Test method for researching transformation mechanism of martensite in austenitic stainless steel

A technology of austenitic stainless steel and martensitic transformation, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of scrapping pressure vessels, user safety risks, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1304

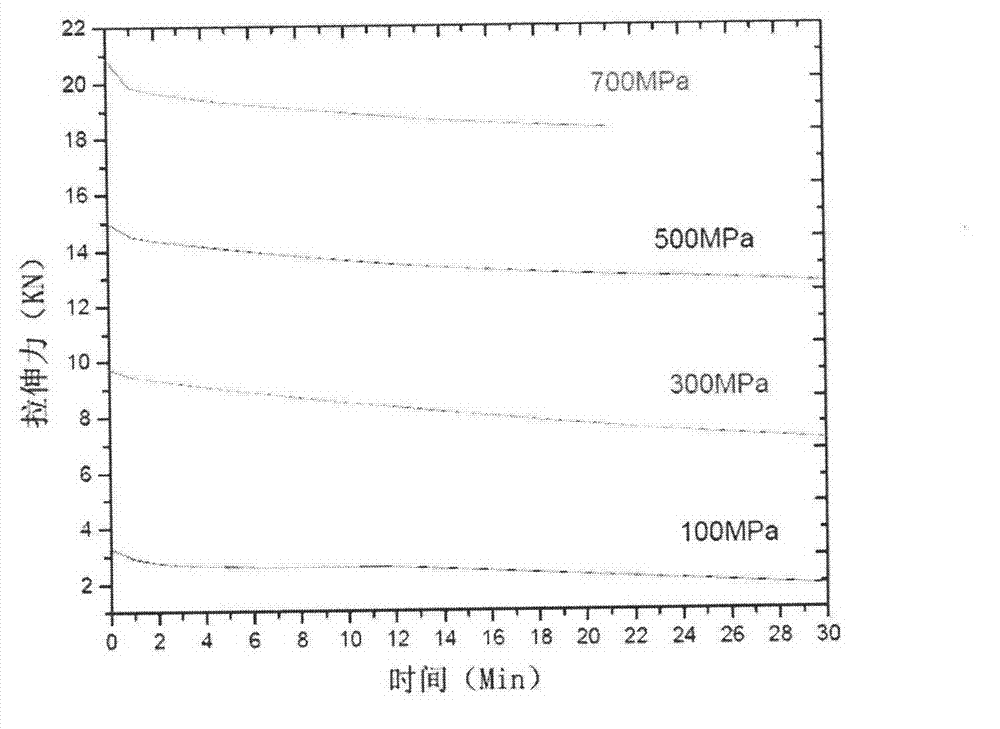

[0026] Stress relaxation test under embodiment 1304 stainless steel liquid nitrogen temperature

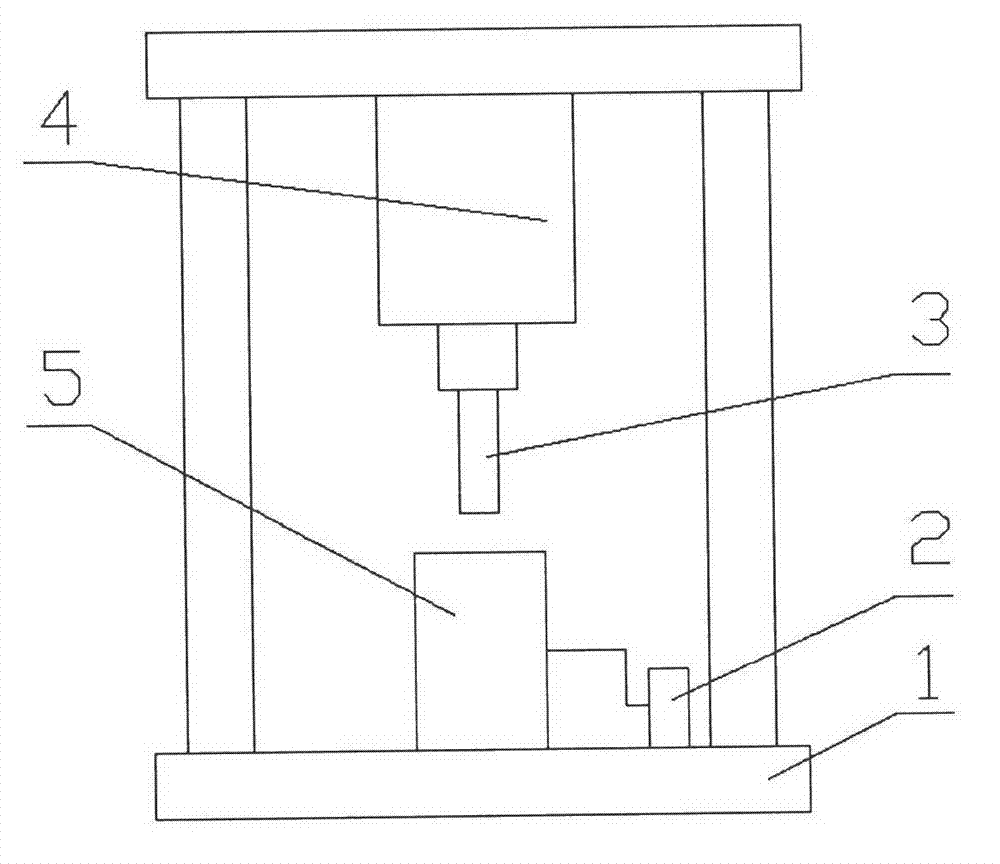

[0027] Such as figure 1 As shown, the low temperature stress relaxation test method of the present invention is carried out on the electro-hydraulic servo universal testing machine 1, and the sample 3 is 304 stainless steel, and the specific test steps are as follows:

[0028] I. sample 3 is contained in the cryogenic tank 5, pours liquid nitrogen, thermocouple 2 measures the temperature of the liquid nitrogen in the cryogenic tank 5, and the liquid nitrogen temperature is controlled at -196 ℃;

[0029] II. According to the cross-sectional size of sample 3 (a round bar sample with a diameter of Φ6mm), according to the formula "load = stress × cross-sectional area of the sample", calculate the test stress required for 100MPa, 300MPa, 500MPa, and 700MPa respectively. Load, through the automatic control program of the testing machine 1, load the sample 3 to the required load withi...

Embodiment 2

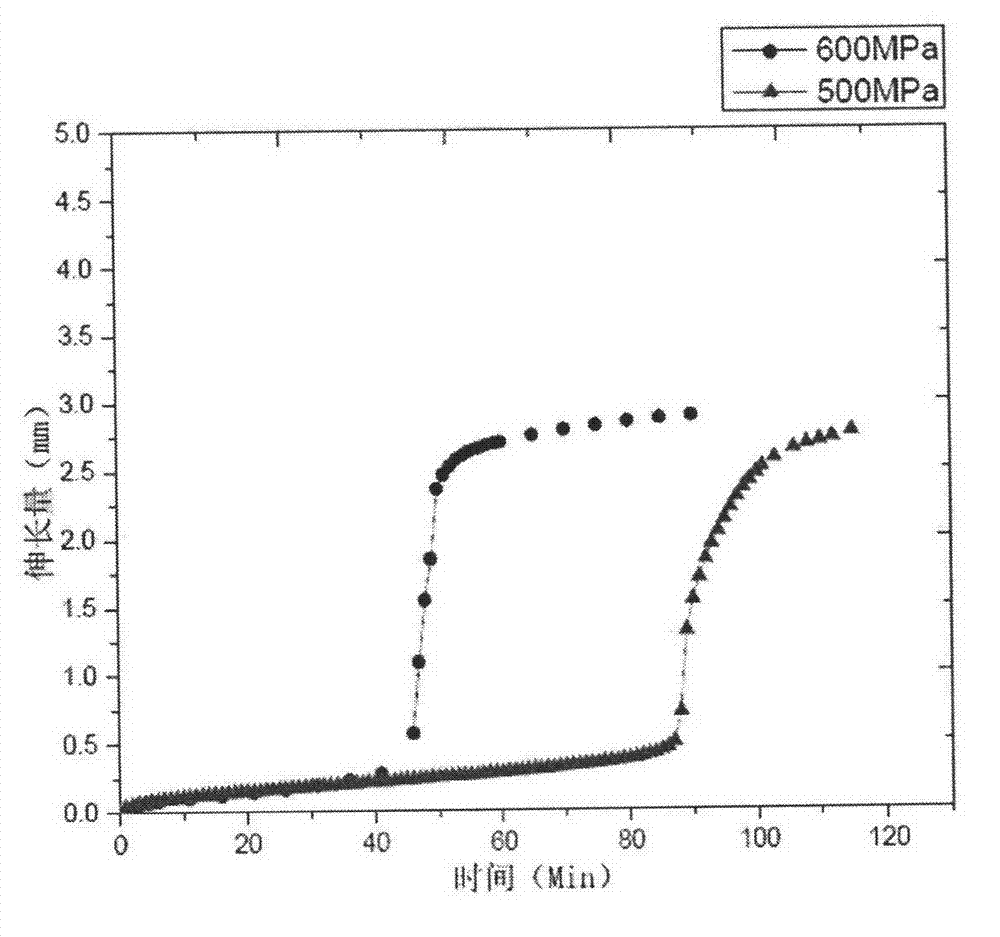

[0032] Example 2 Creep deformation test of 304 stainless steel at liquid nitrogen temperature

[0033] The test device used in this example, the sample type are identical with embodiment 1, and difference is that test load remains constant in this method, concrete steps are as follows:

[0034] I. sample 3 is contained in the cryogenic tank 5, pours liquid nitrogen, thermocouple 2 measures the temperature of the liquid nitrogen in the cryogenic tank 5, and the liquid nitrogen temperature is controlled at -196 ℃;

[0035] II. According to the cross-sectional size of sample 3 (a round bar sample with a diameter of Φ6mm), according to the formula "load = stress × cross-sectional area of the sample", calculate the load required for the test stress to be 500MPa and 600MPa respectively, and pass the test The automatic control program of machine 1 loads the sample 3 to the required load within 30 seconds and keeps the load constant;

[0036] III. Observe the change of sample defor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com