Multifunctional true triaxial flow solid coupling test system

A technology of fluid-solid coupling and test system, which is applied to the test system of seepage mechanics and mine disaster science, to study the field of rock mechanics, and can solve the problems of not considering the stress environment, not forming parameter equations, and failing to meet the test requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

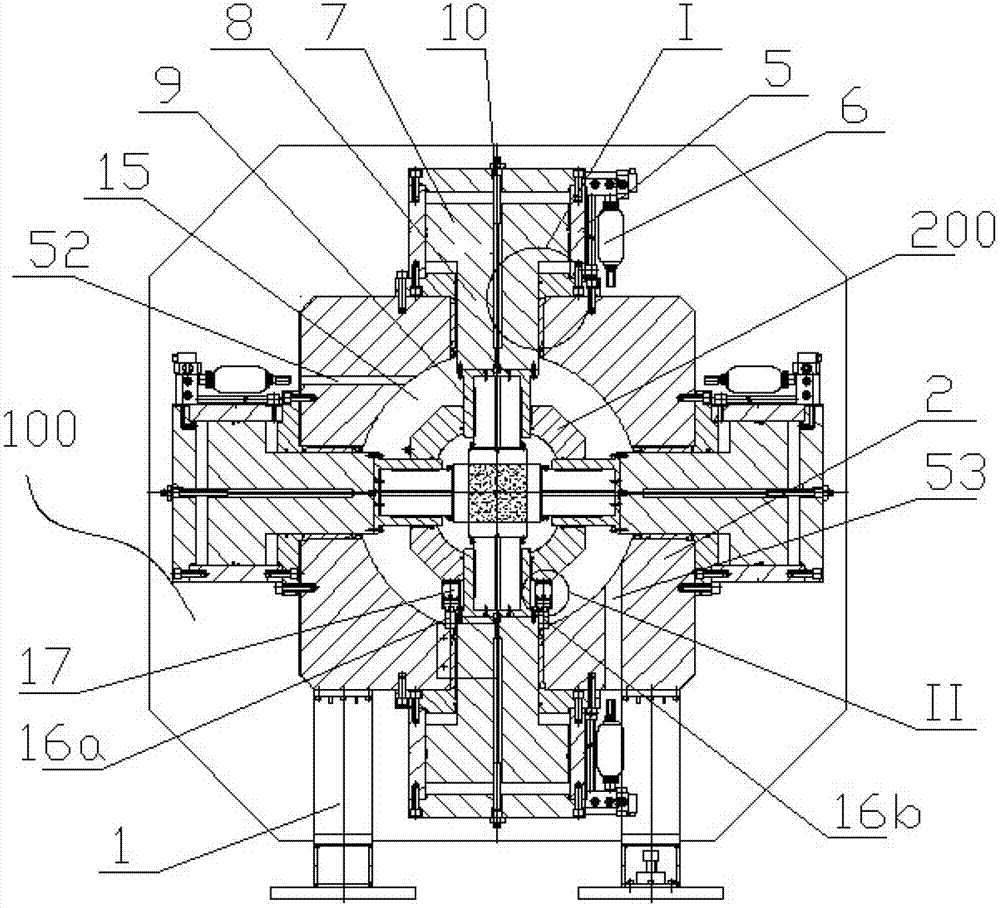

[0101] Such as Figure 1 to Figure 19 As shown, a multifunctional true triaxial fluid-solid coupling test system includes a frame 100 and a pressure chamber 200 in which coal and rock samples can be placed. The frame 100 includes a support 1 on which a frame 2 is fixedly connected.

