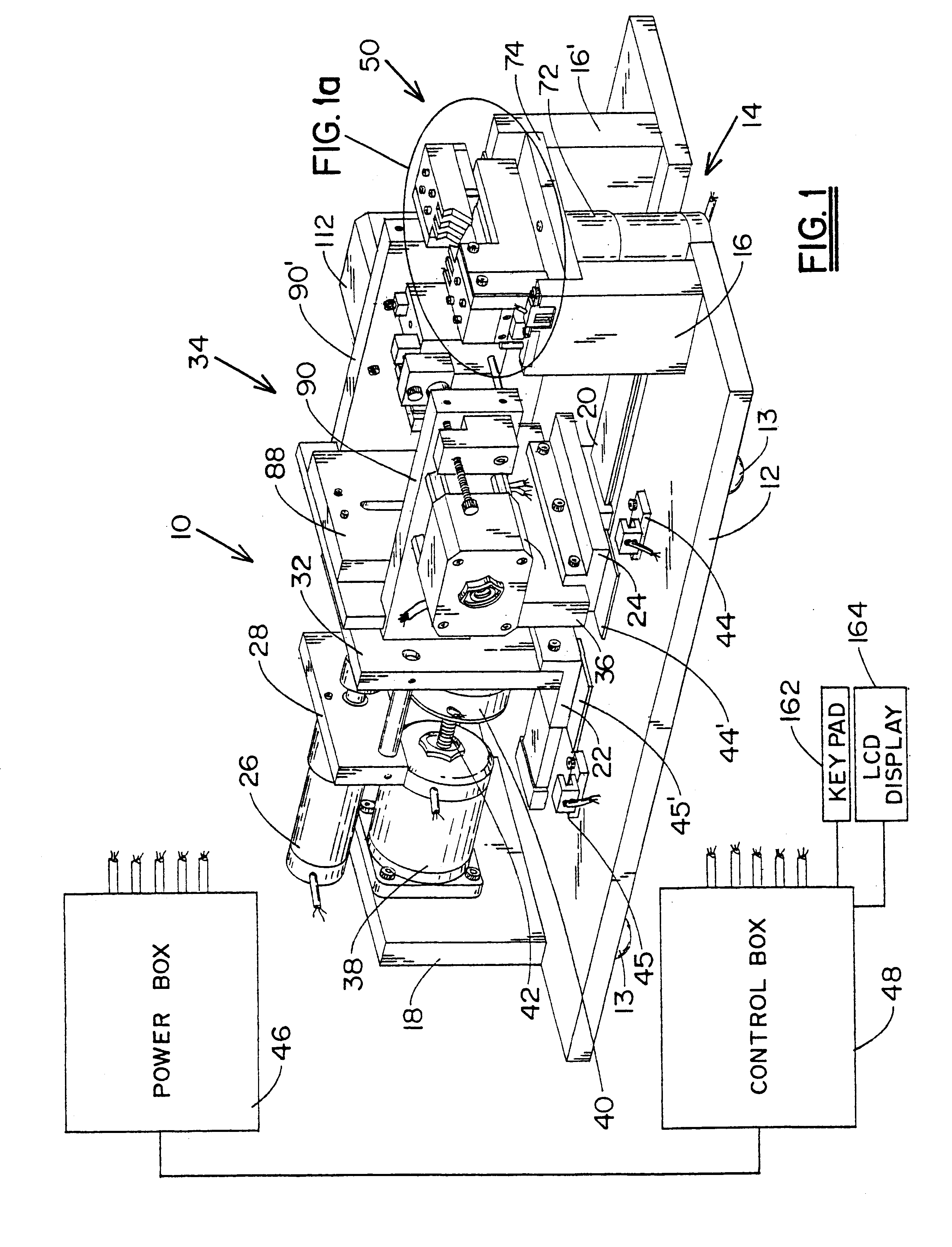

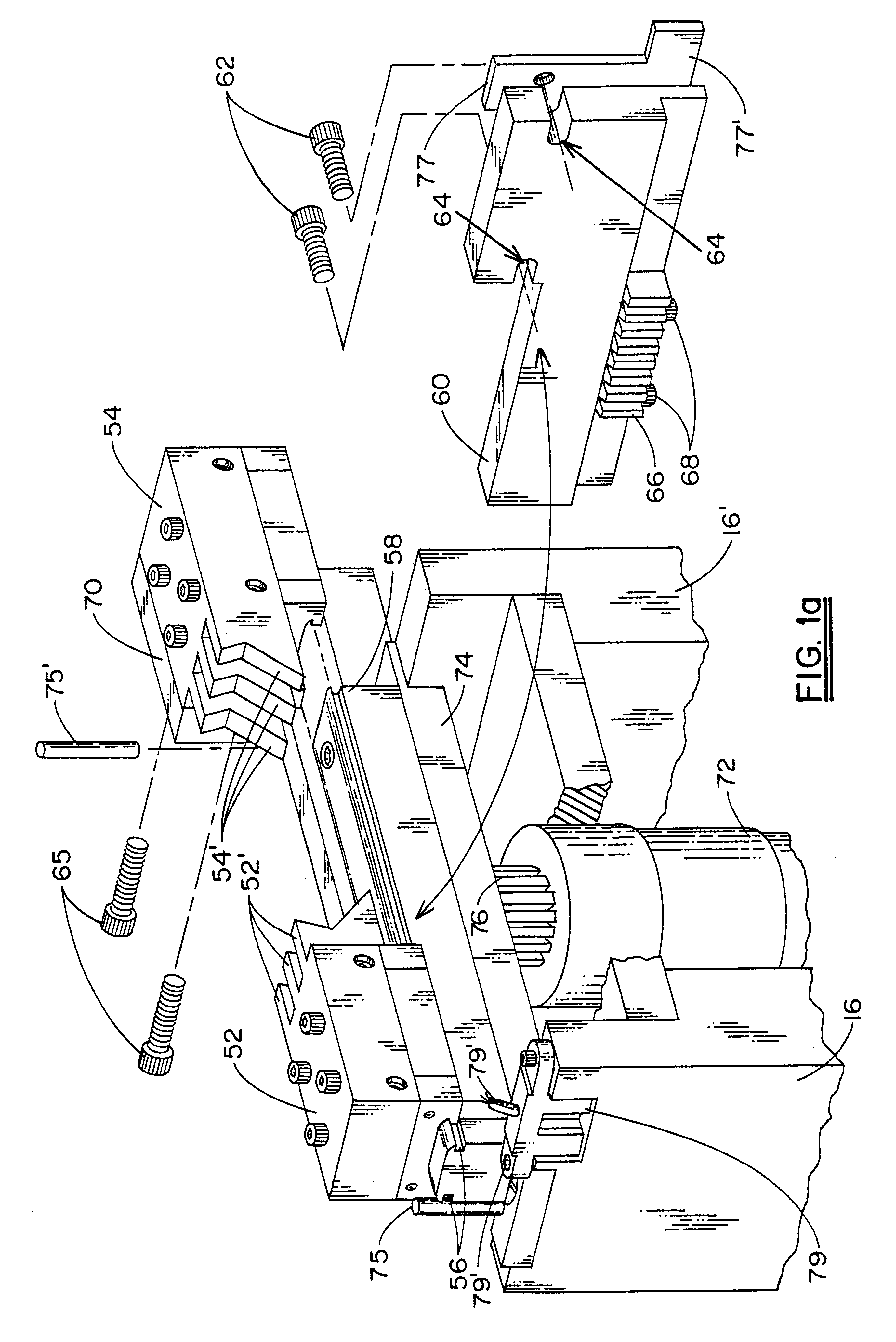

Orbiting blade coaxial cable cutter/stripper

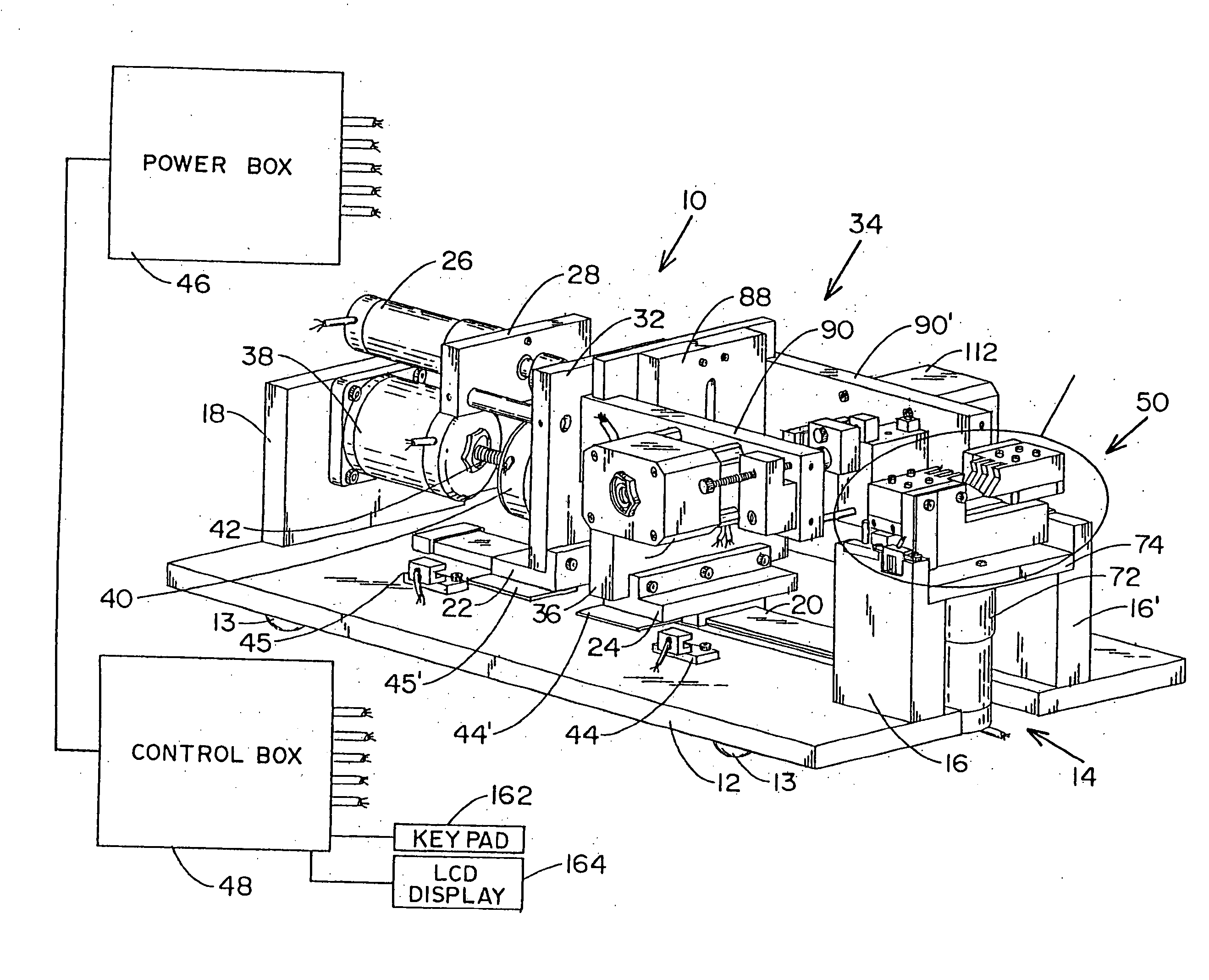

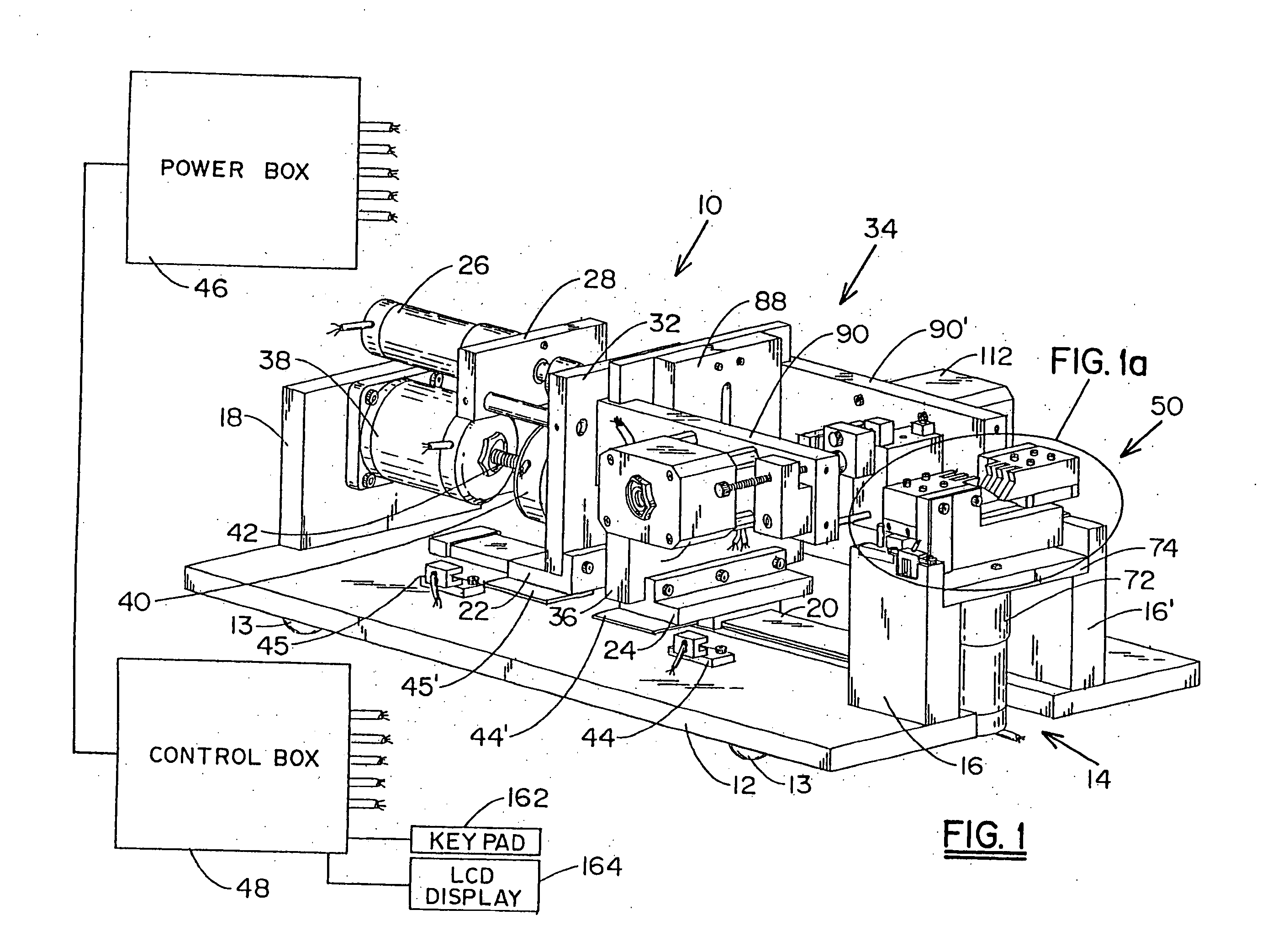

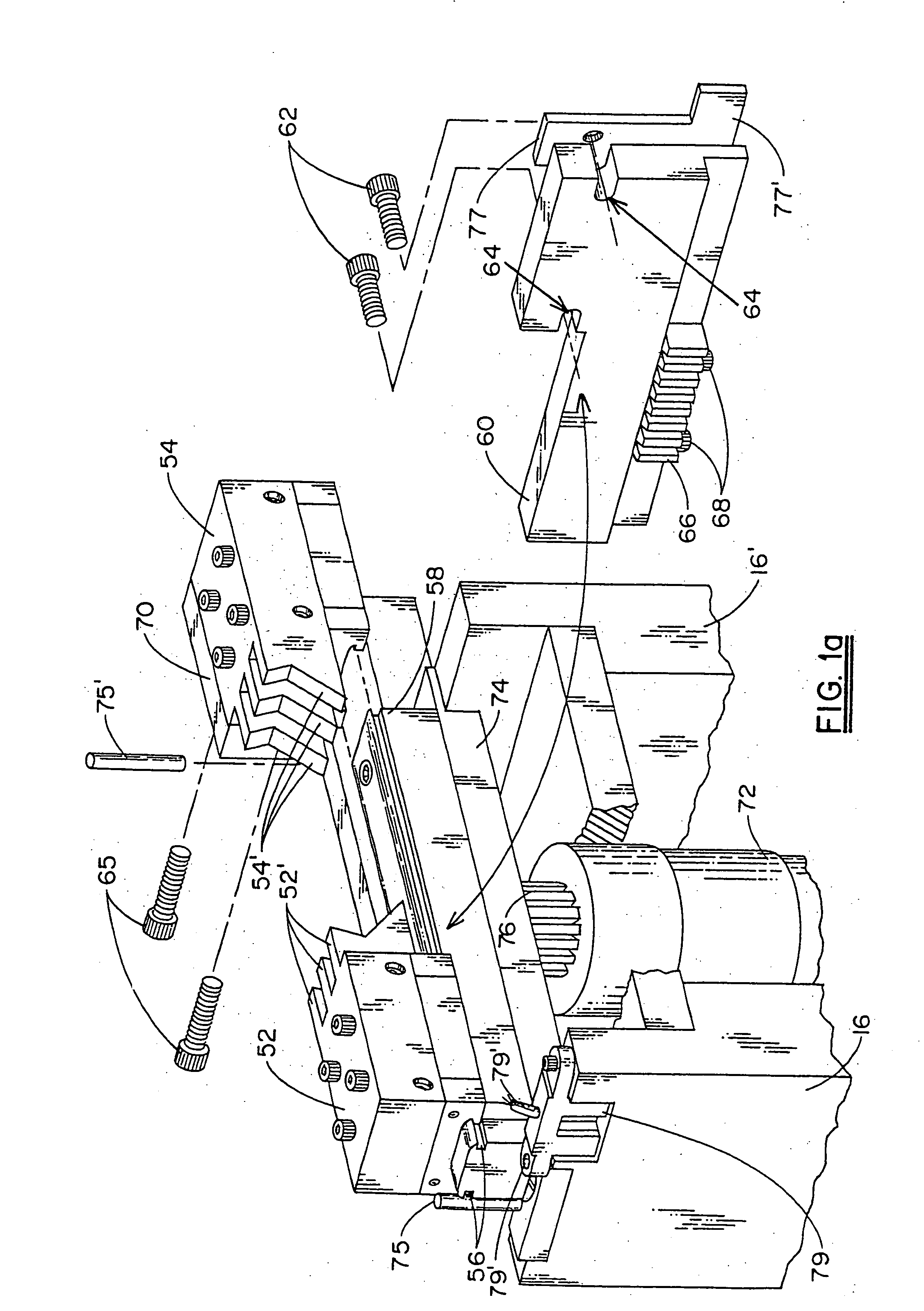

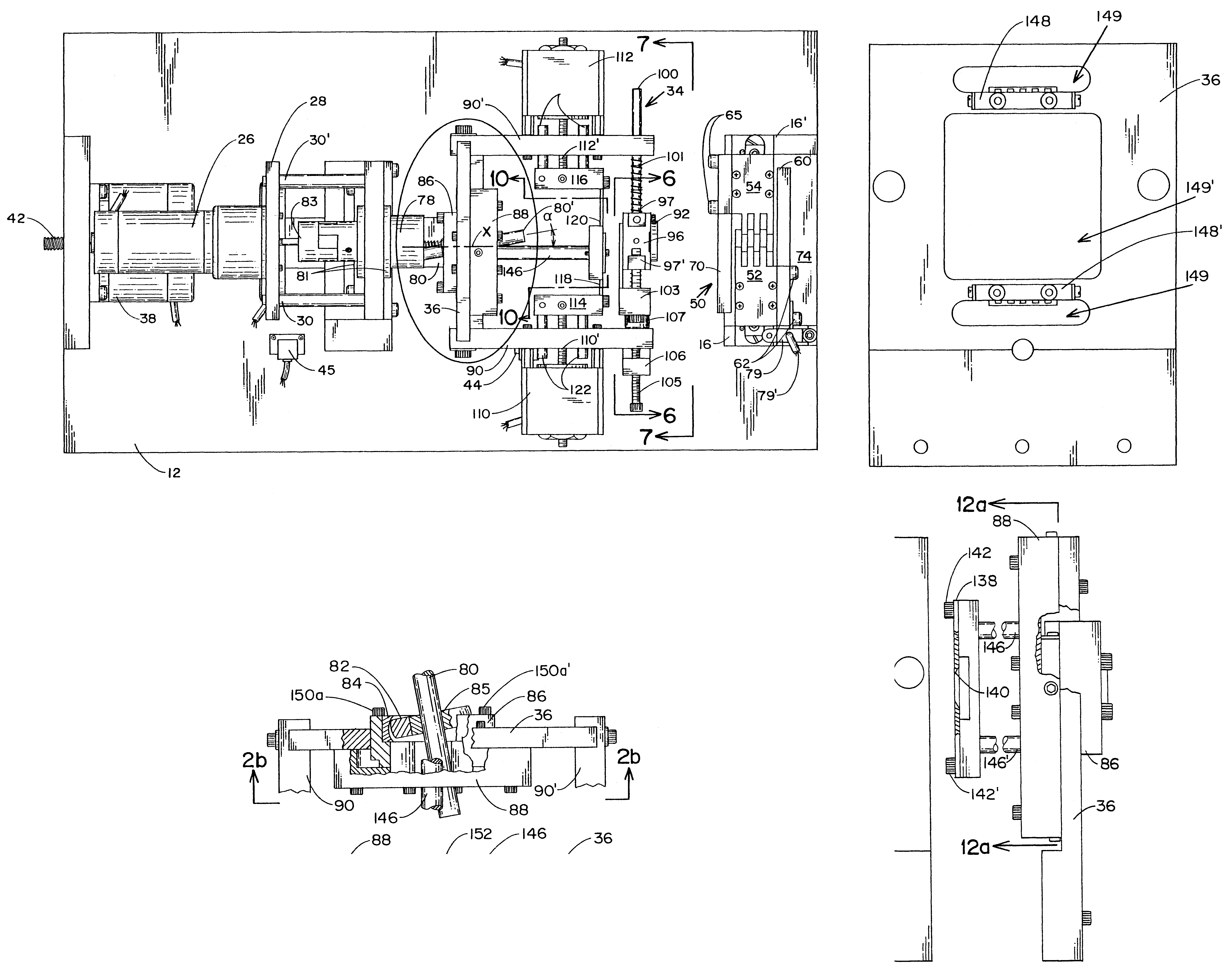

InactiveUS20050034308A1Reliable and simple mechanical arrangementIncrease clamping forceMetal working apparatusApparatus for removing/armouring cablesSpherical bearingElectrical conductor

Apparatus for supporting a coaxial cable, or the like, and effecting cutting and stripping operations to remove a portion of one or more layers which concentrically cover a central conductor. A single blade, having a circular cutting edge, is moved in an orbital path about the cable with rotary motion of a motor translated to orbital motion of the blade through a plurality of plates relatively movable on crossed, linear, roller bearings and a shaft eccentrically affixed to the motor with the shaft and motor axes at an acute angle to one another. The shaft extends through a spherical bearing mounted in one of the plates, thereby translating nutational motion of the shaft to orbiting motion of the plate which is directly attached to the blade. A unique clamping assembly includes a pair of jaws having respective gear racks engaging a single pinion gear on a motor output shaft for linear movement of the jaws by equal distances in opposite directions. A microprocessor controls the level of current to the motor, thereby adjusting the clamping force applied to the cable, and increases this force during the stripping operation, when maximum axial force is applied to the cable. A guide bushing establishes the radial position of the cable axis and is stationary during blade movement, thereby permitting the opening in the bushing to closely approximate the cable diameter. The position of the bushing is adjustable to align the central axis of the bushing opening with that of the blade cutting edge. The bushing is also movable to an inoperative position to permit unobstructed access to the blade for replacement thereof. A pair of gripping members are movable to engage the severed portion of the covering layer to assist in the stripping operation, and a unique combination of hardware and software is provided for calibrating the position of the gripping members at equal distances from the axis of the cable.

