drill chuck

一种钻夹头、夹爪的技术,应用在机械加工用刀具的夹具领域,能够解决易过大破坏刀具、钻夹头不方便打开等问题,达到避免费劲甚至打不开的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

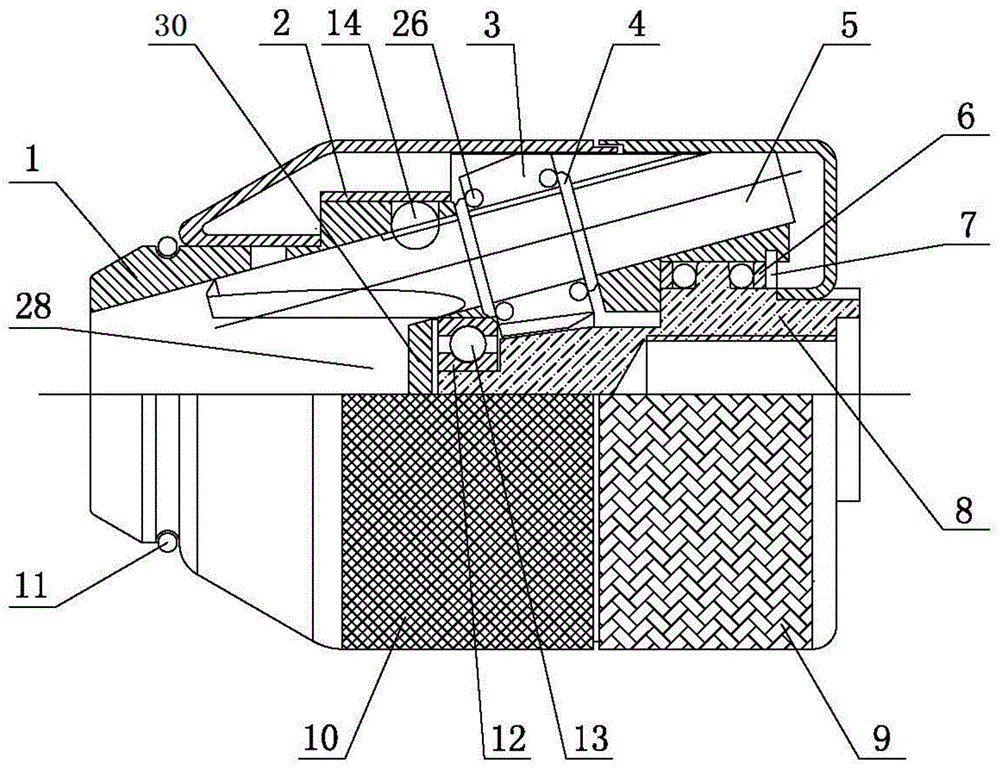

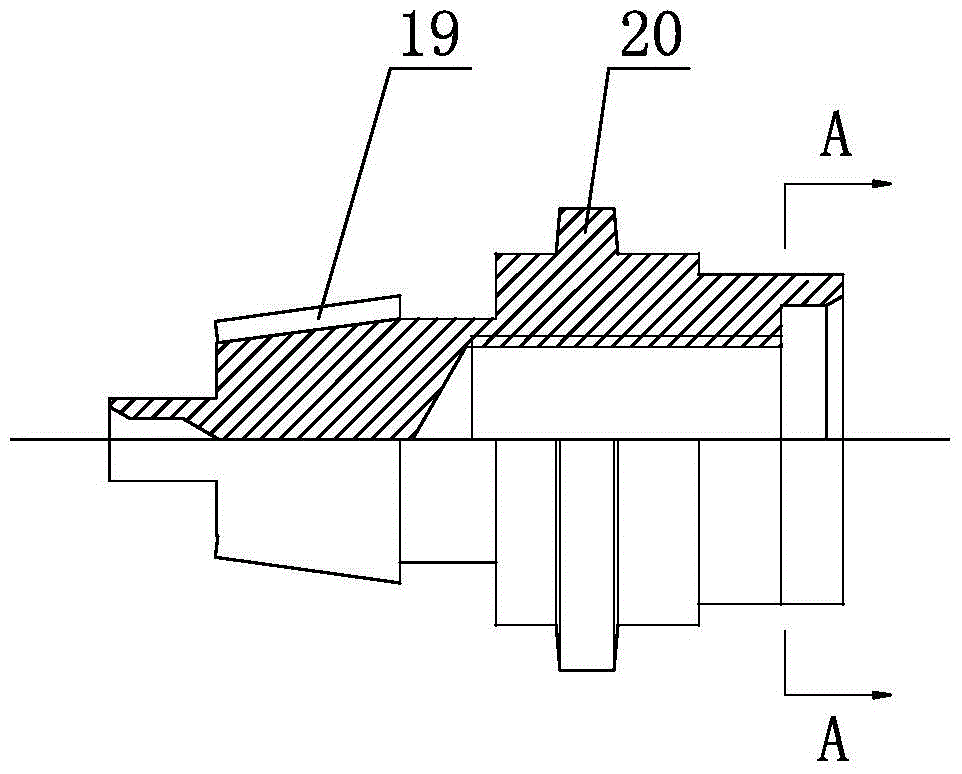

[0026] Such as figure 1 As shown, the present invention mainly includes a front body 1, a rear body 8, a front cover 10, a rear cover 9, jaws 5, and a driven gear 3. The rear body 8 is built in the front body 1 and can only rotate laterally relative to the front body 1 . The front body 1 is provided with a jaw hole 15 , and the jaw 5 is located in the jaw hole 15 . The driven gear 3 is provided with an internal thread, which