Coal sample seepage test method under true triaxial state

A test method, true triaxial technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, permeability/surface area analysis, etc., can solve the lack of quantitative analysis, cannot meet the test requirements, and has no formation parameters Equation etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The present invention will be further described below in conjunction with the drawings and embodiments:

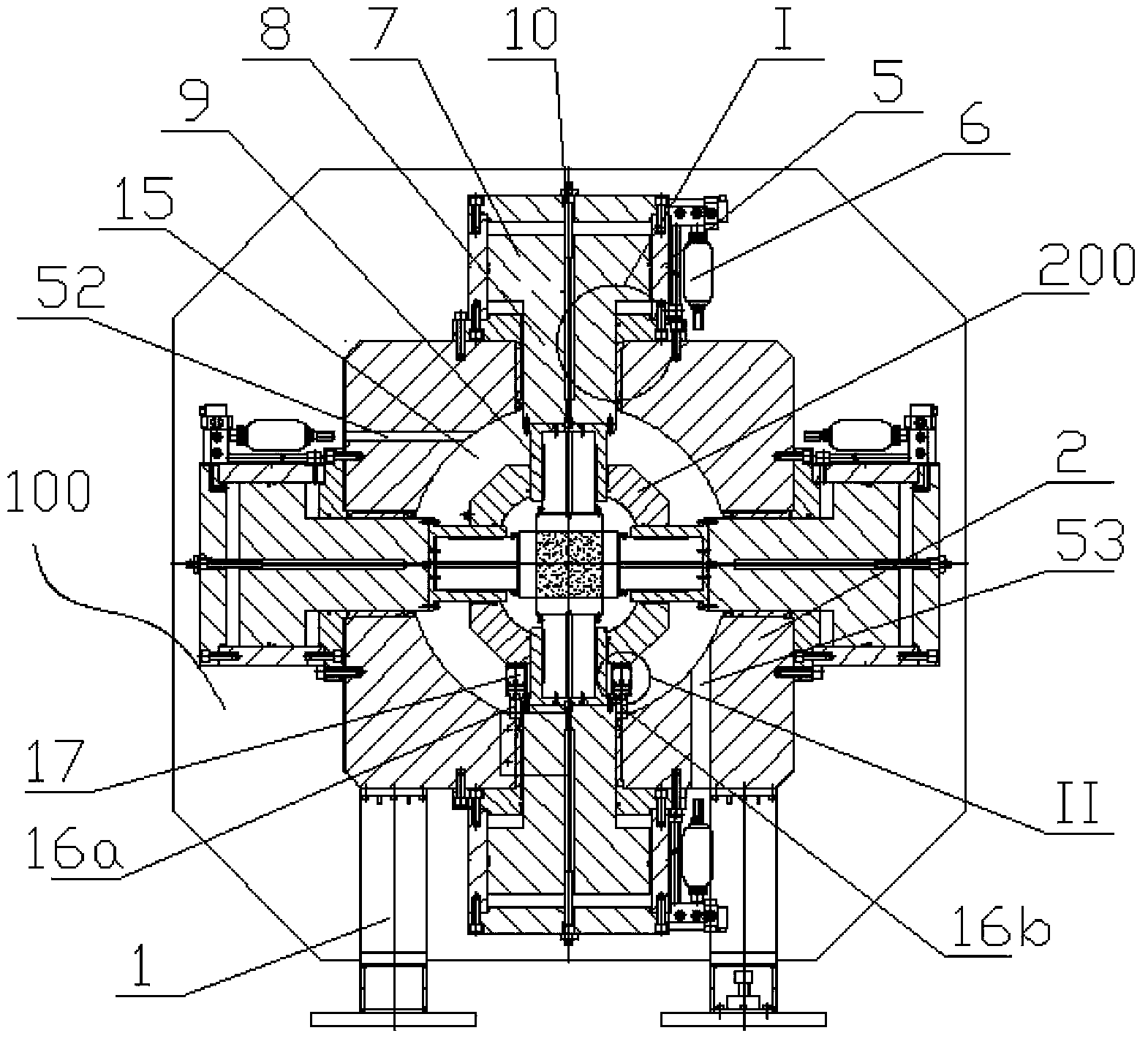

[0100] Such as Figure 1 to Figure 19 As shown, a multifunctional true triaxial fluid-solid coupling test system includes a frame 100 and a pressure chamber 200 in which coal and rock samples can be placed. The frame 100 includes a support 1 and a frame 2 is fixedly connected to the support 1.