Owner:PALMOWSKI DAVID J

Orbiting blade coaxial cable cutter/stripper

InactiveUS6840147B2Improves stripping functionReliable and simple mechanical arrangementMetal working apparatusApparatus for removing/armouring cablesElectrical conductorCoaxial cable

Apparatus for supporting a coaxial cable, or the like, and effecting cutting and stripping operations to remove a portion of one or more layers which concentrically cover a central conductor. A single blade, having a circular cutting edge, is moved in an orbital path about the cable with rotary motion of a motor translated to orbital motion of the blade through a plurality of plates relatively movable on crossed, linear, roller bearings and a shaft eccentrically affixed to the motor with the shaft and motor axes at an acute angle to one another. The shaft extends through a spherical bearing mounted in one of the plates, thereby translating nutational motion of the shaft to orbiting motion of the plate which is directly attached to the blade. A unique clamping assembly includes a pair of jaws having respective gear racks engaging a single pinion gear on a motor output shaft for linear movement of the jaws by equal distances in opposite directions. A microprocessor controls the level of current to the motor, thereby adjusting the clamping force applied to the cable, and increases this force during the stripping operation, when maximum axial force is applied to the cable. A guide bushing establishes the radial position of the cable axis and is stationary during blade movement, thereby permitting the opening in the bushing to closely approximate the cable diameter. The position of the bushing is adjustable to align the central axis of the bushing opening with that of the blade cutting edge. The bushing is also movable to an inoperative position to permit unobstructed access to the blade for replacement thereof. A pair of gripping members are movable to engage the severed portion of the covering layer to assist in the stripping operation, and a unique combination of hardware and software is provided for calibrating the position of the gripping members at equal distances from the axis of the cable.

Owner:ORBITAL TECH

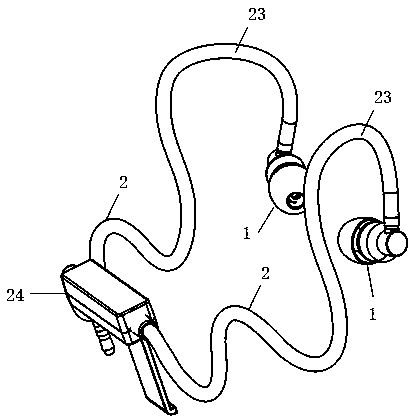

Telescopic back-hung headset

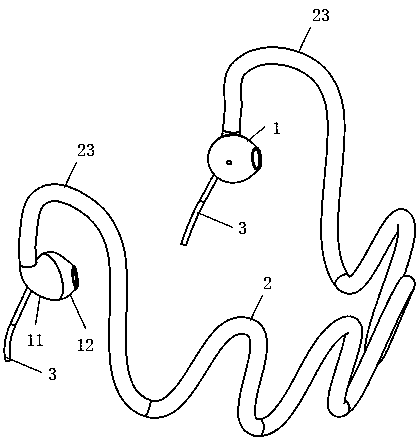

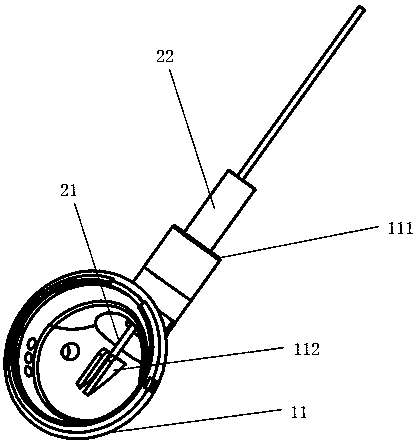

PendingCN107682765AIncrease elasticityImprove scalabilityEarpiece/earphone attachmentsInterference fitAdhesive glue

The invention discloses a telescopic back-hung headset, including left and right headset shells (1) and a headband (2) connecting the left and right headset shells (1). The headband (2) is a wavelikebent pipeline which has moderate elasticity and plasticity and is integrally in a clamping shape, and includes a steel wire inner core (21) and a plastic tube (22) that warps the steel wire inner core(21), and the steel wire inner core (21) is buckled in buckling positions (112) of headset back shells (11) and are adhered with glue; and the plastic tube (22) sleeves tail handles (111) of the headset rear shells (11) in an interference fit mode, and when force applied to the headband (2) exceeds a designed strength, the headset (2) can bend and realize telescopic deformation, thereby changinga clamping radian. According to the headset provided by the invention, the bending radian of the headset headband can e adjusted according to the size of the head of a headset user, and thus the headset can be stably and comfortably fixed at ears of the user even if in a motion process.

Owner:JINMA COMM CO LTD

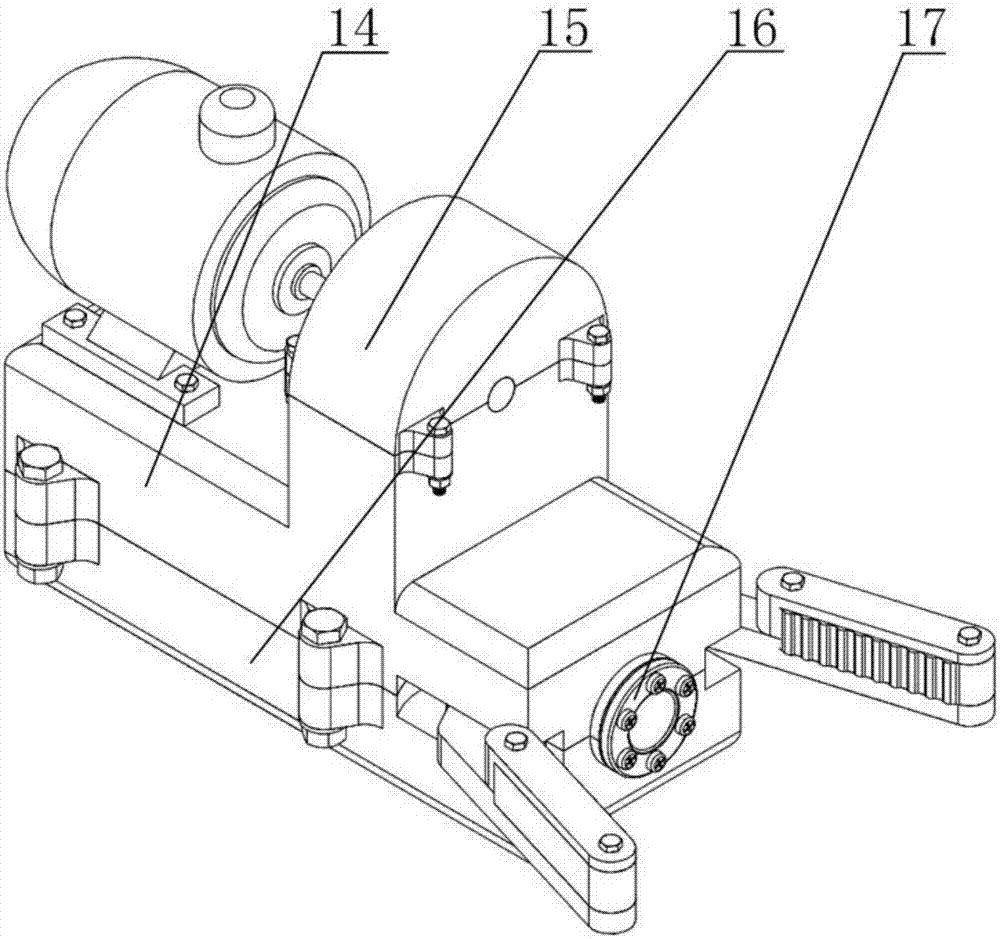

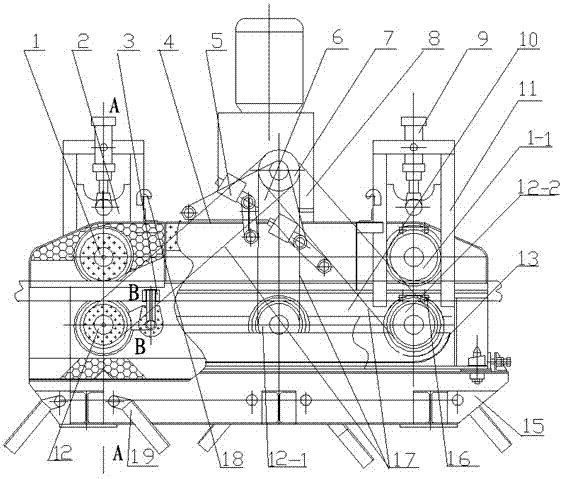

Shock-absorbing clamping device for robot and intelligent box carrying method based on device

