Underdriving progressive withdrawal and straightening machine with heat insulation device

The technology of a heat preservation device and a tension leveling machine is applied in the field of progressive tension leveling machines with lower transmission, which can solve the problems of consuming large cooling water billet temperature, affecting the life of electromechanical equipment, and increasing metal oxidation losses, achieving easy descaling and simple and convenient adjustment. , the effect of less oxidation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

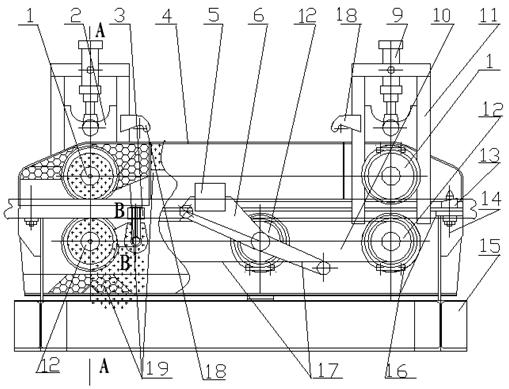

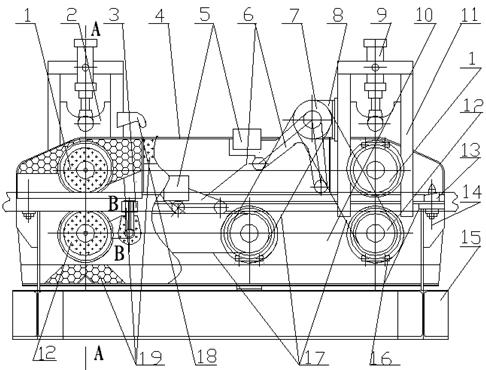

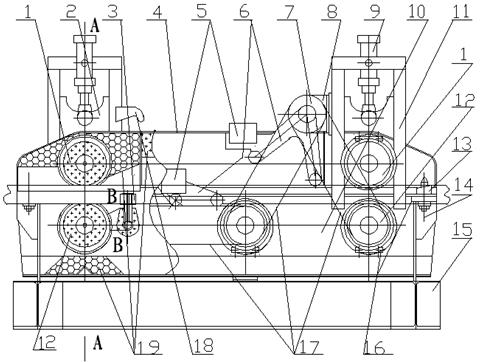

[0024] Such as figure 1 and image 3 As shown, the present invention provides a lower-drive progressive tension leveler with a thermal insulation device, including a drive roller 12 fixed on a tension leveler base 10 lined with refractory castables. The drive roller 12 located in the middle is connected with the speed reducer 20 with variable frequency motor speed regulation through a shaft coupling 23, and the speed reducer 20 with frequency conversion motor speed regulation is installed on the electromechanical support 21. The sprocket wheel on the driving roller 12 in the middle drives each driving roller 12 before and after it by a chain 17 . Above respectively a driving roller 12 before and after being positioned at middle driving roller 12, also respectively have a driven roller 1 that is contained on the lifting guide cover device 2. The driven roller 1 moves up and down on the hydraulic cylinder support 11 to press the steel billet 25 by the hydraulic cylinder 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com