Instrument panel positioning fixture

A technology for positioning fixtures and instrument panels, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of large clamping force, inconvenient operation for workers, and too loose clamping force, so as to improve work efficiency and make adjustments convenient and fast , the effect of meeting the braking requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

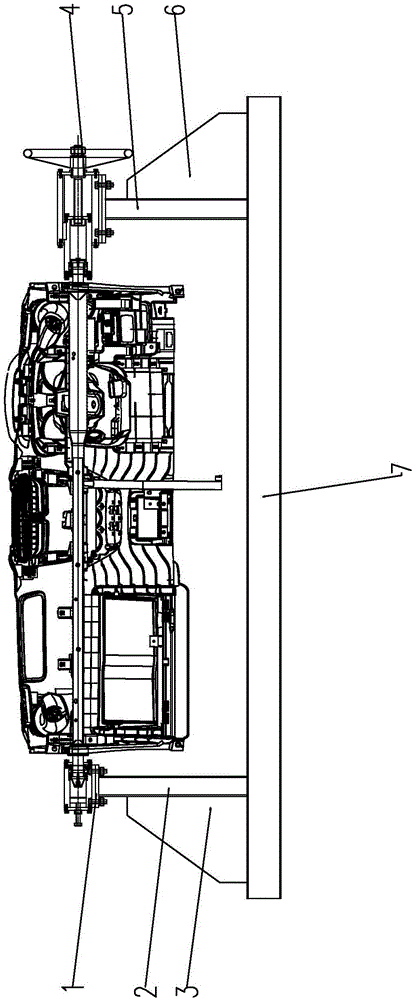

[0020] like figure 1 As shown, the present invention mainly includes a fixed top 1, a fixed top support seat 2, an adjustable top 4, an adjustable top support seat 5 and a base 7, and the left and right ends of the base 7 are respectively fixed with a fixed top support seat 2 and an adjustable top support Seat 5, the upper end of the fixed top support seat 2 is connected by bolts to fix the top 1, and the upper end of the adjustable top support seat 5 is connected by bolts to adjust the top 4.

[0021] A fixed top support seat reinforcement plate 3 is provided between the fixed top support seat 2 and the base 7 , and an adjustable top support seat reinforcement plate 6 is provided between the adjustable top support seat 5 and the base 7 .

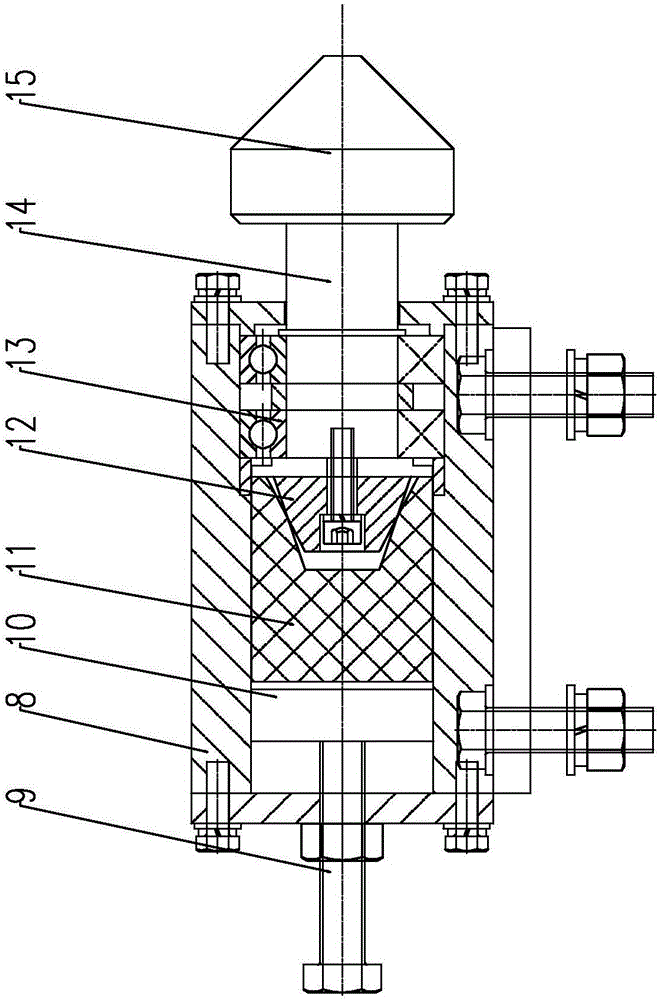

[0022] like figure 2 As shown, the fixed top 1 includes a fixed top seat 8, and a damping block 11 is slidably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com