The invention relates to a shock-absorbing clamping device for a robot and an intelligent box carrying method based on the clamping device. The clamping device comprises a motor, a transmission device and clamping jaws; the transmission device comprises a worm gear-worm mechanism, a tire coupling and a belt transmission mechanism; the motor is connected with a small belt pulley shaft of the belt transmission mechanism through the tire coupling; a large belt pulley shaft of the belt transmission mechanism and a worm of the worm gear-worm mechanism adopt an integrated structure; the worm drives the two clamping jaws synchronously to act through two symmetrically-arranged worm gears; each clamping jaw and the corresponding worm gear adopt an integrated structure; anti-skid and shock-absorbing pads are arranged on the inner sides of clamping surfaces of the clamping jaws; and by the aid of the structure, the shock-absorbing clamping device has the characteristics of displacement compensation, overload protection, reverse travel self-locking, skid prevention and shock absorbing. Various elastic elements are added in the clamping device to keep the shock-absorbing performance of the clamping device; and meanwhile, the overload protection performance is realized through the belt transmission mechanism, and the function that the robot intelligently selects and carries boxes in different weight is realized on the basis.

Owner:UNIV OF SCI & TECH LIAONING

Adjustable instrument panel center mechanism

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

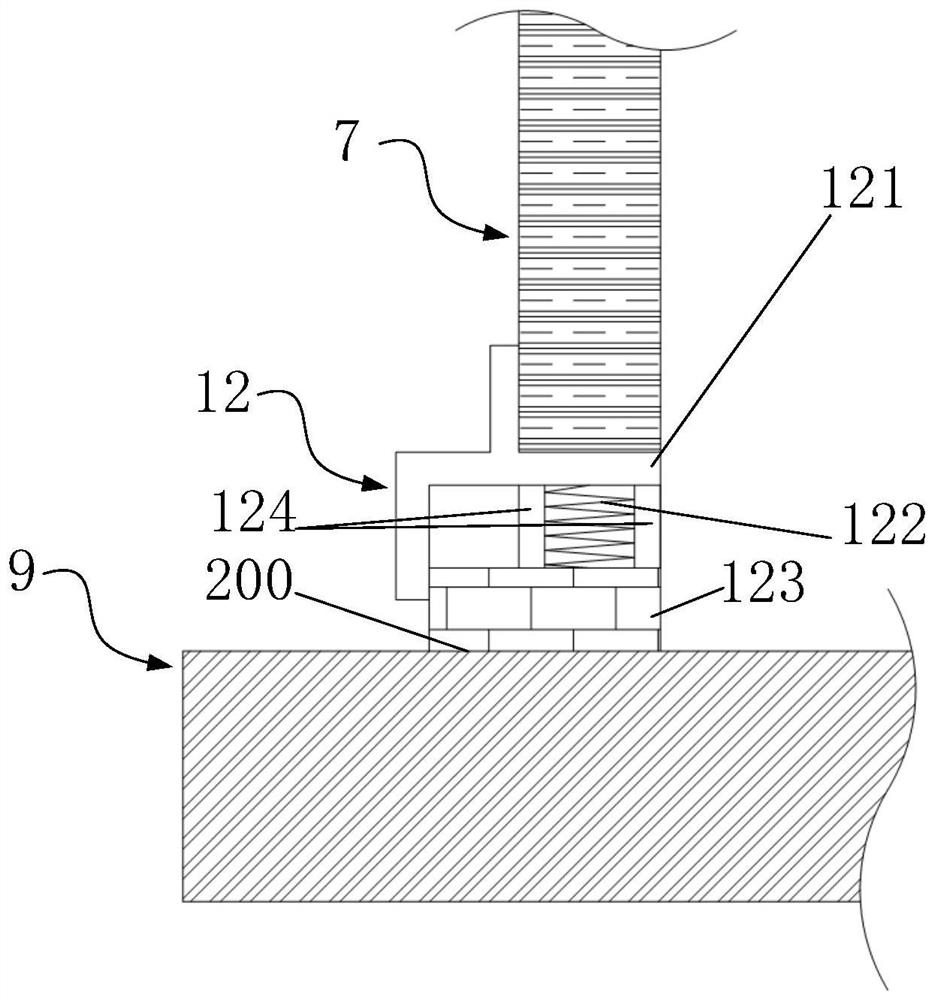

Closed in-column concrete pouring method

ActiveCN111996923AGuaranteed denseSolve the problem of not being able to enter the warehouse from the upper partWithdrawing sample devicesPreparing sample for investigationArchitectural engineeringStructural engineering

The invention discloses a closed in-column concrete pouring method. The concrete pouring method comprises the steps that 1, construction preparation is performed; 2, a pile column formwork is built; 3, pipelines are connected; 4, concrete is poured: step 4.1, a concrete base layer is paved on a construction joint surface of a permanent underpinning beam; 4.2, a concrete solid layer is poured; 4.3,vibration is performed, specifically, a lower-layer attached vibrator and an upper-layer attached vibrator are started in sequence while a concrete solid layer is poured; 5, concrete curing is performed; 6, formwork removal operation is performed; and 7, concrete strength of a pile is measured. According to the closed in-column concrete pouring method, concrete is conveyed into a closed pile column formwork through a ground pump and a pump pipe; and concrete in the pile formwork rolls over from bottom to top to fill the pile formwork under the action of a jacking force till that the pile formwork is filled with the concrete, exhausting of the concrete at the top is achieved through the exhaust pipe in a pouring period, and compactness of the concrete at the top is guaranteed.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

drill chuck

ActiveCN104411432BAvoid problems that are difficult or even impossible to openAppropriate clamping forceSleeve/socket jointsChucksDrillMachining

The present invention provides a drill chuck, which solves the original problem of inconvenient opening and easy damage to the tool due to too much clamping force of the drill chuck. There are threads, the rear body is provided with a driving gear, and a driven gear is provided between the jaws and the rear body, the driving gear and the driven gear cooperate with each other, and the driven gear is provided with threads inside, and the threads cooperate with the threads of the jaws The invention can be widely used in the field of mechanical processing.

