On-line prediction method for high-temperature pipe damage and longevity

A prediction method and life-span technology, which can be used in the application of stable tension/pressure to test the strength of materials, special data processing applications, instruments, etc., which can solve the problems of difficulty in ensuring accuracy and inability to use online monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

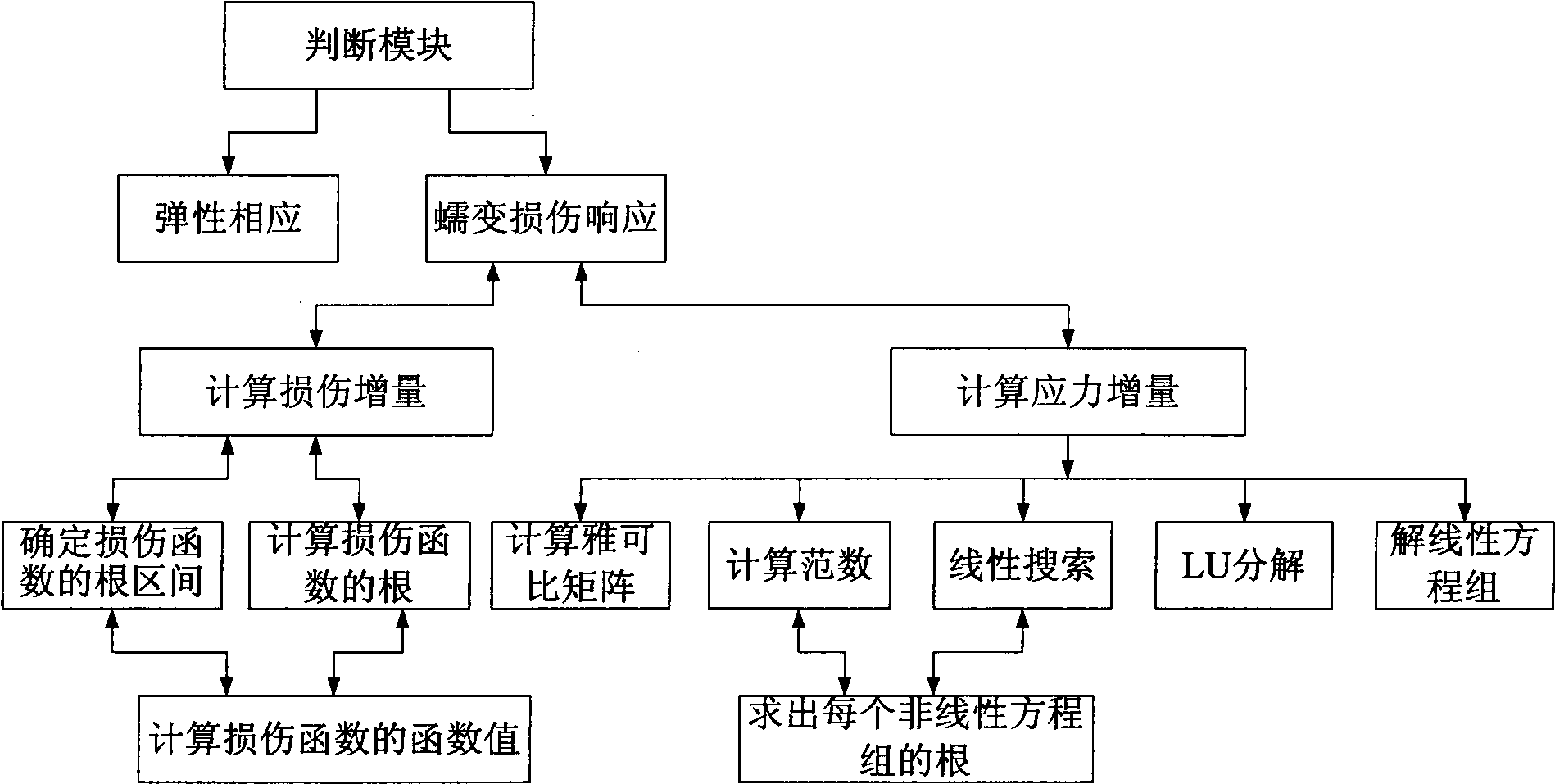

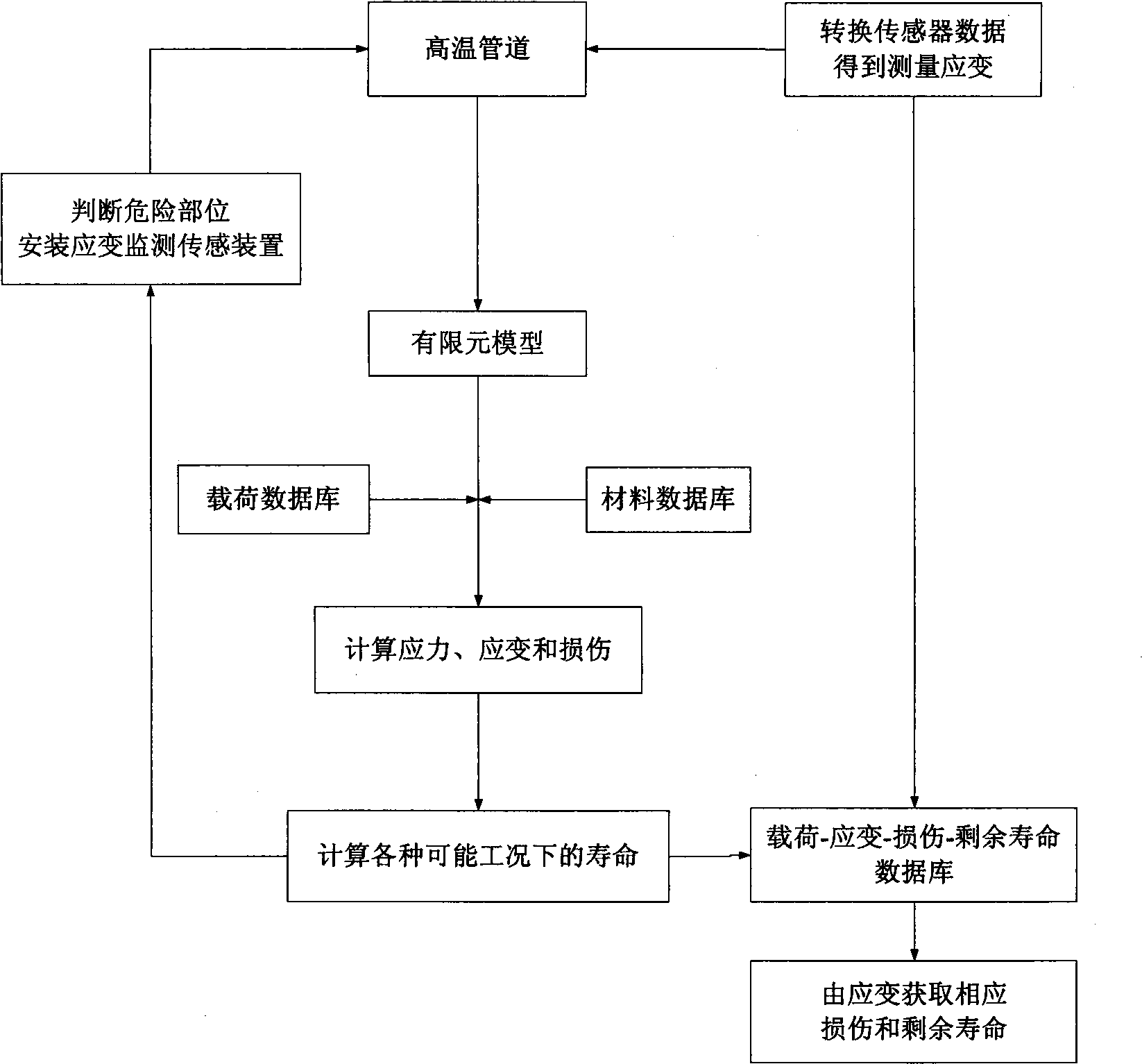

Method used

Image

Examples

Embodiment 1

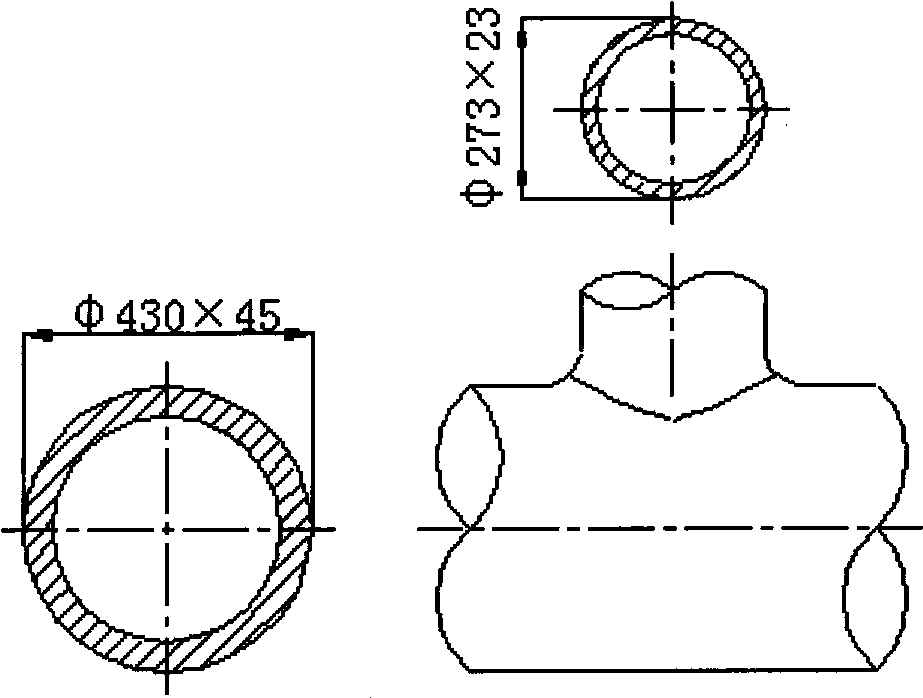

[0123] Example 1 On-line prediction of damage and service life of T-joints in pipeline systems

[0124] T-joint is a complex structure widely used in factories. Due to the structural discontinuity in the connecting part of the T-joint and the serious stress