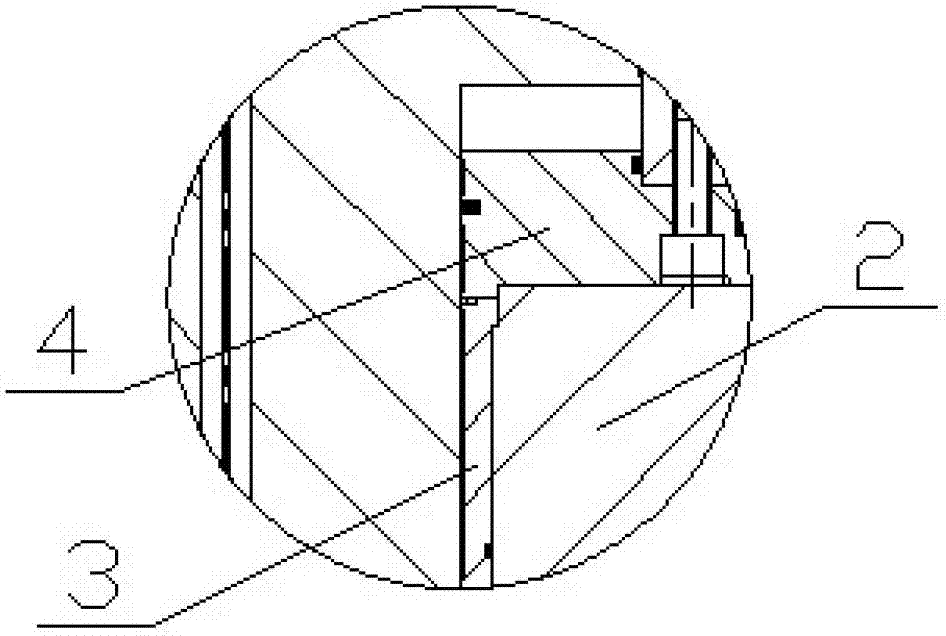

[0102] The upper part of the frame 2 is provided with the first bushing 3, the top of the frame 2 is fixedly connected with the first end cover 4, and the outer side of the first end cover 4 is fixed with the first oil cylinder 5, the first oil cylinder 5 and the first servo oil circuit 6 connections. A first oil cylinder piston 7 and a first oil cylinder piston rod 8 are integrally arranged in the first oil cylinder 5 , and a first oil cylinder displacement sensor 10 is arranged in the first oil cylinder piston 7 and the first oil cylinder piston rod 8 .

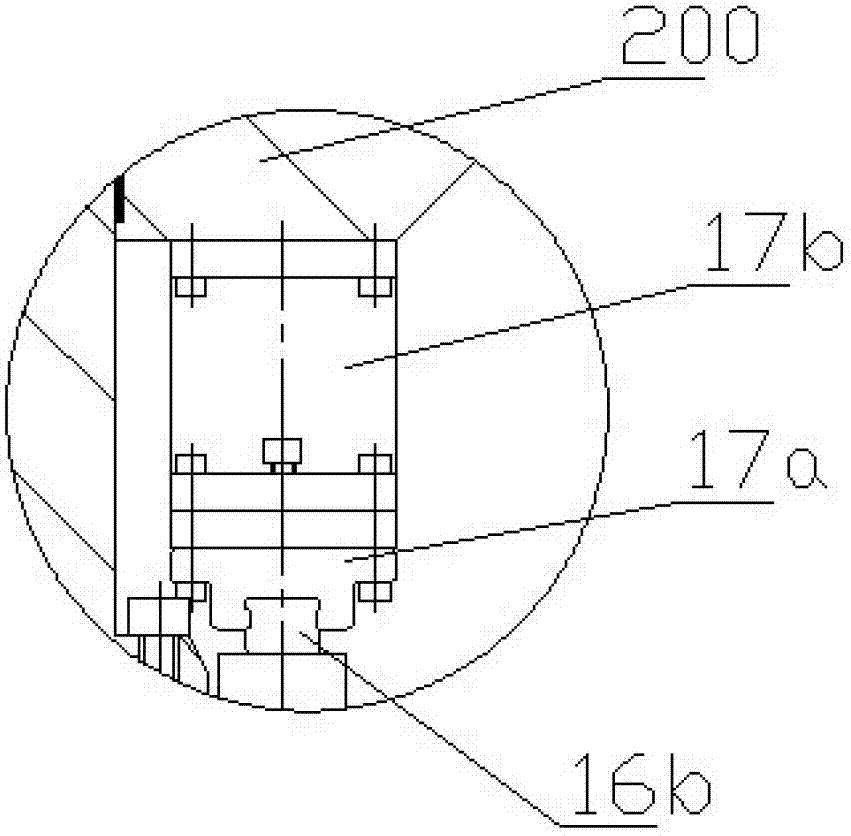

[0103] The lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com