Hollow casting investment casting process

An investment casting and casting technology, which is applied in the field of hollow casting investment casting technology, can solve the problems such as the deviation of the cavity structure and size of the finished casting, affecting the molding quality of the finished casting, and the fracture of the mandrel, so as to improve the molding quality and ensure the internal hollow space. Cavity shape dimensional accuracy, effect of preventing breakage or cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

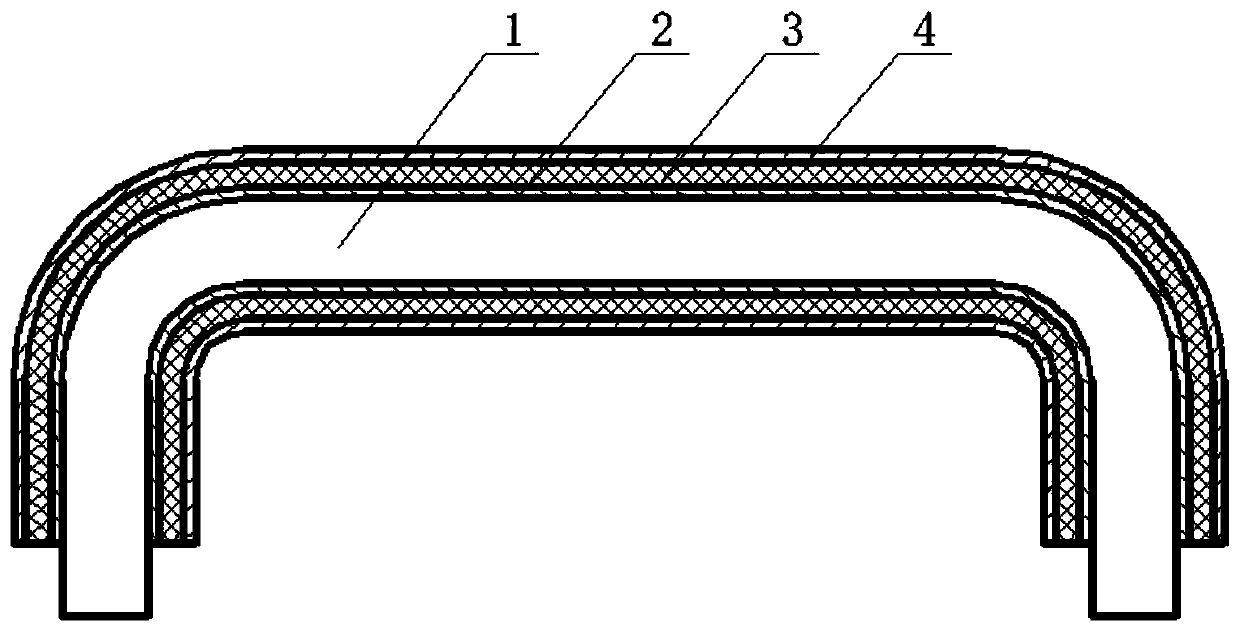

[0019] Such as figure 1 As shown, the present invention provides a hollow casting investment casting process, comprising the following steps:

[0020] Prepare the wax mold according to the shape of the pattern in the design drawing provided by the user, prepare the mandrel 1 according to the shape of the inner cavity of the design drawing provided by the user, and coat the reinforcement material 2 on the surface of the mandrel 1 in sequence from the inside to the outside , transition material 3 and protective material 4, and then insert the mandrel 1 into the wax mold to form a module, spray refractory sand on the surface of the module, and then roast the module to obtain a shell, and then pour and smelt it into the shell It is an alloy material in a liquid state, and a hollow casting is obtained after the alloy material is solidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com