Tunnel construction simulation plane strain model test device

A model test, plane strain technology, applied in the direction of measuring device, using stable tension/pressure test material strength, machine/structural component testing, etc., can solve the problem of unsustainable load time, insufficient load stability, and inability to Reflect the actual situation of formation stress and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

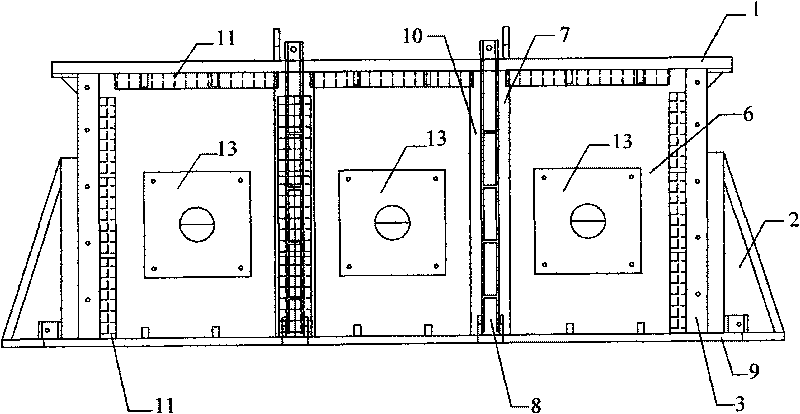

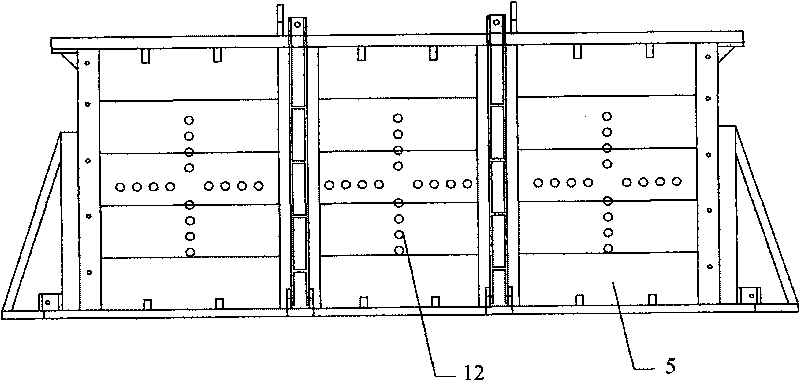

[0028] refer to figure 1 , figure 1 It is a simple structural block diagram of an embodiment of the tunnel construction simulation plane strain model test bench device of the present invention.

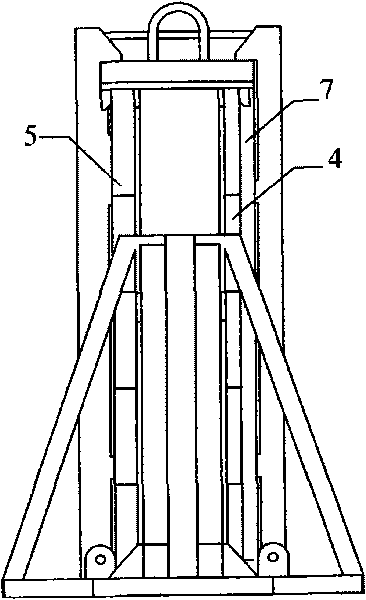

[0029] The test bench device includes a model bench, a loading system, and a data acquisition system; among them, the model bench is used to provide a space for holding the test model and to provide reaction force for the loading system; the loading system includes multiple loading bodies, which are used to simultaneously control different The loading body is used to carry out at least one set of loading body loading tests on the test model; the data acquisition system is used to detect the real-time displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com