Method for utilizing waste ceramics with 3D printing technology and product

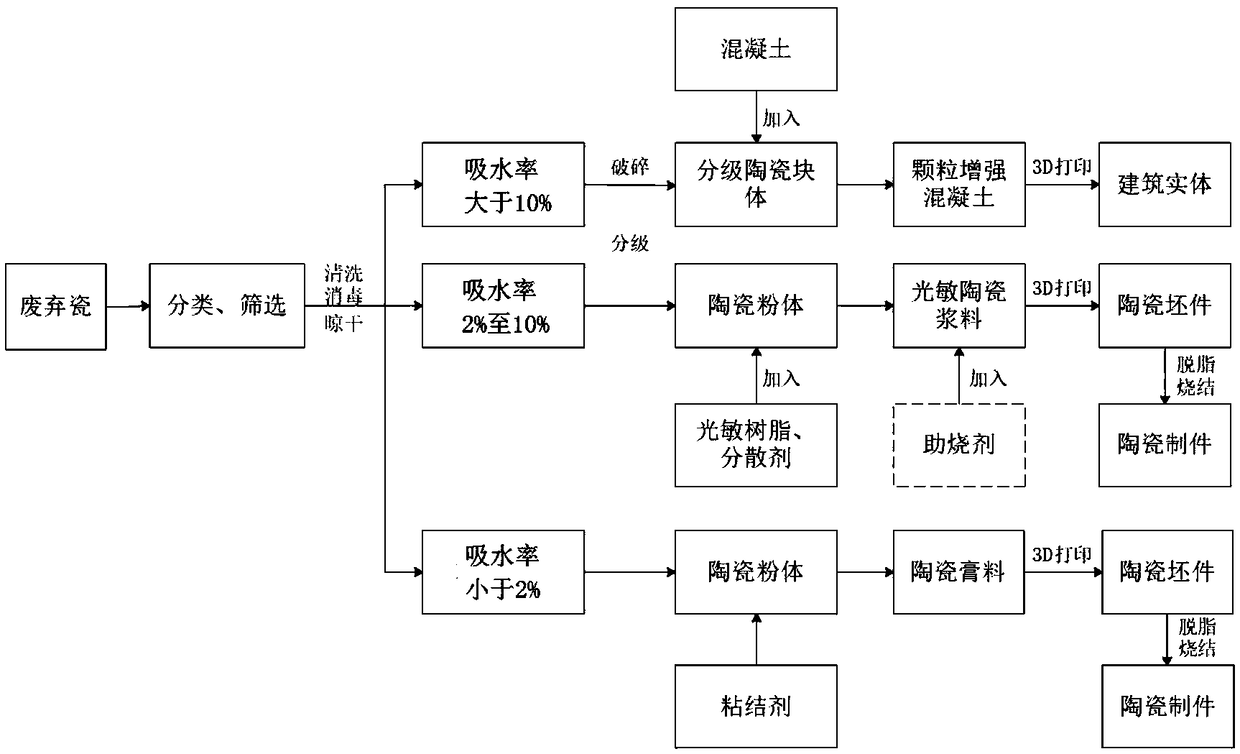

A technology of 3D printing and waste porcelain, which is applied in the field of using waste porcelain with 3D printing technology, can solve the problems of low utilization of waste porcelain, large difference in properties between waste porcelain and raw materials, and uncontrollable influence of products, so as to achieve low cost and prevent Cracks, the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) The recovered waste porcelain was crushed and sampled, and then the water absorption rate was measured using the TXY series digital display ceramic water absorption tester produced by Shanghai Precision Instrument Co., Ltd. according to its instructions. According to the water absorption rate below 2%, 2% to 10%, and above 10%, wash and dry them respectively.

[0046] 2) Take waste porcelain with a water absorption rate of more than 10%, crush it with a ball mill device at 80r / min, sieve and classify it with a mechanical vibrating screen device, and obtain characteristic diameters of 2-5mm, 5-10mm, and 10-20mm , 20-30mm ceramic particles;

[0047] 3) Mix the ceramic block obtained in step 2) according to the mass ratio of 4:3:2:1, add it into the concrete according to the ratio of 50wt% and stir evenly, and obtain a mixed concrete slurry containing evenly distributed ceramic blocks;

[0048] 4) Use extrusion-type architectural 3D printing equipment to extrude and accu...

Embodiment 2

[0051] 1) The waste porcelain classified in Example 1 with a water absorption rate of 2% to 10% is crushed, ground, and sieved using a ball mill device under the condition of 300r / min to obtain waste porcelain powder with a particle diameter of less than 100 μm;

[0052] 2) Add the waste porcelain powder obtained in step 1) to the acrylic resin according to the content of 60vol%, fully stir and grind to obtain a uniform and stable ceramic slurry, wherein 5wt% powder quality dispersant carboxymethyl should be added to the photosensitive resin base cellulose;

[0053] 3) The photosensitive ceramic slurry obtained in step 2) is subjected to light-curing 3D printing to obtain a ceramic vase blank with a diameter of 200mm, a height of 500mm, and a thickness of 5mm;

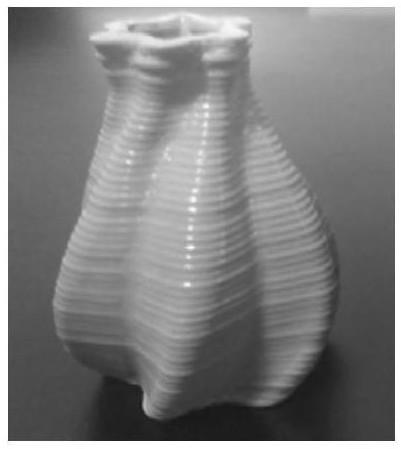

[0054] 4) The vase blank obtained in step 3) is degreased at 600°C for 6 hours in a kiln, then sintered at 1300°C for 2 hours, and then cooled with the furnace to obtain the final ceramic product, such as figure 2 sh...

Embodiment 3

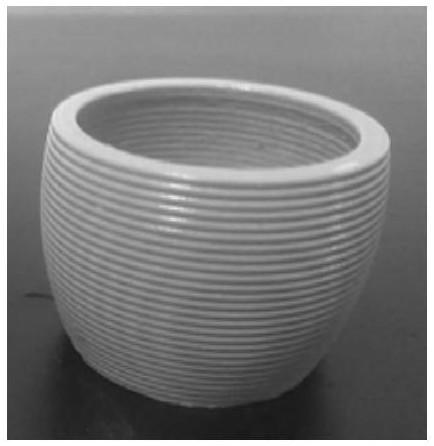

[0056] 1) The waste porcelain classified in Example 1 with a water absorption rate below 2% is crushed and ground by a ball mill under the condition of 400 r / min, and sieved with 150 mesh to obtain waste porcelain powder with a particle diameter of less than 100 μm;

[0057] 2) Add the waste porcelain powder obtained in step 1) to the epoxy resin according to the content of 60vol%, and mix in 2wt% glass powder, fully stir and grind to obtain a uniform and stable ceramic slurry, in which 3wt should be added to the photosensitive resin The dispersant oleic acid of % powder quality;

[0058] 3) The photosensitive ceramic slurry obtained in step 2) is subjected to light-curing 3D printing to obtain a ceramic jewelry blank;

[0059] 4) The ceramic jewelry blank obtained in step 3) was first degreased at 600° C. for 5 hours in a kiln, then sintered at 1100° C. for 3 hours, and then cooled with the furnace to obtain a final ceramic product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com