True triaxial loading and unloading test device for large-size bedded pressure-bearing rock and testing method

A test device, loading and unloading technology, applied in the direction of measuring device, using stable tension/pressure to test material strength, suspension and porous material analysis, etc., can solve the problem of inability to simulate the three-dimensional stress state of pressure-bearing rock, and the inability to study Issues such as the influence law of intermediate principal stress and layered rock permeability characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The scheme of the present invention is described in further detail below in conjunction with the accompanying drawings and specific embodiments:

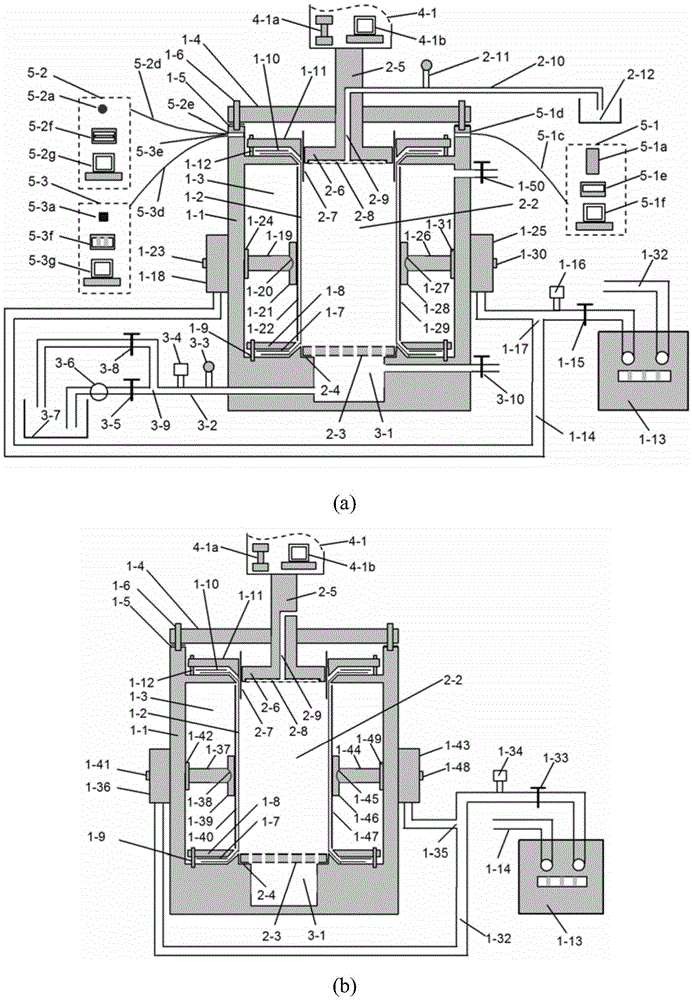

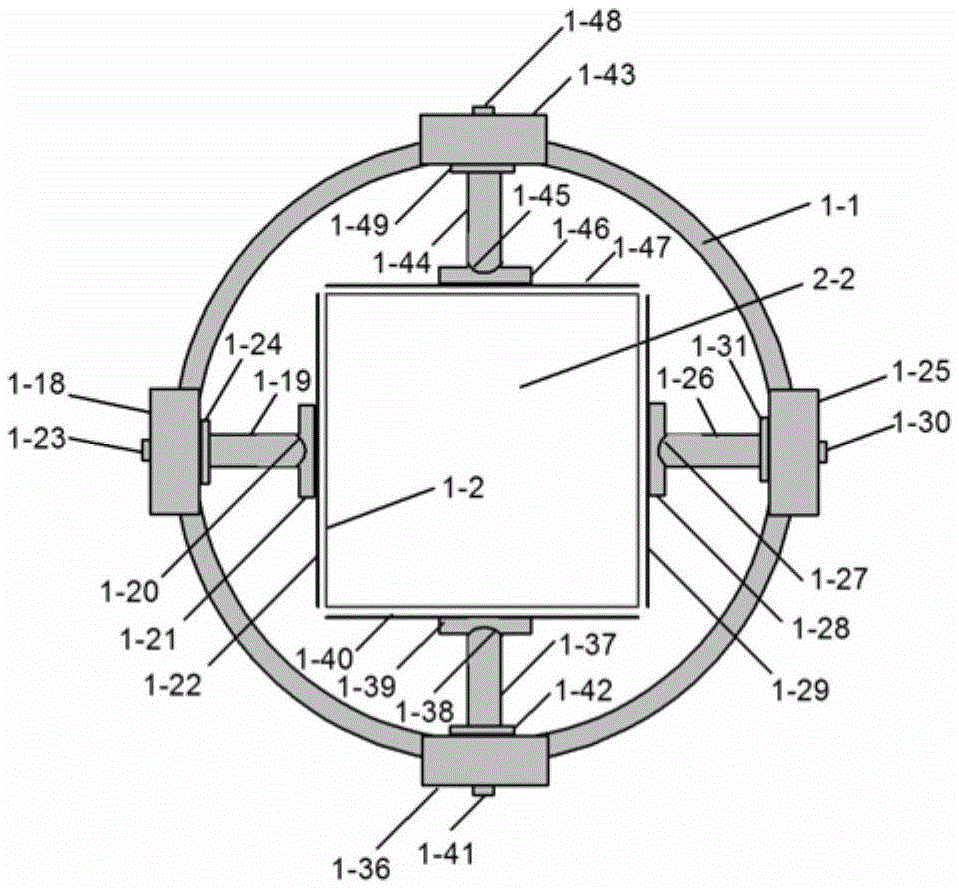

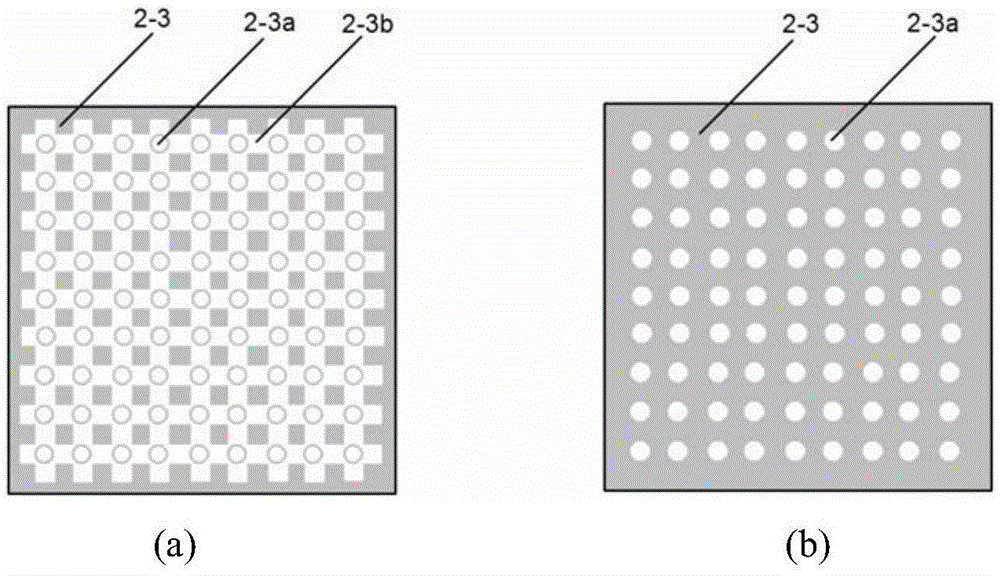

[0042] Such as figure 1 and figure 2 As shown, a true triaxial loading and unloading test device for large-scale layered confined rock is composed of a confining pressure loading module, a sample storage and water outlet module, a confined water loading module, a load loading module, and a signal acquisition and processing system. The confining pressure loading module is composed of two sets of mutually independent and perpendicular horizontal loading and unloading systems, which can load and unload the wrapped sample storage and water outlet modules in the horizontal direction in two mutually perpendicular directions. The pressurized water loading module is located at the bottom of the sample storage and water outlet module to load and unload the pressurized water at the bottom of the layered rock. The load loading module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com