Numerical simulation method for selective laser melting process

A technology of laser selective melting and numerical simulation, which is applied in the field of laser printing, can solve the problems of reducing the scrap rate and achieve the effect of preventing warping and optimizing printing parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] Adopt following technology in the numerical simulation method of a kind of laser selective melting process of the present invention:

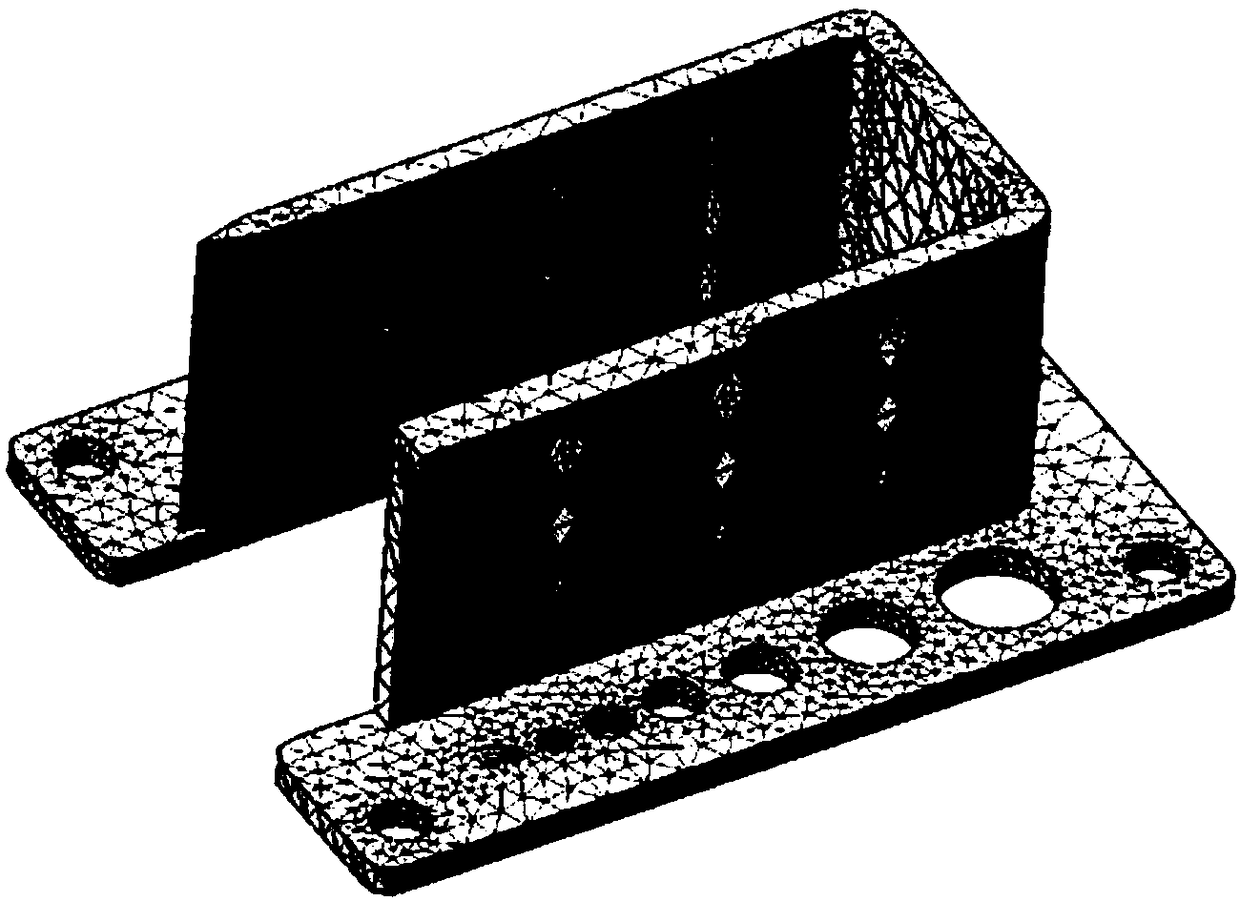

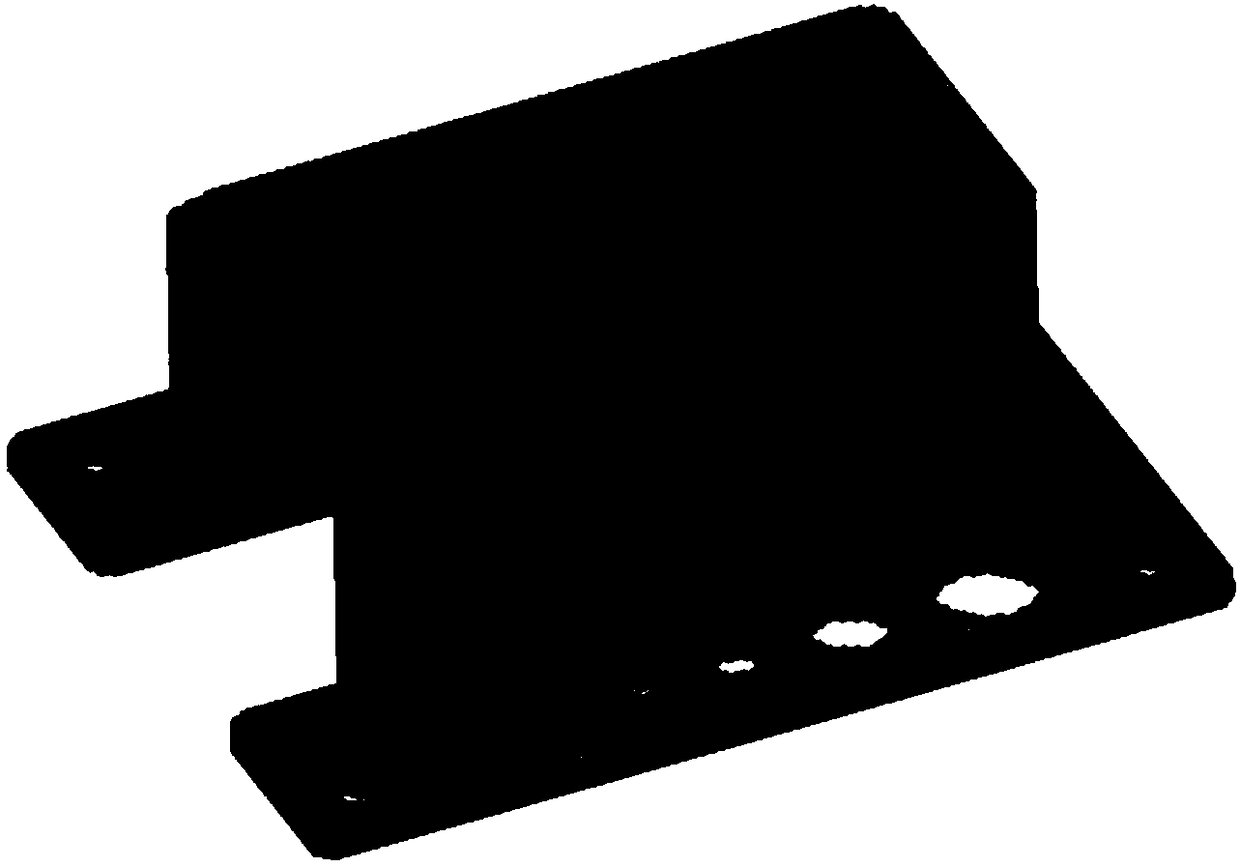

[0040] 1. Digitize and discretely process the 3D model of the printed part;

[0041] The 3D printing process is to complete the superposition of materials layer by layer, and finally stack them to form the entire print; the 3D model of the printed part is digitized and discrete, that is, the CAD model file is converted into a digital model with a slice layer; the size of the model is the same as the original The model error should be within the error required by the project; among them, the transformation of the whole slice layer thickness and the laser scanning contour route is the key to the simulation process.

