Tensile stress relaxation testing device and method of rubber material

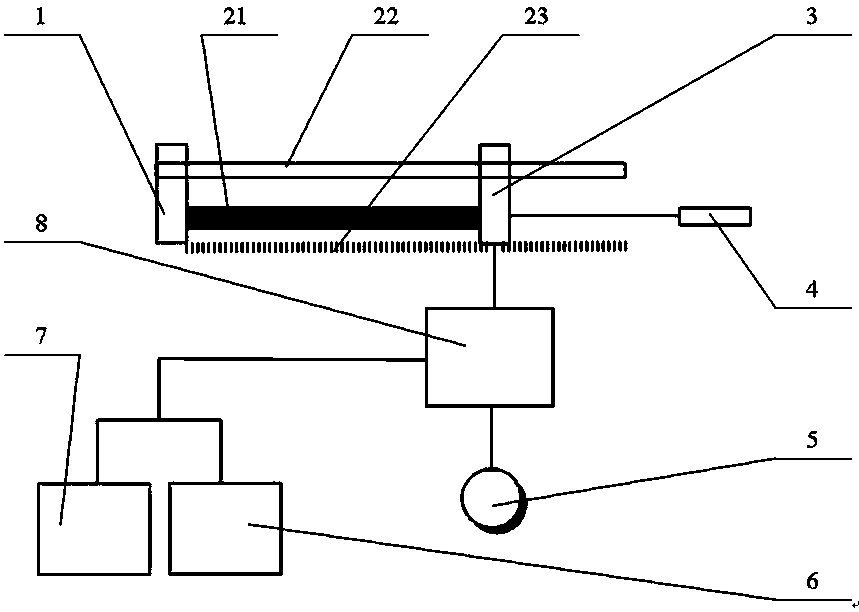

A technology of tensile stress and rubber materials, which is applied in the directions of measuring devices, analyzing materials, and using stable tension/pressure to test the strength of materials, etc., can solve the problems of long-term performance research of rubber materials, inability to obtain continuous online experimental data, Complicated device structure and other issues, to achieve the effect of easy actual operation, quick and effective judgment, and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

