Composite materials

A technology of composite materials and alloys, applied in the direction of abrasives, polishing compositions containing abrasives, and other chemical processes, can solve the problems of poor rigidity of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Example 1 - Hardfacing Decals for Rock Breaker Faces

[0073] Hard Particle Component: Coarse-grained tungsten carbide, titanium carbide, zirconium carbide, zirconia, tantalum carbide, niobium carbide, hafnium carbide comprising from about 20% to about 97% by weight of the composite and having an average particle size of from about 5 microns to about 10,000 microns , chromium carbide, vanadium carbide and / or crushed cemented carbide.

[0074] Carrier Component: Fugitive polymer comprising from about 1% to about 20% by weight and providing complete burnout during initial heating of the applique.

[0075] Additive: From about 0% to about 50% by weight copper-based braze alloy.

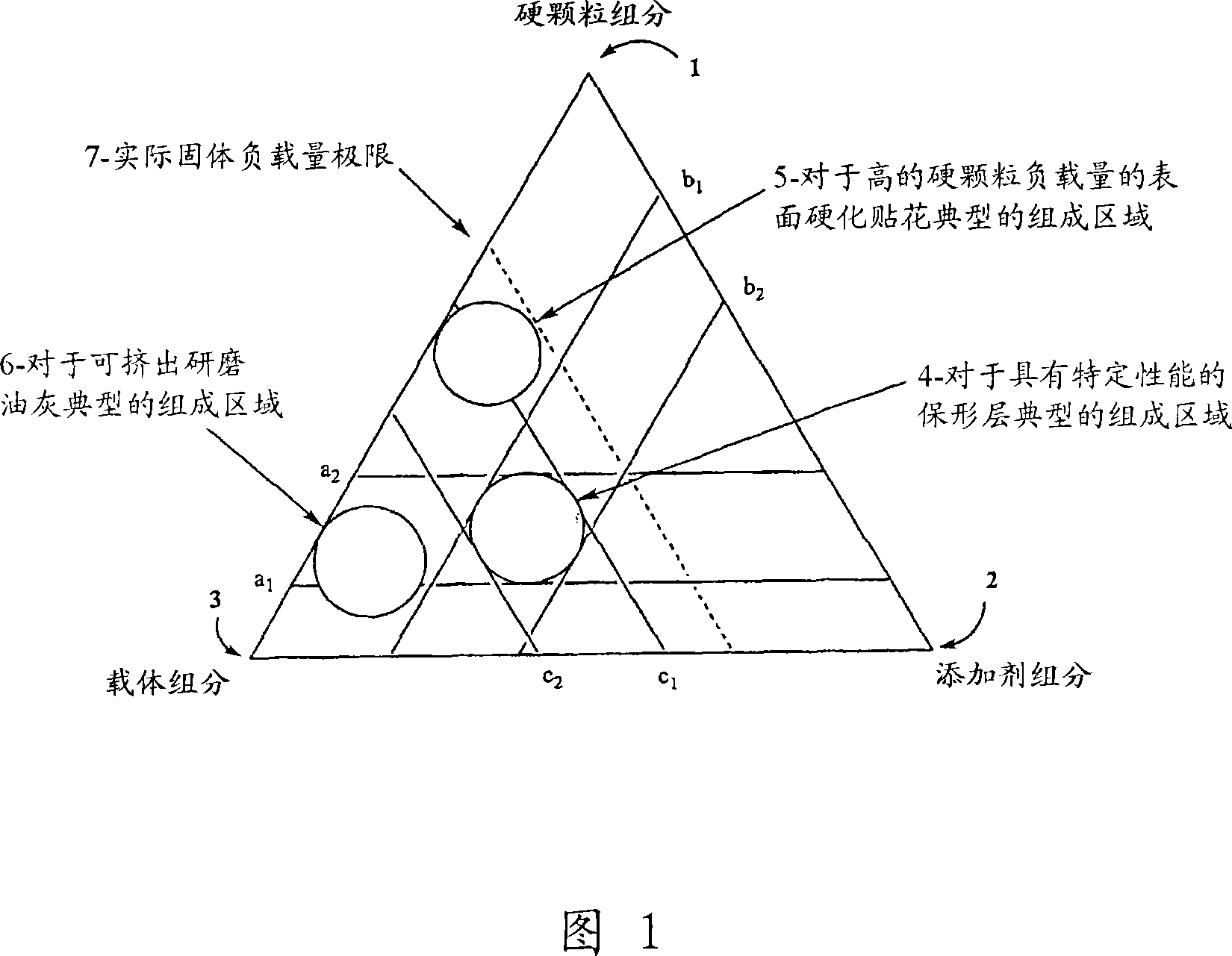

[0076] The density of the applique is preferably relatively high, at 2 g / cm due to the high loading of the hard particle component 3 to about 10g / cm 3 range and generally close to or exceed the calculated solid limit, as shown by the dashed line 7 in Fig. 1. The composite is in the form of a s...