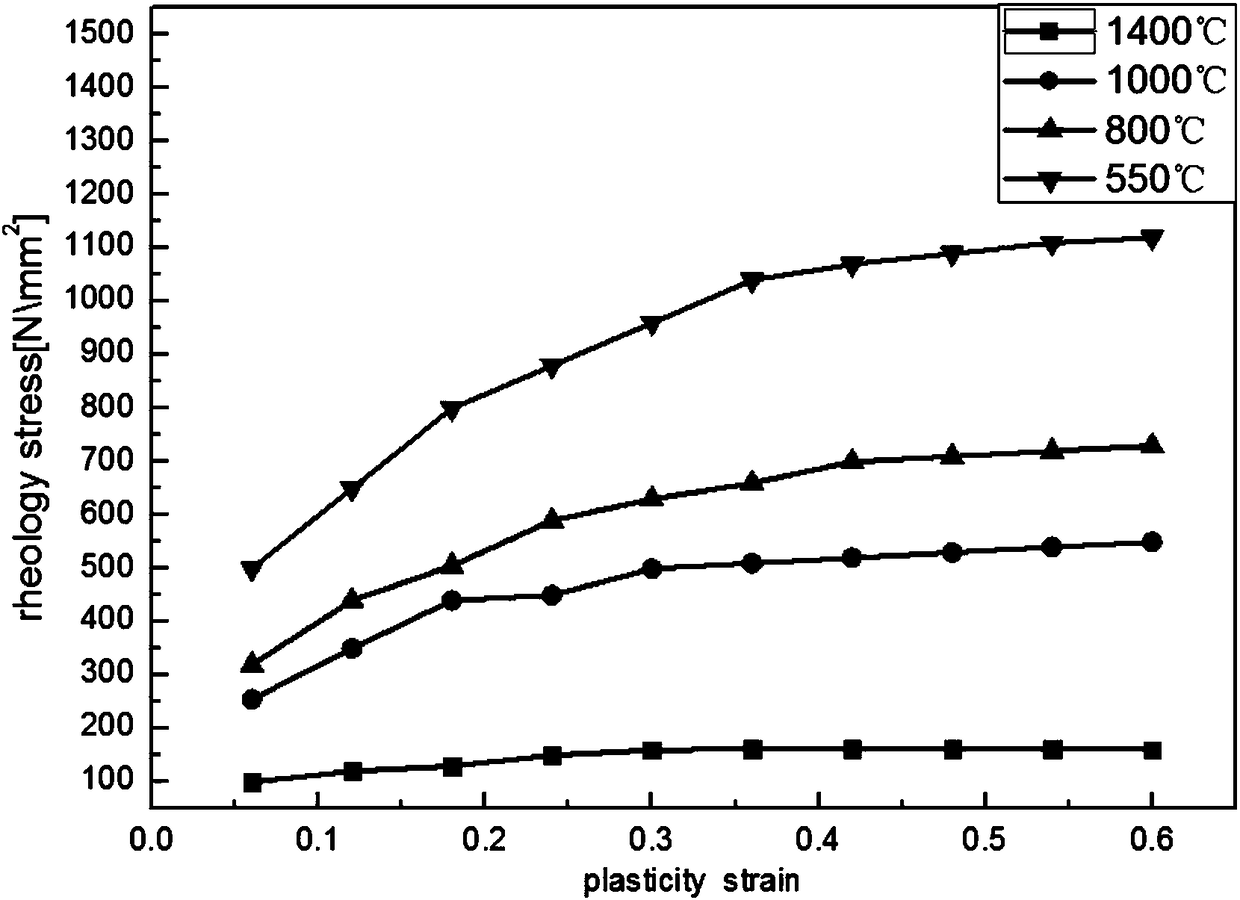

[0042] 2. Establishment of finite element model for additive manufacturing process simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com