Underdrive-concentrated withdrawal and straightening machine with thermal insulation device

A technology of a heat preservation device and a tension leveler, which is applied in the field of a centralized lower transmission progressive tension leveler, can solve problems such as large floor space, and achieve the effects of high heating efficiency in the furnace, easy maintenance, and reduced consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

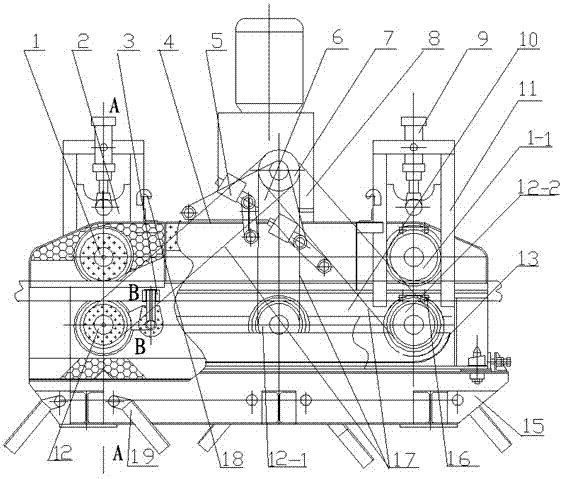

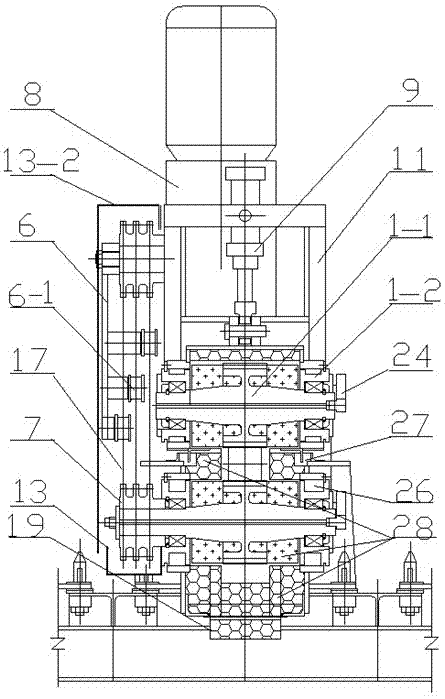

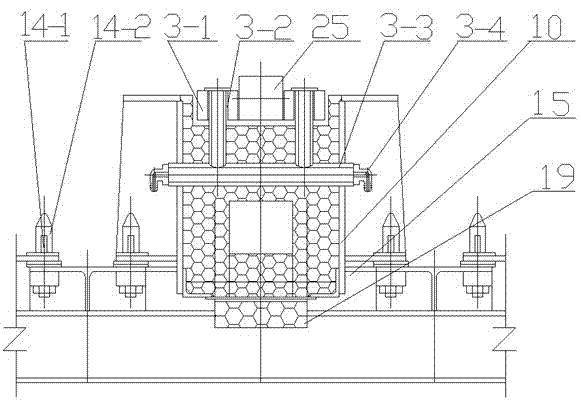

[0027] The invention provides a centralized lower transmission progressive tension leveling machine with a heat preservation device. There are three types of drive for this machine. The first type is a driving device with a frequency conversion motor speed regulation on the top of the transmission roller, through the sprocket chain system transmission. The second is through the cantilever open gear system on the transmission roller, through the coupling and the drive device with variable frequency motor speed regulation placed on both sides of the production line. The third is to connect the three transmission rollers with the distribution gearbox through universal joint shafts, and then connect with the driving device with variable frequency motor speed regulation.

[0028] Such as figure 1 and figure 2As shown, it is a centralized lower-drive progressive tension leveling machine with heat preservation device of the first structure, including a speed reducer 8 with frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com