Owner:WEIHAI DAWANG HARDWARE PROD

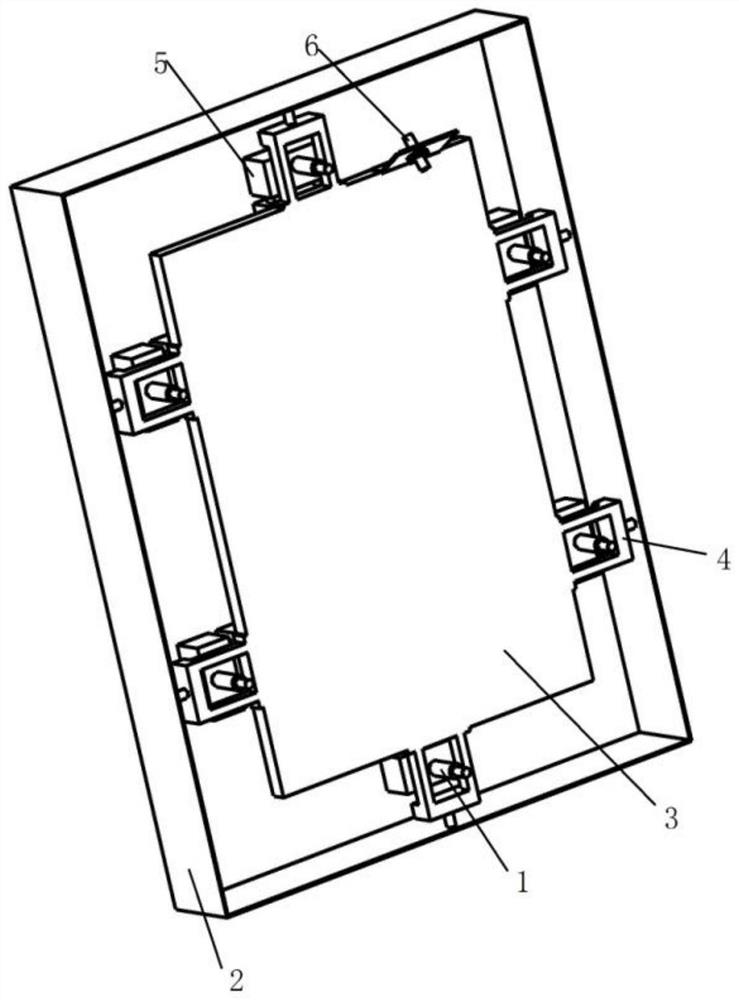

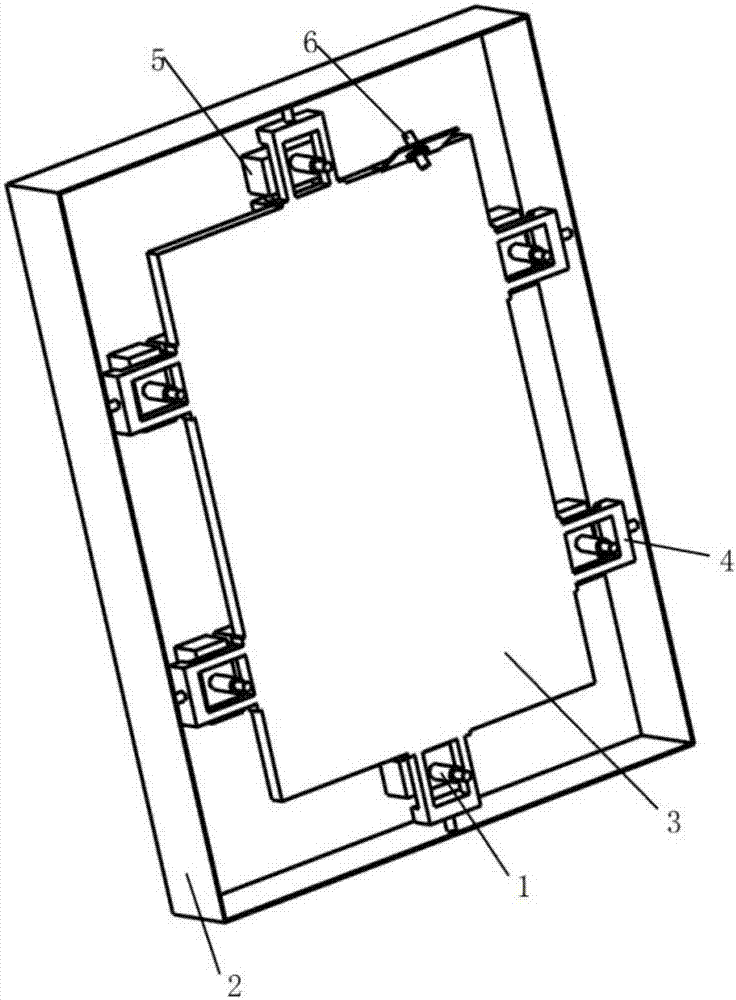

A clamping device for a coated glass clamping manipulator

The invention discloses a fixture device of a film plating glass clamping manipulator. The fixture device comprises multiple clamping clips, a substrate, a support plate and a photoelectric identifying device; the substrate is connected with a mechanical arm of the film plating glass clamping manipulator; the support plate is fixed on the substrate through bolts; the multiple clamping clips are distributed around the support plate, and are positioned between the support plate and the substrate; the photoelectric identifying device is fixed on the side edge of the support plate; the clamping clips comprise clamping hands, clamping hand brackets and pneumatic devices; the pneumatic devices are fixed on the back surface of the support plate; the clamping hands are fixed on the pneumatic devices; clamping and loosening of the clamping hands are realized through driving by the pneumatic devices; and the clamping hands can move in space surrounded by the clamping hand brackets. The fixture device can clamp glass from the side surface without contacting with the surface of the glass, guarantees the surface cleanness of the glass, and is proper in clamping force.

Owner:JILIN UNIV

An electric pinch valve

ActiveCN105508650BAdjustable positionAppropriate clamping forceDiaphragm valvesOperating means/releasing devices for valvesPeritoneal dialysisPinch valve

The invention relates to an electric pinch valve. A stepping motor rotates forwardly and reversely to drive the pinch valve to be opened and closed, so that the pinch valve can loosen or clamp an elastic hose, thereby controlling the on-off state of the fluid in the elastic hose. The electric pinch valve comprises a hose clamp port assembly, a movable valve assembly, a stopping device assembly and a connecting plate (2), wherein the hose clamp port assembly is installed in the central position of the front surface of the connecting plate (2); the movable valve assembly is inserted into a central circular hole (2k) on the back surface of the connecting plate (2) and fixed to the back surface of the connecting plate (2); the stopping device assembly is inserted into an elliptical cavity (2m) on the right side surface of the connecting plate (2); a rotor (4) and a rotor plate (5) of the movable valve assembly are fixed to a motor rotating shaft and rotate coaxially; two microswitches (9, 10) installed on a switch plate (7) in the stopping device assembly are used for judging to clamp or loosen the hose; and the judgment result is used as the reference for stopping the motor. The electric pinch valve is applicable to biological artificial livers, blood cleansing machines, peritoneal dialysis machines and other medical facilities.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

