A method and realization device for improving the quality of FDM printing

A technology of forming quality and printing quality, applied in the field of improving FDM printing forming quality, method and realization device, can solve the problems of insufficient infiltration of fiber and resin, weak bonding strength between layers, low strength of composite materials, etc. The effect of improved adhesion, melt wettability, and improved print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

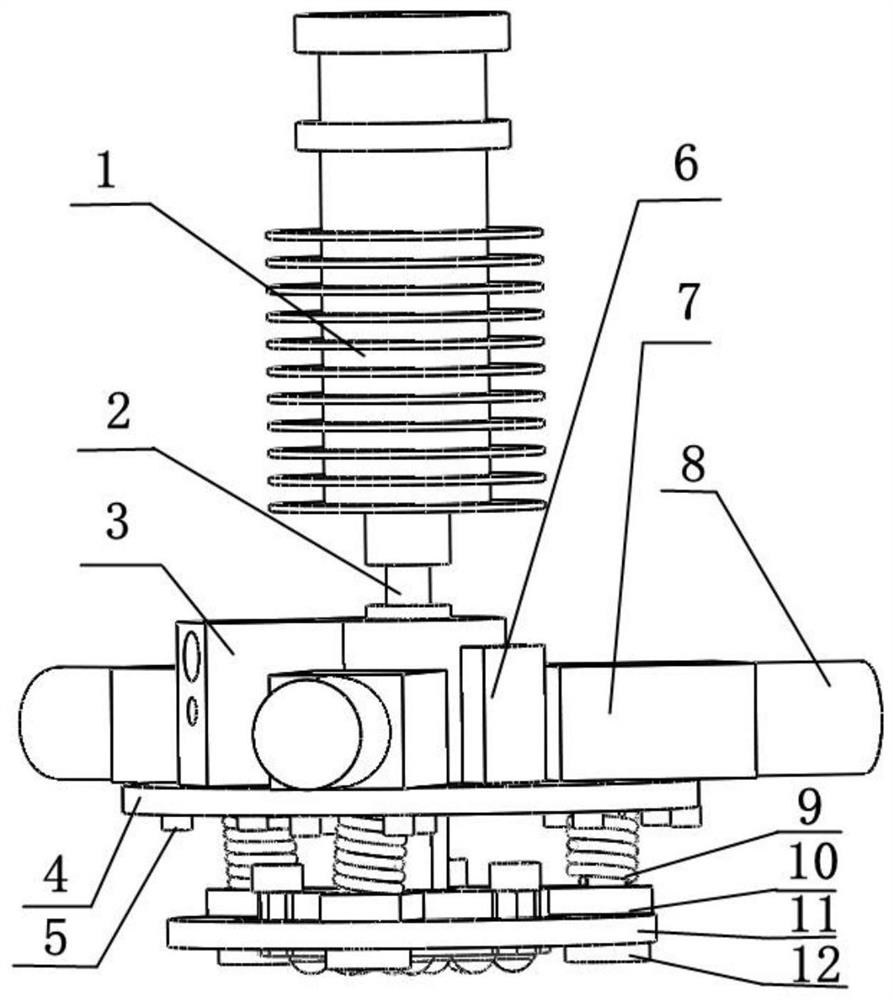

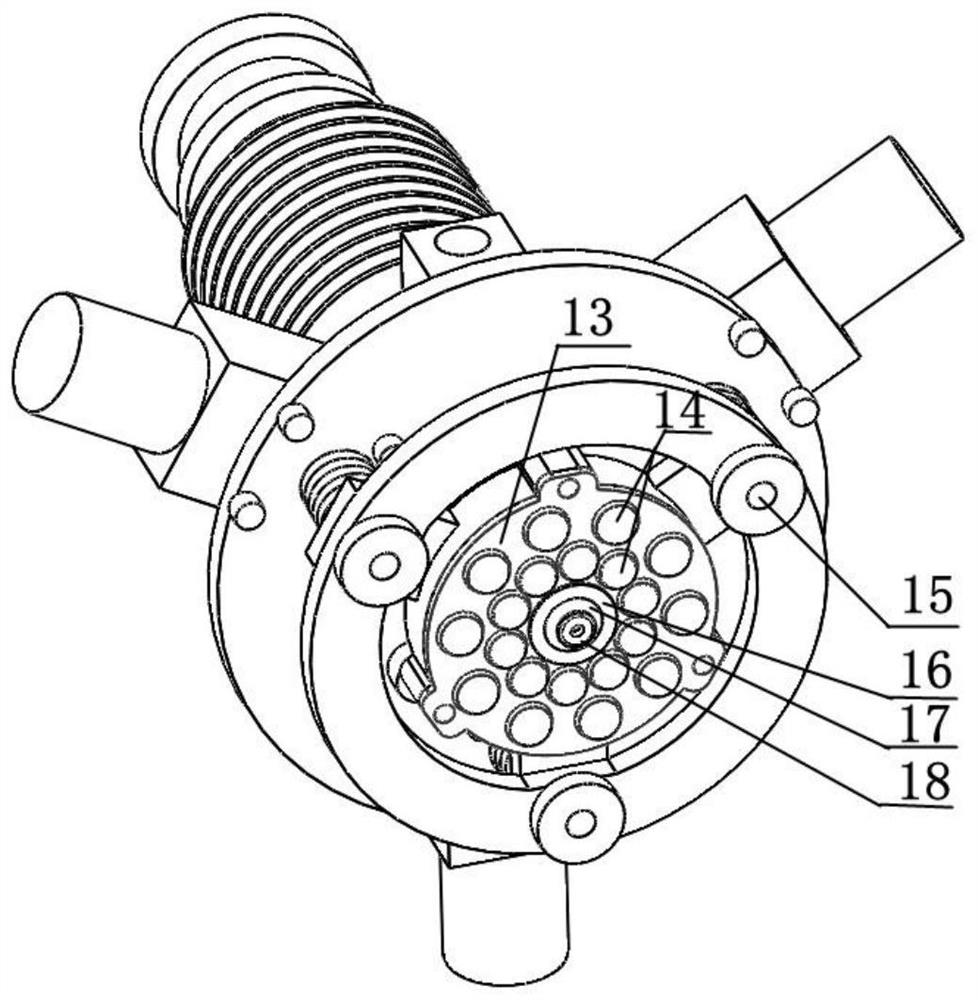

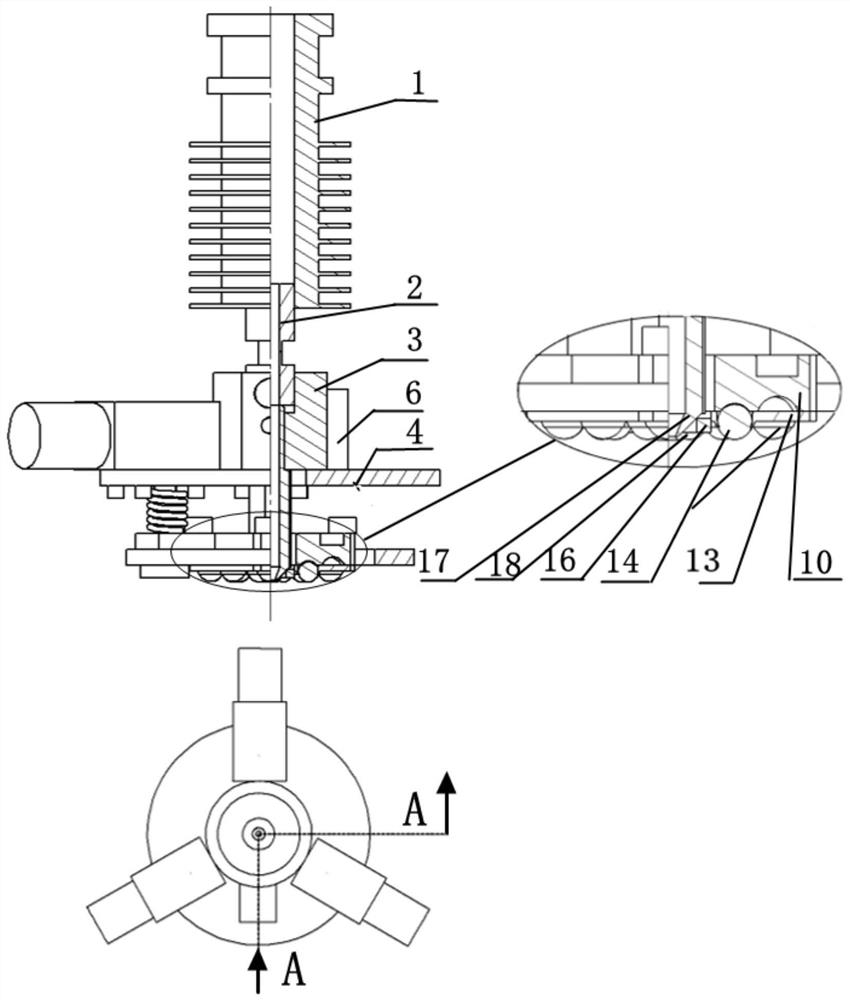

[0030] The invention provides a realization device for improving the quality of FDM printing. The device includes a vibration excitation mechanism, a compaction mechanism, a quality detection mechanism, and the like.

[0031] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS As follows, when printing starts, the fiber reinforced resin filament enters from the top of the heat dissipation pipe 1 , is driven by the wire feeding mechanism, passes through the throat 2 , reaches the heating block 3 for heating, and finally is extruded through the print head 17 . .

[0032] The vibration excitation module 6 generates vibration. The vibration source can be ultrasonic vibration or mechanical vibration. The vibration frequency and vibration power are adjusted according to the needs. The vibration is transmitted to the melting chamber of the heating block, which drives the fiber and the resin to vibrate together, thereby reducing the gap between the resin and the fiber. , so that the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com