Pseudo-triaxial test device based on dynamic fatigue testing machine

A dynamic fatigue and testing device technology, applied in measuring devices, using stable tension/pressure to test material strength, instruments, etc., to achieve the effects of high control accuracy, complete protection functions, and strong anti-pollution capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

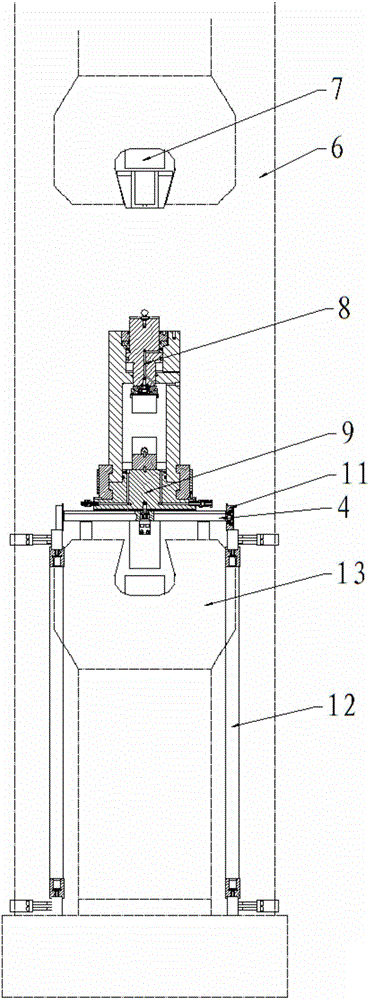

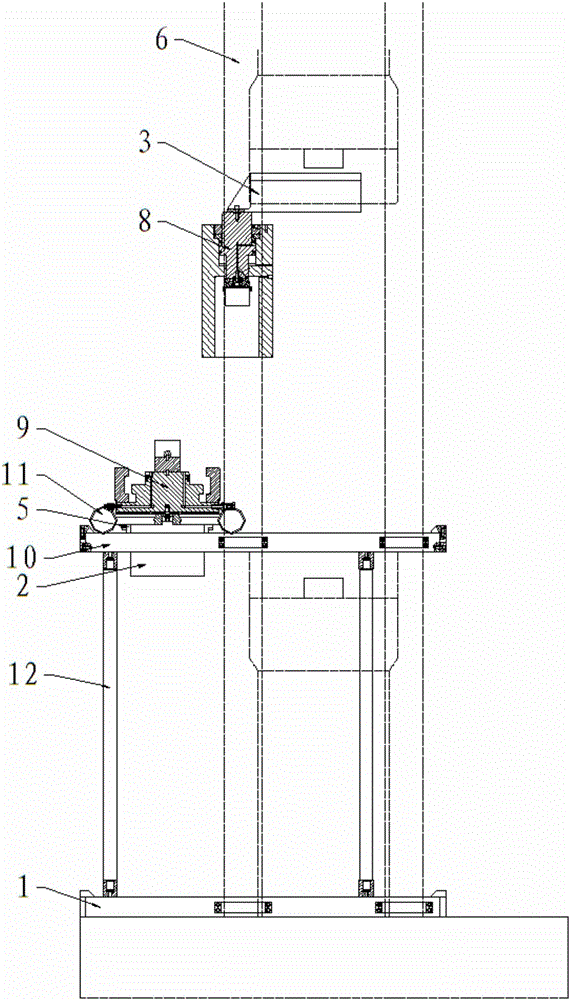

[0028] This embodiment provides a pseudo-triaxial testing device based on a dynamic fatigue testing machine, the structure of which is as follows: figure 1 , figure 2 As shown, including the column 6, the upper and lower ends of the column 6 are respectively provided with an upper hydraulic chuck and a lower hydraulic chuck 13, the upper hydraulic chuck is connected to the upper end of the upper pressure column 7, and the lower end of the upper pressure column 7 is connected to the upper connection block 3, The lower end of the upper connection block 3 is fixedly equipped with a pressure chamber main body 8, and the pressure chamber base 9 is correspondingly provided below the pressure chamber main body 8, and the pressure chamber base 9 is fixedly installed on the trolley, and at least two square axles 4 and square axle 4 Wheels 11 are respectively installed at both ends, and the wheels 11 are arranged on the guide rail 10, and the guide rail 10 is horizontally installed in ...

