A 3D printing process optimization method based on reinforcement learning

A 3D printing and process optimization technology, applied in additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problems of low laser absorption rate of aluminum alloy, few application scenarios, slow forming rate, etc., to improve 3D Print quality, flexible and convenient use, and the effect of preventing overheating of the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

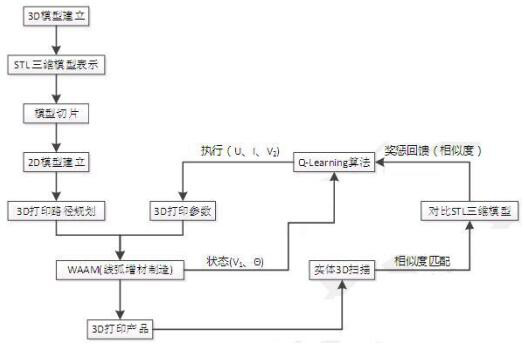

[0024] Example 1. A 3D printing process optimization method based on reinforcement learning, see figure 1 , follow the steps below:

[0025] a. Collect the printing parameters of several printed models to train the Q-learning model, obtain the optimal printing parameters of the printed models after training, and store the optimal printing parameters in the training model obtained after training;

[0026] b. Create a 3D model of the model to be printed, cut the 3D model into k slices, and build a 2D model of each slice;

[0027] c. Construct the 3D printing path planning of the model to be printed according to the 2D model of each slice;

[0028] d. Match the model to be printed with the printed model, and use the optimal printing parameters of the printed model with the highest matching degree with the model to be printed as the actual printing parameters of the model to be printed;

[0029] e. Input the 3D printing path planning in step c and the actual printing parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com