concentration near the connecting pipe, the T-joint area often fails first and Eventually lead to damage to the entire pipeline system. The creep damage development at the T-shaped joint is simulated by using the prediction method of the invention, and the corresponding strain-damage and strain-life databases are obtained through calculation.

[0125] Material properties

[0126] The material of the T-joint is 0.5Cr0.5Mo0.25V steel, and its creep parameters at 540°C are as follows:

[0127] Table 1 Material parameters of 0.5Cr0.5Mo0.25V steel at 540℃

[0128] E / MPa mu B n g φ A α v ρ 1.6×10 5 0.28 8.495×10 -37 14.45 0.725 1.472 7.963×10 -32 0.43 12.65 0.00534

[0129] Geomet...

Embodiment 2

[0133] Example 2 Prediction of damage and online life of pipe bends in piping systems

[0134] The elbow is the most common complex structure in the main steam pipeline, and it is a complex space surface component. Through the stress analysis of the main steam pipeline, it is found that the bent pipe is the most stressed part in the whole pipeline system. The prediction method of the invention is used to simulate the elbow position of the main steam pipeline of a certain power plant, and the corresponding strain-damage and strain-life databases are obtained through calculation.

[0135] Material properties

[0136] The material of the elbow is the same as in Example 1.

[0137] Geometry

[0138] The average radius of curvature R of the elbow m The pipe size is 1400mm, and the pipe size is 270×40mm. See the attached physical map and finite element grid Figure 9 And attached Figure 10 .

[0139] Using the prediction method of the present invention, the development o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com