Embodiment 2

[0032] The present embodiment provides a pseudo-triaxial test method based on a dynamic fatigue testing machine, comprising the following specific steps:

[0033] Step (1), assemble the sample into a sample assembly as required;

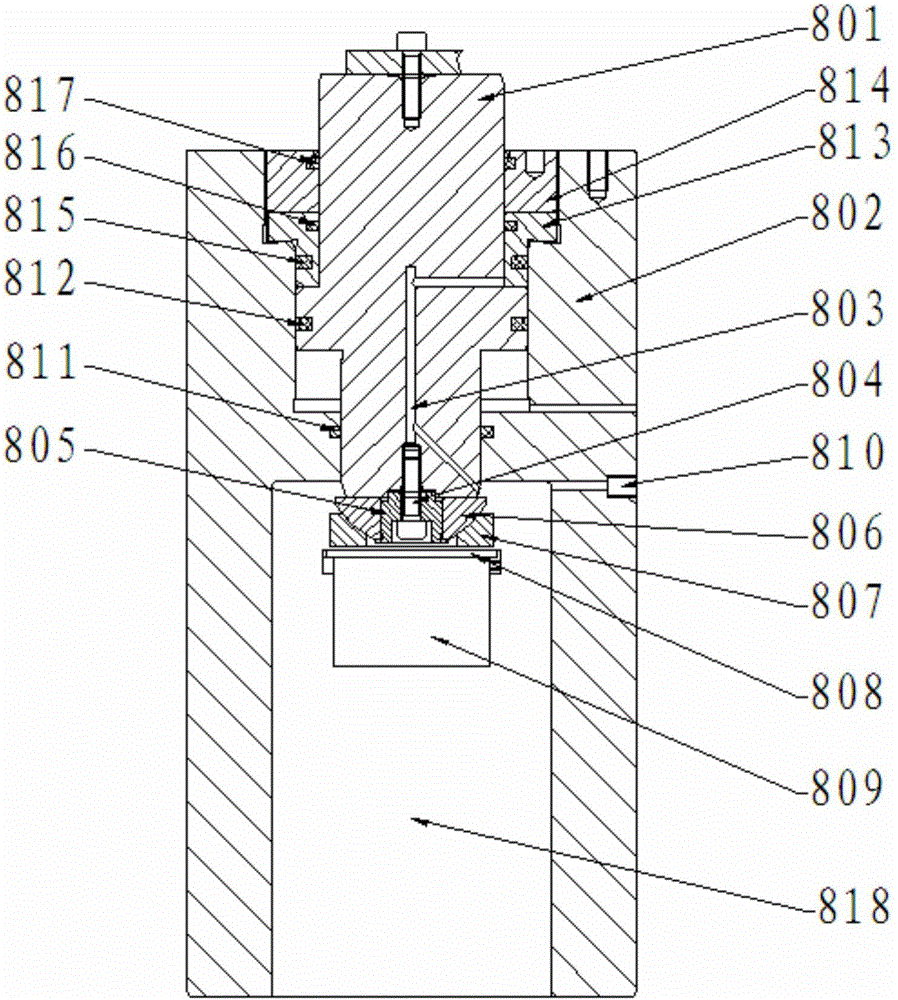

[0034] Step (2), install the cushion block on the pressure chamber base 9, and then place the sample assembly on the cushion block, the cushion block includes the first cushion block 901 and the second cushion block 902, and the pressure chamber base 9, the first cushion block The column pin 903 is used for connection and positioning between the block 901 and the second pad 902, and the total height of the "pad + sample assembly + upper pad 809 + joint bearing seat" is not 290 ± 20mm, and the joint bearing seat includes The cushion cover 805, the outer spherical body 806 and the inner spherical body 807 are installed sequentially from the inside to the outside;

[0035] Step (3), hoist the main body 8 of the pressure chamber on the base 9 of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com