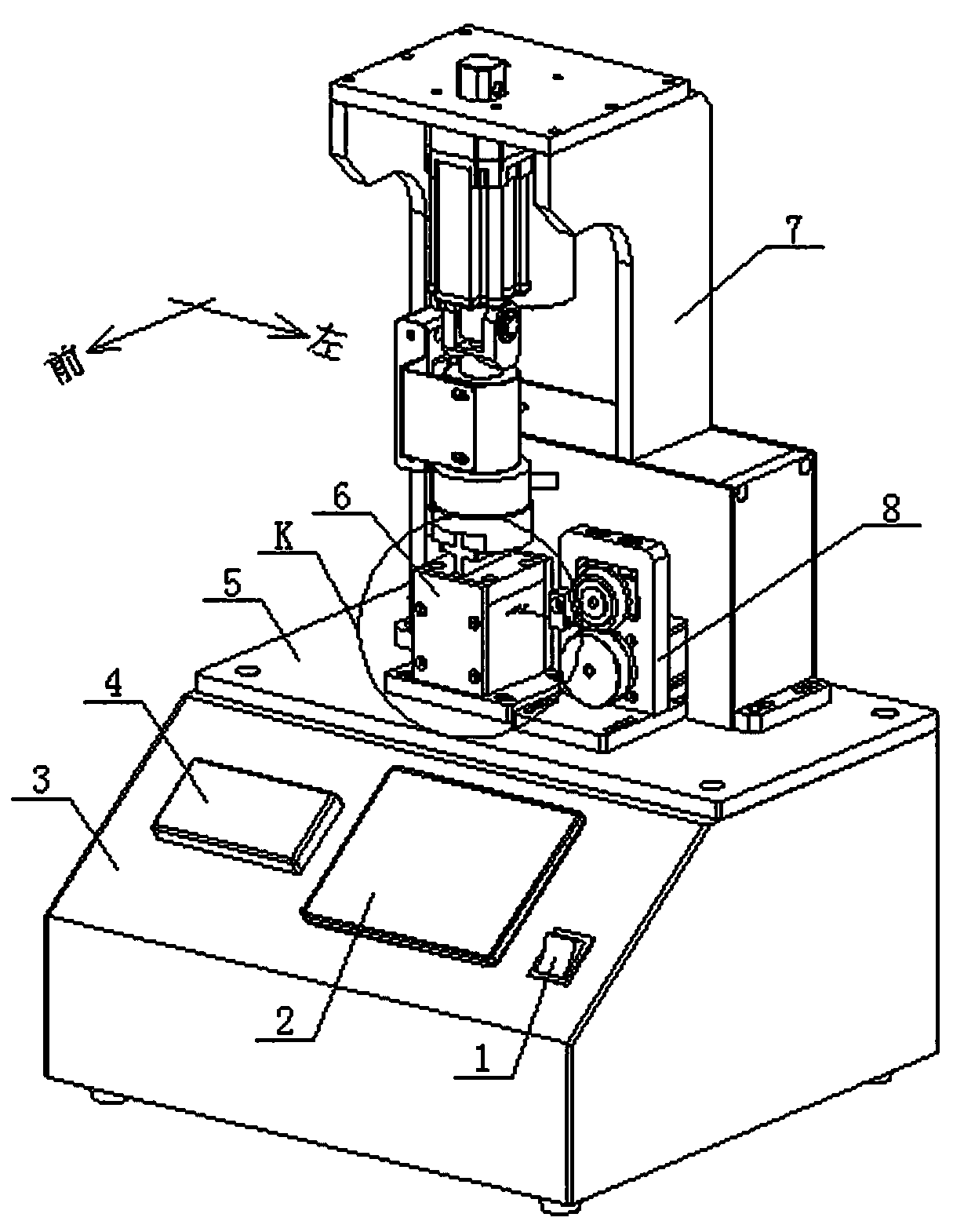

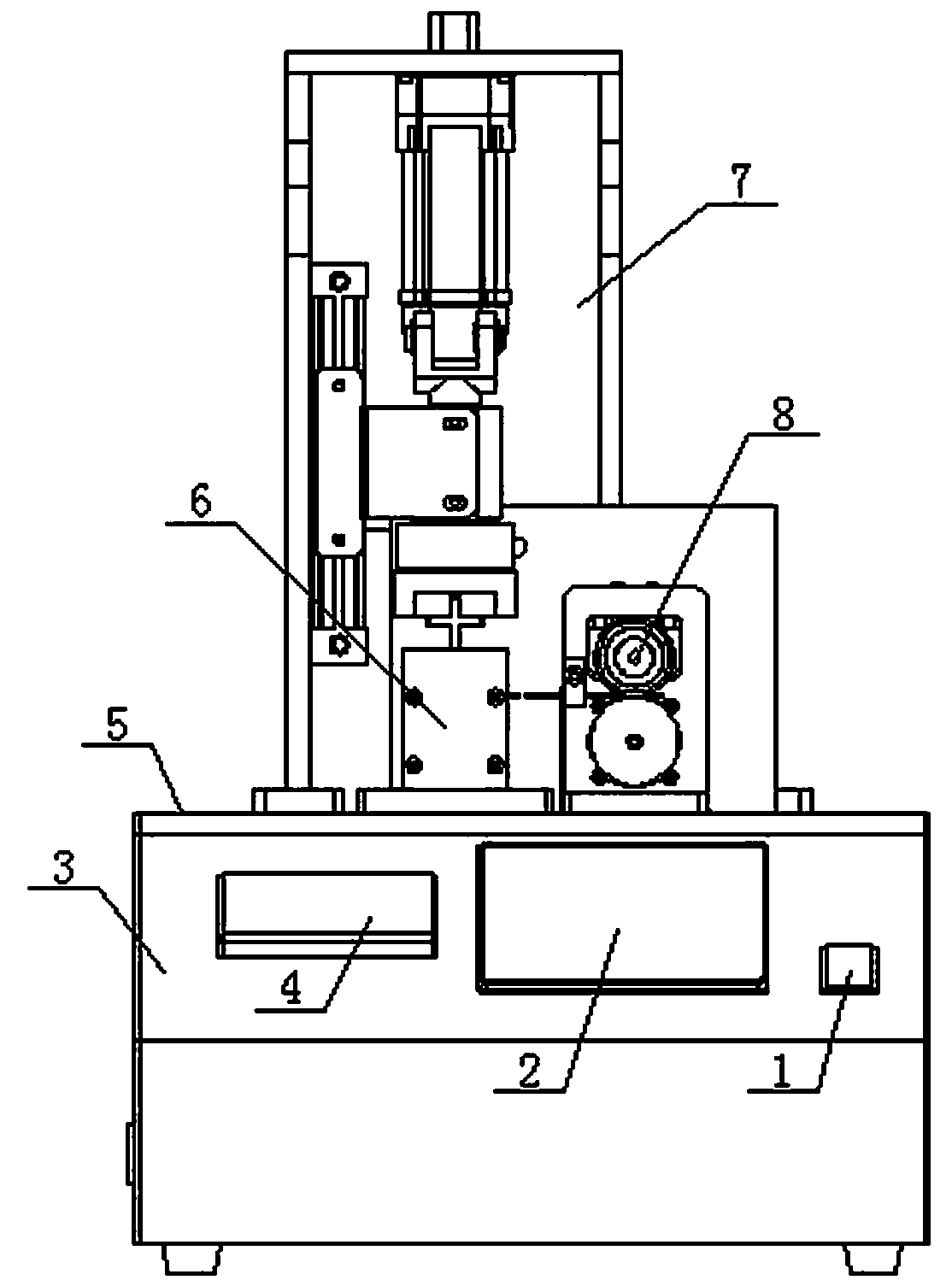

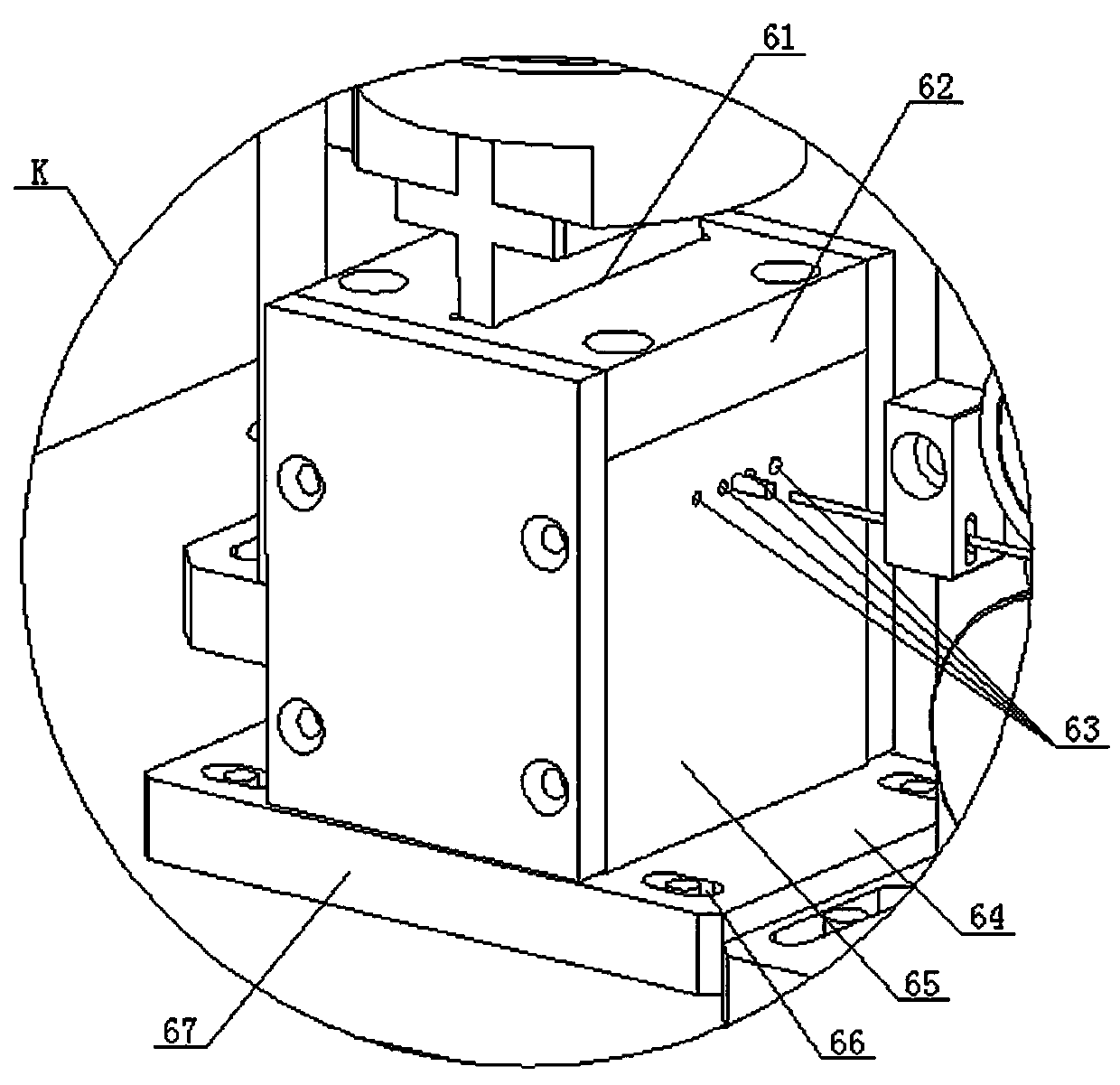

Automatic steel wire shearing force checking device

ActiveCN111413229AMovement Precise ControlPrecise control of shear forceMaterial strength using repeated/pulsating forcesHydraulic cylinderRazor blade steel

The invention discloses an automatic steel wire shearing force checking device, which belongs to the technical field of steel wire detection, measurement and calibration. The device comprises a cabinet; the top of the cabinet is a working platform; a steel wire shearing mechanism, a steel wire supporting mechanism and a steel wire conveying mechanism are installed on the working platform; the steel wire shearing mechanism comprises a supporting frame body fixed to the working platform; a hydraulic cylinder with a piston rod vertically arranged downwards is installed on the supporting frame body; a movable blade is connected to the tail end of the piston rod through a pressure sensor; the steel wire supporting mechanism is located below the movable blade, a fixed blade matched with the movable blade is installed on the steel wire supporting mechanism, and the steel wire conveying mechanism is located on the steel wire input side of the steel wire supporting mechanism. Through the mutualcooperation of the steel wire shearing mechanism, the steel wire supporting mechanism and the steel wire conveying mechanism, the shearing force checking device of the test steel wire for the pliersshearing force test is realized.

Owner:开封市质量技术监督检验测试中心

Fixture device of film plating glass clamping manipulator

The invention discloses a fixture device of a film plating glass clamping manipulator. The fixture device comprises multiple clamping clips, a substrate, a support plate and a photoelectric identifying device; the substrate is connected with a mechanical arm of the film plating glass clamping manipulator; the support plate is fixed on the substrate through bolts; the multiple clamping clips are distributed around the support plate, and are positioned between the support plate and the substrate; the photoelectric identifying device is fixed on the side edge of the support plate; the clamping clips comprise clamping hands, clamping hand brackets and pneumatic devices; the pneumatic devices are fixed on the back surface of the support plate; the clamping hands are fixed on the pneumatic devices; clamping and loosening of the clamping hands are realized through driving by the pneumatic devices; and the clamping hands can move in space surrounded by the clamping hand brackets. The fixture device can clamp glass from the side surface without contacting with the surface of the glass, guarantees the surface cleanness of the glass, and is proper in clamping force.

Owner:JILIN UNIV

Rail vehicle aluminum profile self-positioning polishing tool

ActiveCN113618584APrecise placementAccurate placementGrinding machinesGrinding feedersAutomotive engineeringEngineering

The invention provides a rail vehicle aluminum profile self-positioning polishing tool. The rail vehicle aluminum profile self-positioning polishing tool comprises positioning platforms, supporting platforms and clamping platforms which are used in cooperation. The positioning platforms are installed at the two ends of a rail vehicle aluminum profile and comprise supporting platforms, first positioning devices and second positioning devices; the first positioning devices and the second positioning devices are placed on the supporting platforms; the first positioning devices comprise first self-positioning seats; the second positioning devices comprise second self-positioning seats and clamping devices installed on the side faces of the second self-positioning seats, and the second self-positioning seats are inserted into the first self-positioning seats; the supporting platforms are installed at the bottom of the rail vehicle aluminum profile; and the clamping platforms are installed at the bottom of the rail vehicle aluminum profile, and a clamping device used for clamping the vehicle aluminum profile is arranged on one side of each clamping platform.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A self-positioning grinding tool for aluminum profiles of rail vehicles

