Bogie of railway vehicle and axle box device of bogie

A rail vehicle and bogie technology, applied in the directions of bogie, axle box installation, transportation and packaging to prevent sliding friction, improve firmness and stability, and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

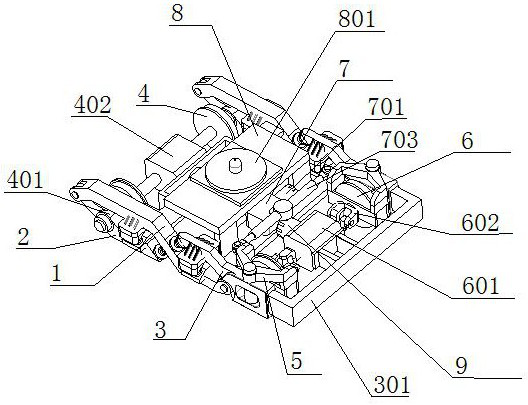

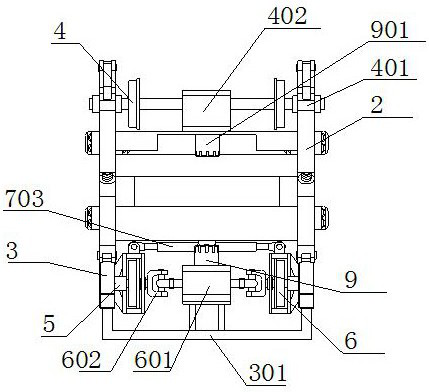

Image

Examples

Embodiment Construction

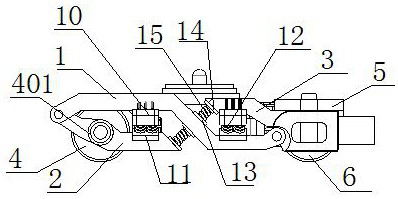

[0029] refer to image 3 One end of the second spring 15 is fixedly connected to one side of the first small spring seat 13, and the other end of the second spring 15 is fixedly connected to one side of the second small spring seat 14; the second spring 15 passes through the first small spring seat 13 and the second The small spring seats 14 are distributed on the upper and lower sides of the axis of the load-bearing beam 1. When the shock is damped, it can not only offset up and down, but also make the load-bearing beam 1 more evenly stressed through a three-point connection.

[0030] The working process and principle of the present invention: when in use, the bogie is installed on the bottom of the carriage, and the front wheel 4 and the rear wheel 6 are arranged between the rails. During the driving process, the bogie will encounter slight bumps. The beam 2 utilizes the first spring 12 and the second spring 15 between the front beam 2 and the load beam 1 for shock absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com