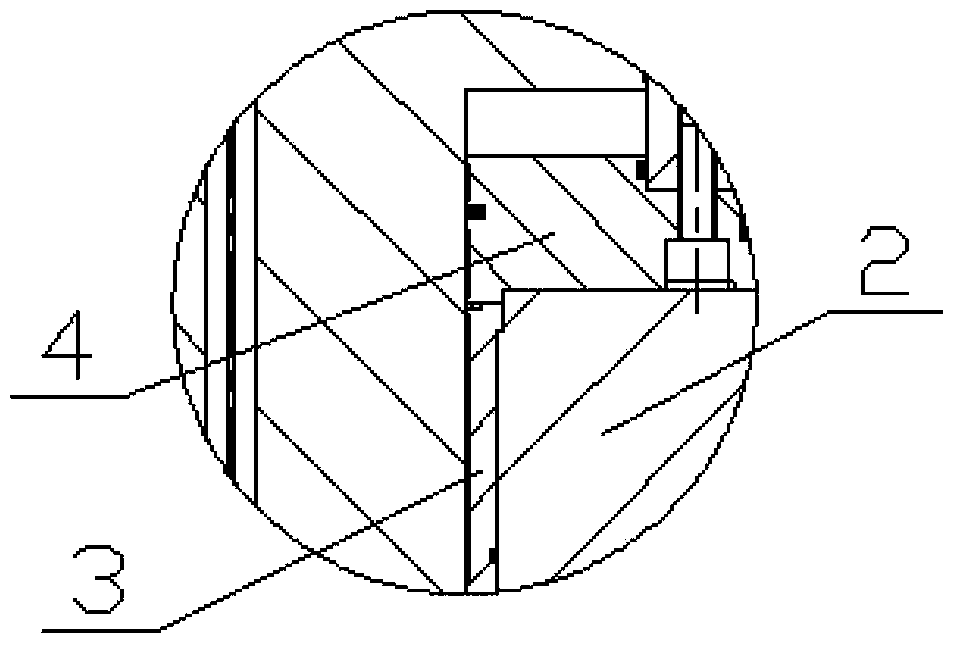

[0101] The upper part of the frame 2 is provided with a first bushing 3, the top of the frame 2 is fixedly connected with a first end cover 4, the outer side of the first end cover 4 is fixed with a first oil cylinder 5, the first oil cylinder 5 and the first servo oil circuit 6Connect. The first oil cylinder 5 is integrally provided with a first oil cylinder piston 7 and a first oil cylinder piston rod 8, and the first oil cylinder piston 7 and the first oil cylinder piston rod 8 are provided with a first oil cylinder displacement sensor 10.

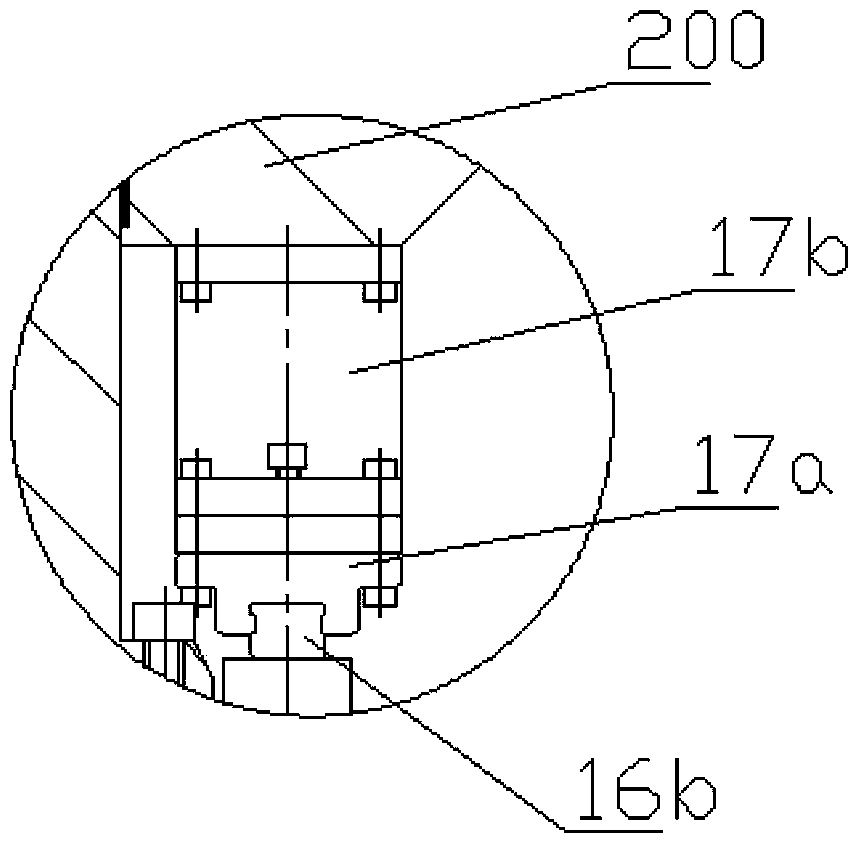

[0102] The lower part of the frame 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com