Closed in-column concrete pouring method

A concrete and closed technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, sampling devices, and preparation of test samples. It can solve problems such as storage, concrete voids, and difficult control of concrete density. Guarantee the quality of perfusion and ensure the effect of compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

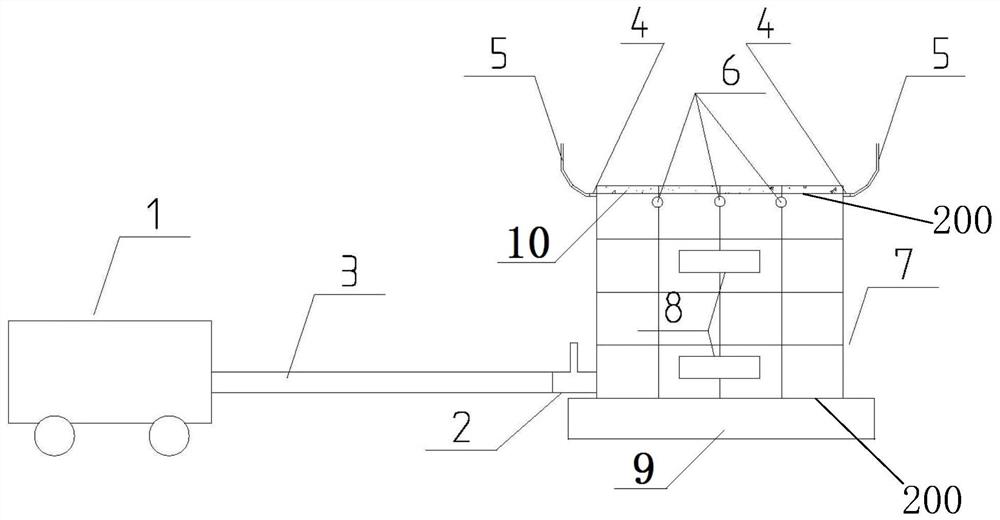

[0074] Such as figure 1 and figure 2 As shown, the method for pouring concrete in the closed column may further comprise the steps:

[0075] Step 1, construction preparation, cleaning up the sundries on the construction joint surface 200;

[0076] Step 2, building pile formwork 7;

[0077] Step 3, connect the pipeline;

[0078] Step 4, pouring concrete:

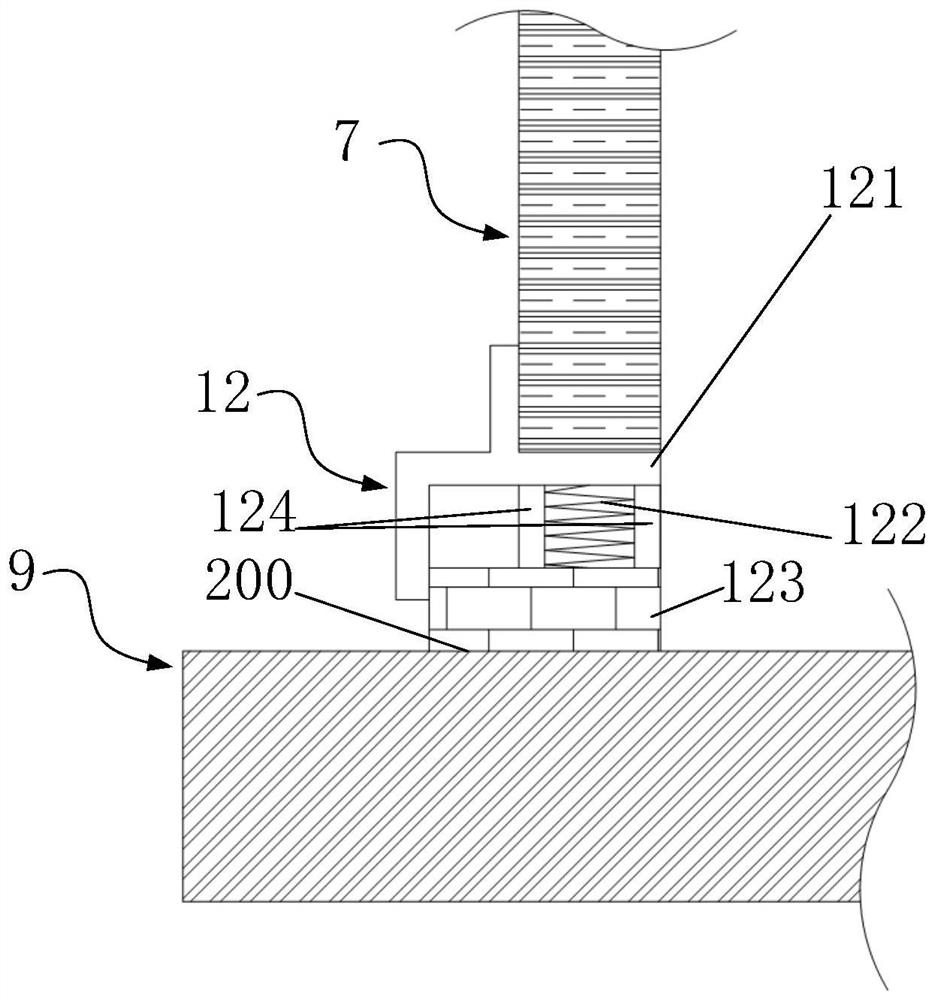

[0079] Step 4.1, laying a concrete base on the construction joint surface 200 of the permanent underpinning beam 9, the upper end of the concrete base is lower than the height of the stop valve 2, and the thickness of the concrete base is 15mm;

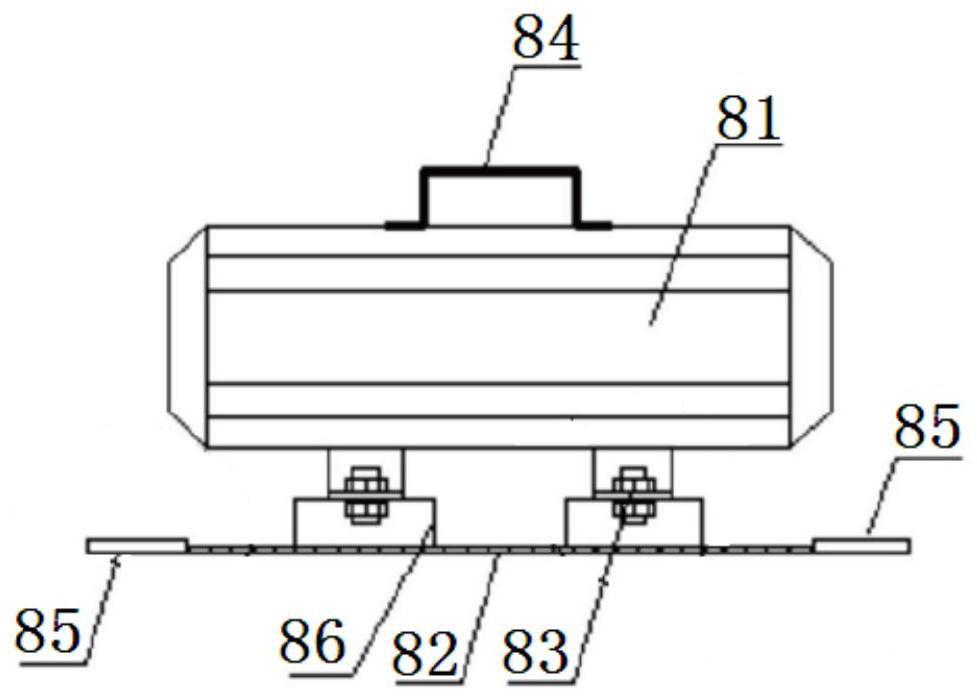

[0080] Step 4.2, pouring the concrete solid layer on the concrete base, the concrete solid layer pouring is carried out in layers, and the pouring thickness is not greater than 1.25 times the length of the action part of the attached v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com