Online testing system of polymer cushion stress loading and testing method

A stress loading and online testing technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem of low accuracy and reliability of test data, difficult synchronization and coordination of compression nuts, and inability to achieve stress autonomous loading. and other problems, to achieve the effect of improving the level of automation technology, improving reliability and data security, and detecting accurate and reliable data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

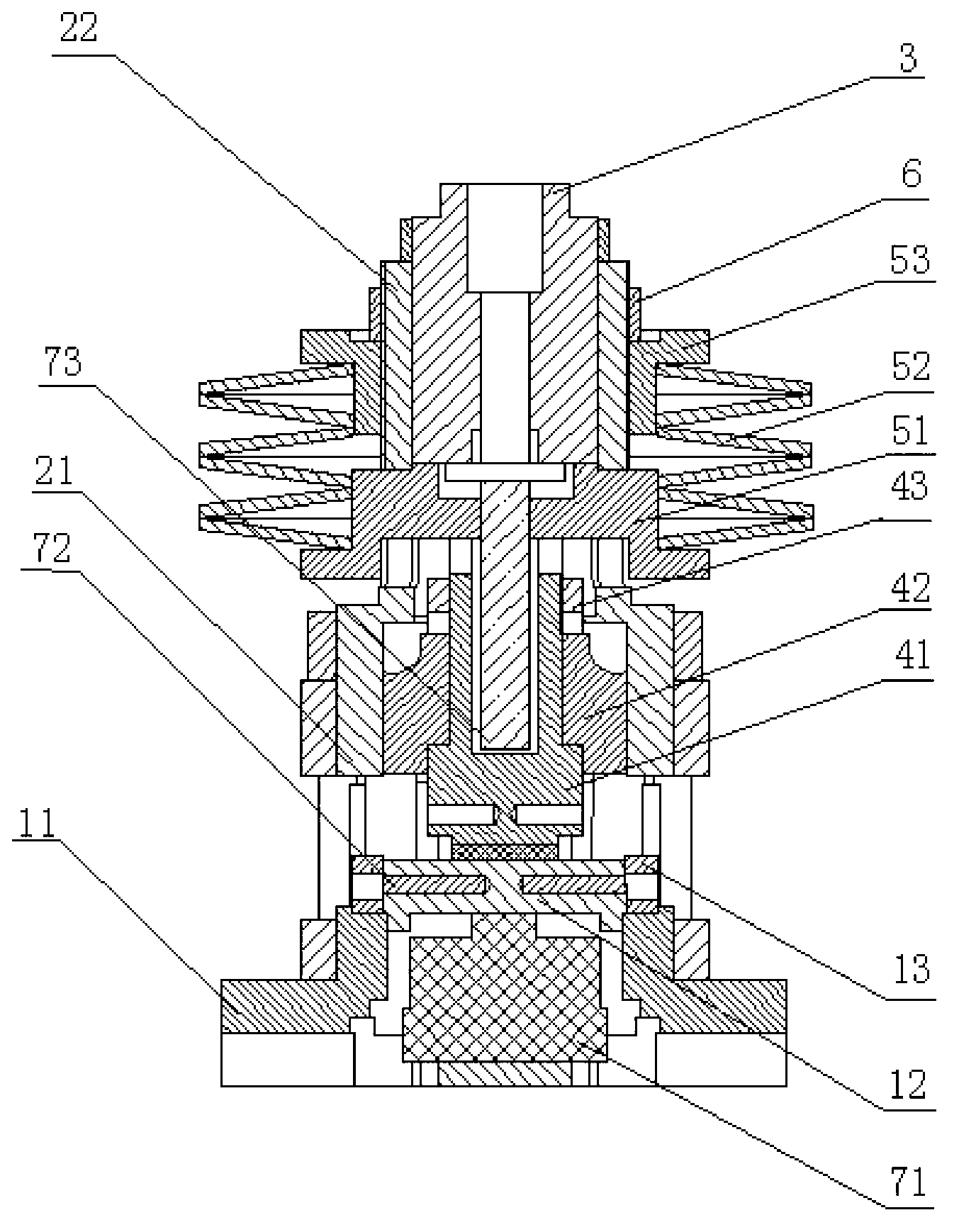

[0043] An on-line testing system for stress loading of polymer cushions is composed of a stress loading device and an online detection system; the stress loading device is composed of a base assembly, a sample sleeve, a pressure column assembly, a force application assembly and a limit rod from bottom to top; The base assembly is composed of a base 11, a sample backing plate 12 and a limit backing plate 13 located in the middle of the upper end surface of the base 11, the cushion layer sample is located on the sample backing plate 12, and a temperature sensor plug is left on the side of the sample backing plate 12. hole; the sample casing is composed of a lower hole tube 21 and an upper hole tube 22, the lower hole tube 21 is installed with a pressure column assembly, the upper hole tube 22 is equipped with a force application component outside, and a limit rod 3 is installed inside, and the limit rod 3 is mainly It is used for the installation and positioning of the displaceme...

Embodiment 2

[0058] An on-line testing system for stress loading of polymer cushions is composed of a stress loading device and an online detection system; the stress loading device is composed of a base assembly, a sample sleeve, a pressure column assembly, a force application assembly and a limit rod from bottom to top; The base assembly is composed of a base 11, a sample backing plate 12 and a limit backing plate 13 located in the middle of the upper end surface of the base 11, the cushion layer sample is located on the sample backing plate 12, and a temperature sensor plug is left on the side of the sample backing plate 12. hole; the sample casing is composed of a lower hole tube 21 and an upper hole tube 22, the lower hole tube 21 is installed with a pressure column assembly, the upper hole tube 22 is equipped with a force application component outside, and a positioning rod 3 is installed inside, and the limit rod 3 is mainly used For the installation and positioning of the displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com