Fabric creep and relaxation measurement method and device

A technology of testing device and testing method, which is applied in the direction of using stable tension/pressure to test the strength of materials, etc., can solve problems such as large creep and relaxation, undetermined performance indicators of embroidery base fabrics, and deformation of embroidery patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

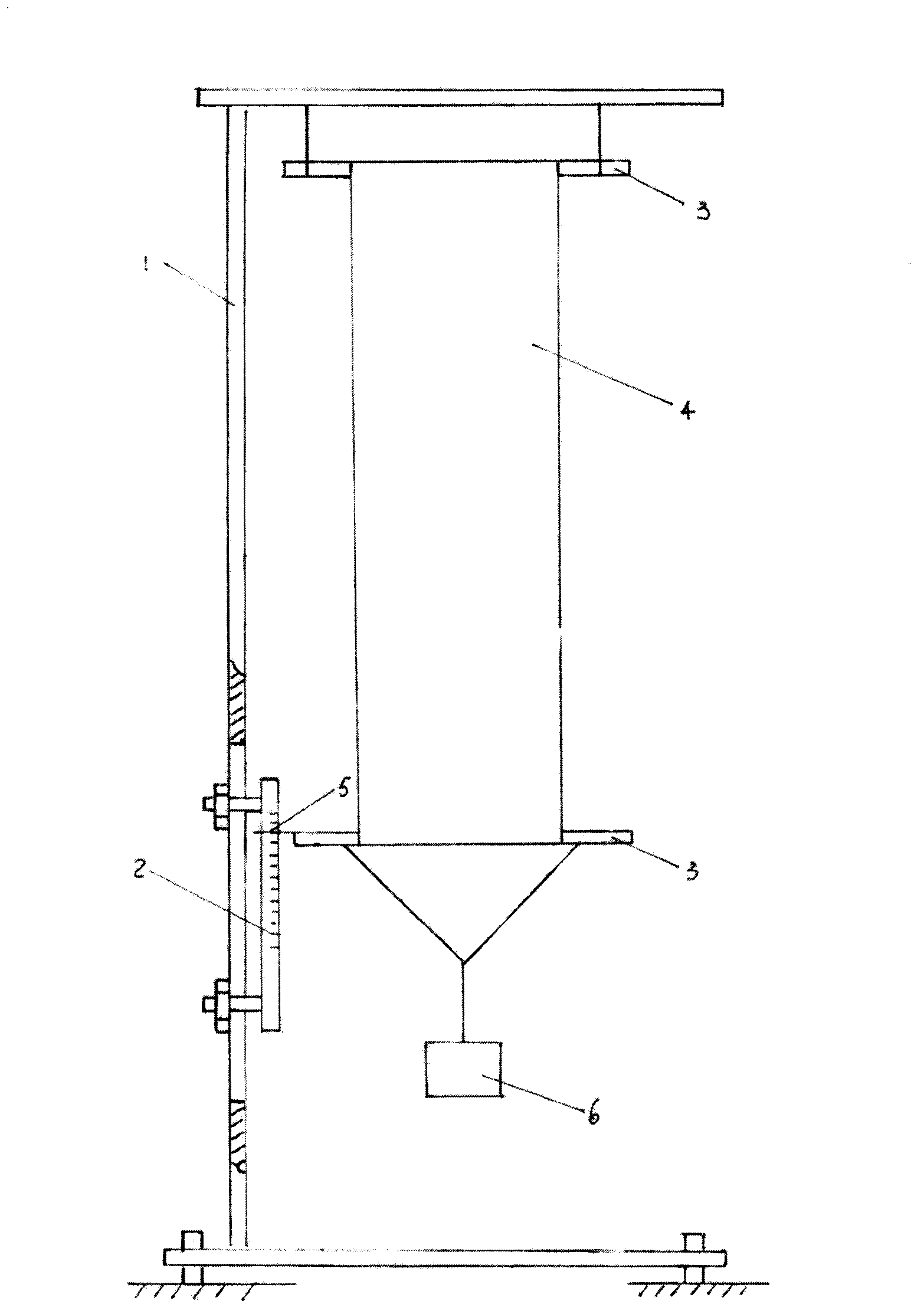

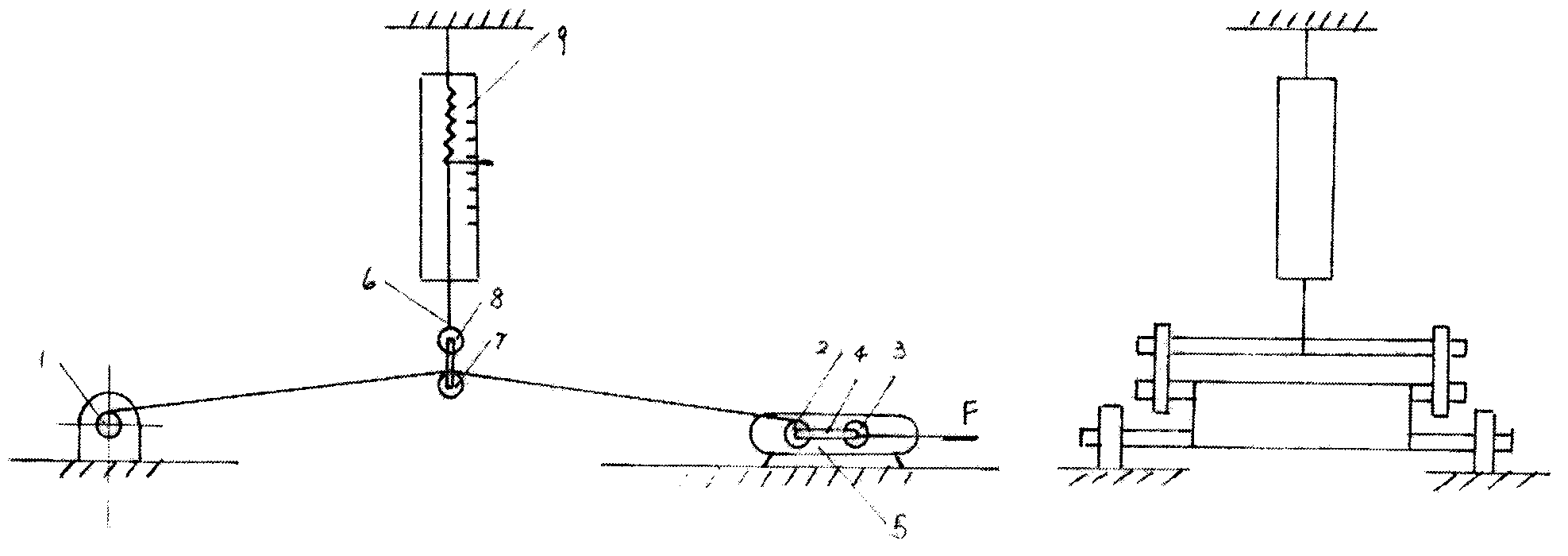

[0008] Example 1: Fabric relaxation measurement:

[0009] (1) Fabric type: crepe satin

[0010] Fabric size: 30cm×100cm

[0011] Fabric material: 100% mulberry silk

[0012] Fabric warp density: 129.3 threads / cm

[0013] Fabric weft density: 50 threads / cm

[0014] Fabric weight: 81 g / m²

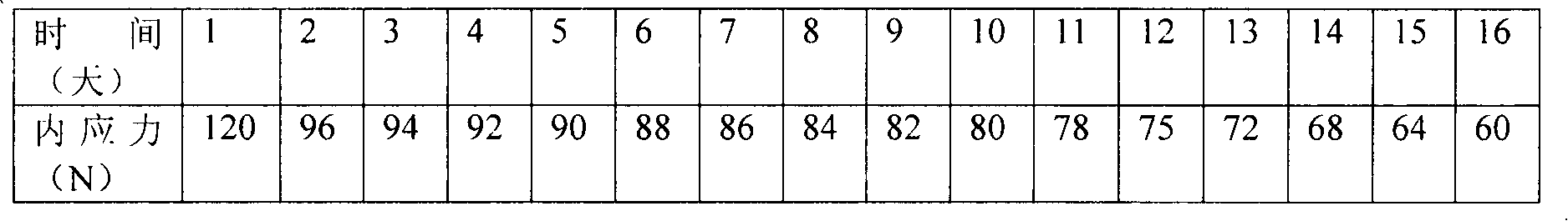

[0015] Measurement data:

[0016]

[0017] (2) Fabric type: Jiabao satin

[0018] Fabric size: 30cm×100cm

[0019] Fabric material: 100% mulberry silk

[0020] Fabric warp density: 104.3 threads / cm

[0021] Fabric weft density: 34 threads / cm

[0022] Fabric weight: 96 g / m²

[0023] Measurement data:

[0024]

Embodiment 2

[0025] Embodiment 2: fabric creep measurement:

[0026] (1) Fabric type: crepe satin

[0027] Fabric size: 30cm×100cm

[0028] Fabric material: 100% mulberry silk

[0029] Fabric warp density: 129.3 threads / cm

[0030] Fabric weft density: 50 threads / cm

[0031] Fabric weight: 81 g / m²

[0032] Fabric weight: 100N

[0033] Measurement data

[0034]

[0035] (2) Fabric type: Jiabao satin

[0036] Fabric size: 30cm×100cm

[0037] Raw material: 100% mulberry silk

[0038] Warp density: 104.3 roots / cm

[0039] Weft density: 34 threads / cm

[0040] Weight: 96 g / m²

[0041] Fabric weight: 100N

[0042] Measurement data:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com