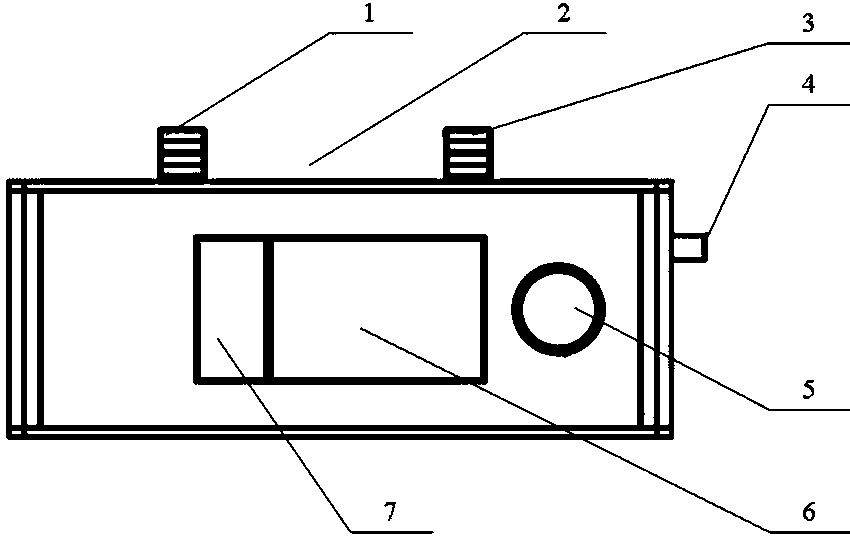

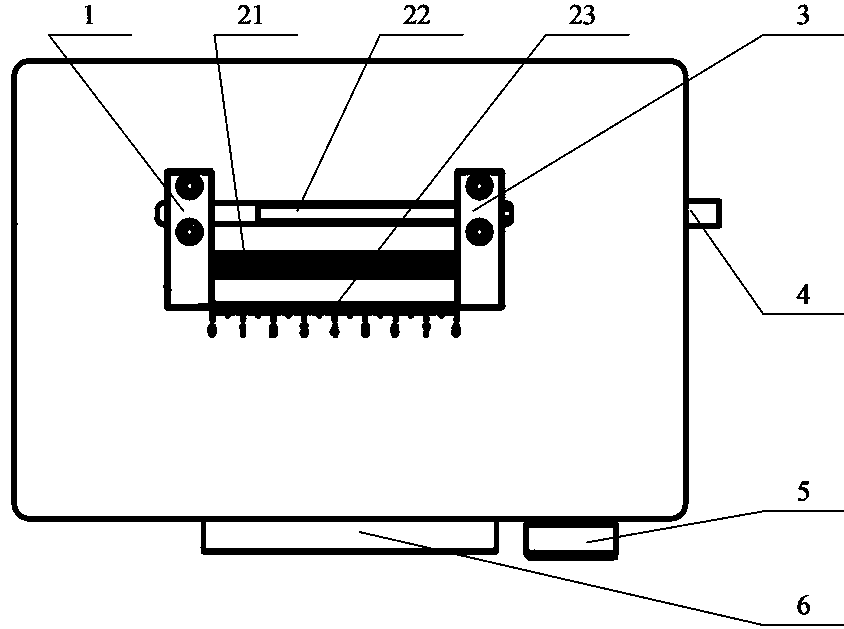

[0037] Clamp one end of the sample 21 of the cut dumbbell shape or rectangular bar on the fixed end 1 of the sample fixture, and clamp the other end on the moving end 3 of the sample fixture, and fix the sample 21; turn on the power switch 5, and set the initial tensile stress Return Fa to zero; rotate the jig movement adjustment knob 4, so that the moving end 3 of the sample jig moves to the right along the slide rail 22 until the sample 21 is naturally stretched, and the tensile stress data starts to be displayed on the data display screen 6 at this time; continue to rotate the jig Move the adjustment knob 4 until the sample 21 is stretched to the predetermined elongation, at this time, the tensile stress data displayed on the data display screen 6 is recorded as F; after 30 minutes, the corresponding tensile stress value is recorded as F0, and F0 is the sample 21 Initial tensile stress at a predetermined elongation; continue to maintain the position of the moving end 3 of th...

Embodiment 2

[0039] Clamp one end of the cut dumbbell-shaped or rectangular sample 21 on the fixed end 1 of the sample fixture, and clamp the other end on the moving end 3 of the sample fixture, and fix the sample 21; turn on the power switch 5, and record the initial tensile stress Fa; Rotate the jig movement adjustment knob 4 to make the sample jig moving end 3 move to the right along the slide rail 22 until the sample 21 is stretched naturally, at this time the tensile stress data is displayed on the data display screen 6; continue to rotate the jig movement adjustment Knob 4, until the sample 21 is stretched to the predetermined elongation, at this time, the tensile stress data displayed on the data display screen 6 is recorded as F; after 30 minutes, the corresponding tensile stress value is recorded as F0, and F0 is the sample 21 at the predetermined Initial tensile stress under elongation; continue to maintain the position of the moving end 3 of the sample fixture, and record the tim...

Embodiment 3

[0041] Clamp one end of a certain rubber material sample 21 of a dumbbell shape that has been cut into the fixed end 1 of the sample fixture, and clamp the other end in the moving end 3 of the sample fixture, and fix the sample 21; turn on the power switch 5, and set the initial tensile stress Return Fa to zero; rotate the jig movement adjustment knob 4, so that the moving end 3 of the sample jig moves to the right along the slide rail 22 until the sample 21 is naturally stretched, and the tensile stress data starts to be displayed on the data display screen 6 at this time; continue to rotate the jig Move the adjustment knob 4 until the sample 21 is stretched to 200% elongation (that is, the sample is stretched to twice the original gauge length), and the tensile stress data displayed on the data display screen 6 is recorded as F; 30min Finally, the corresponding tensile stress value is recorded as F0, and F0 is the initial tensile stress of the sample 21 at a predetermined elo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com