cooperates with the outer peripheral thread of the jaw 5. The lower end of the rear body 8 is provided with a driving gear 19, and the driving gear 19 cooperates with the driven gear 3. When the rear body 8 rotates , the driven gear 3 also rotates, and the jaw 5 moves up and down driven by the gear 3 .

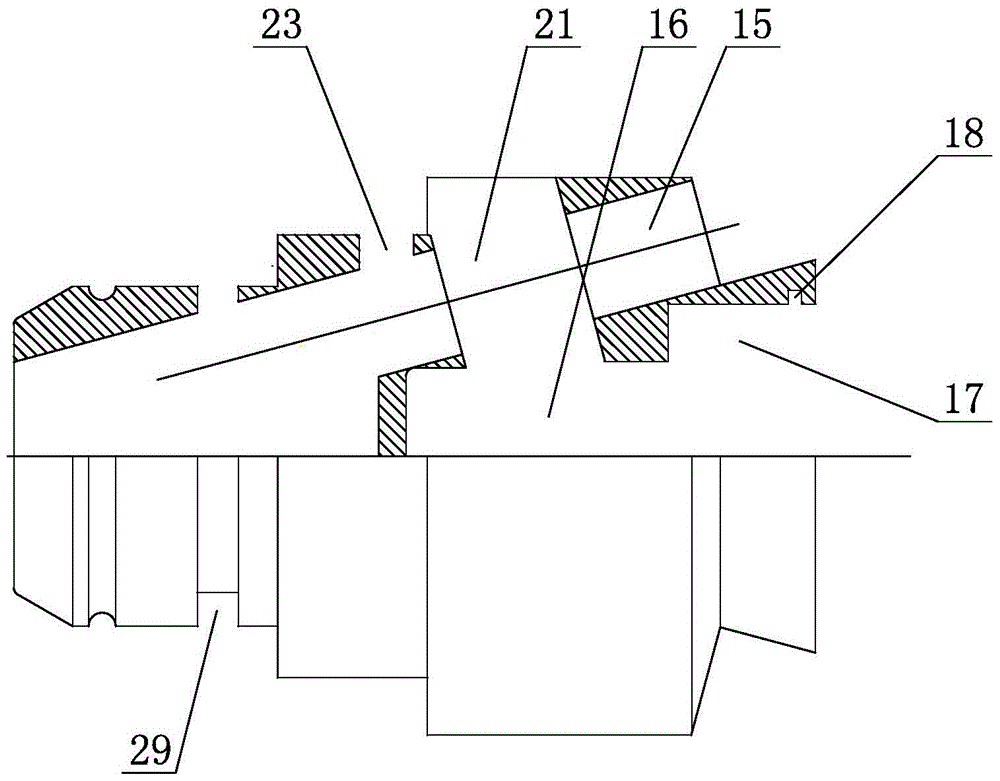

[0027] Such as Figure 2 to Figure 4 As shown, a front groove 16 and a rear groove 17 are provided at the center of the rear end of the front body 1 , and when the rear body 8 is inserted into the front body 1 , the rear body 8 just fits with these two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com