ActiveCN113618584BAccurate placementEasy to installGrinding machinesGrinding feedersThermodynamicsMechanical engineering

The invention provides a self-positioning grinding tool for an aluminum profile of a rail vehicle, including a positioning platform, a supporting platform and a clamping platform used in conjunction; The first positioning device and the second positioning device on the device; the first positioning device includes a first self-positioning seat; the second positioning device includes a second self-positioning seat and a clamping device installed on the side of the second self-positioning seat, The second self-positioning seat is inserted into the first self-positioning seat; the supporting platform is installed on the bottom of the aluminum profile of the rail vehicle; the clamping platform is installed on the bottom of the aluminum profile of the rail vehicle, on one side of the clamping platform There is a clamping device for clamping the aluminum profile of the vehicle.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Intermittent wire feeding device

PendingCN112719158ASolve problems such as clamping damage and difficulty in installation and debuggingGuaranteed tensionWire rodElectric machine

The invention discloses an intermittent wire feeding device which comprises a cam (1), a main shaft (2), a rack (3), a wire passing groove (4), a dragging and clamping assembly (5), a motor (6) and the like. An adjustable mechanism is additionally arranged, an air cylinder is selected to serve as a driving element of a clamping mechanism, the size of a driving force arm is designed reasonably, thus enough driving torque is ensured, and the contour of the wire passing groove (4) is designed to be in an S arc shape. The device overcomes the following defects of similar equipment in the market at present that the wire feeding length cannot be adjusted accurately in time according to the production requirement, due to wire moving, the cut length is not uniform, due to insufficient dragging force, the equipment gets stuck, due to too small clamping force, sliding occurs, the cut length is too short, due to too large clamping force, wires are damaged by clamping, and installing and debugging are difficult.

Owner:ANHUI UNIV OF SCI & TECH

Instrument panel positioning fixture

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

Underdrive-concentrated withdrawal and straightening machine with thermal insulation device

The invention provides an underdrive-concentrated withdrawal and straightening machine with a thermal insulation device, which comprises a driving device and is characterized in that a first driving roller, a second driving roller and a third driving roller are arranged on a withdrawal and straightening machine base lined with refractory castables, a first driven roller and a second driven rollerare respectively arranged above the first driving roller and the third driving roller and are driven to do lifting movement in a lifting guide cover device to ensure that the first driving roller together with the first driven roller and the third driving roller together with the second driven roller to clamp and deliver steel billets to move and to be straightened. The invention has the advantages of realizing and improving the working conditions and the surrounding environment of the withdrawal and straightening machine, reducing water energy consumption, preventing excessive heat dissipation and realizing high degree of sealing in the whole process of heat transferring in order to achieve the purposes of decreasing the heat dissipation of a hot billet, improving charging temperature, reducing energy consumption and steel consumption and improving product quality and provide conditions for the hot charging and hot conveying of some steel types in a protective atmosphere and the direct rolling of the steel billet.

Owner:何学才

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com