Embodiment 2

[0077] The preparation of the wearing surface of embodiment 2-metalworking tool

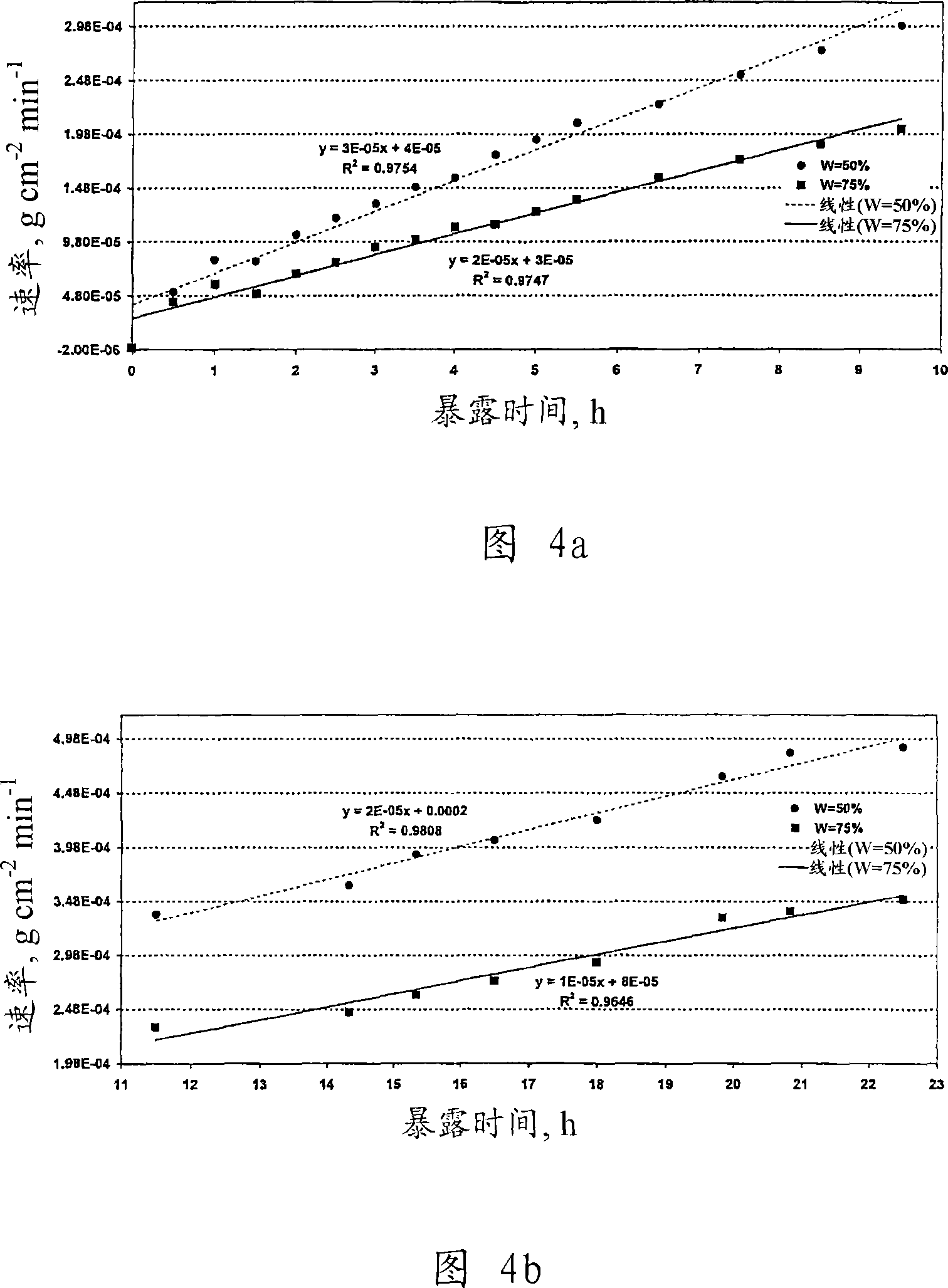

[0078] Hard Particle Component: Coarse grained tungsten carbide comprising from about 20% to about 97% by weight of the composite material and having an average particle size of from about 5 microns to about 10,000 microns.

[0079] Carrier Component: A fugitive elastomer comprising from about 1% to about 20% by weight and providing complete burnout during initial heating of the wear surface.

[0080] Additives: Transition metal based brazing alloys such as cobalt-, Ni-Co or Ni-Cu based brazing alloys or titanium alloys are typical, but more expensive Ag based brazing alloys may also be used. The transition metal-based braze alloy comprises from about 0% to about 50% by weight of the composite.

[0081] The density of the applique is preferably relatively high, at about 2 g / cm due to the high loading of the hard particle component 3 to about 10g / cm 3 range and generally close to or exceed the ...

Embodiment 3

[0082] Example 3 - Extrudable Grinding Putty

[0083] Hard Particle Component: Medium particle tungsten carbide comprising from about 0% to about 98% by weight and having an average particle size of from about 2 microns to about 5 microns.

[0084] Carrier Component: A polymer comprising from about 2% to about 50% by weight and providing a controlled and relatively constant viscosity.

[0085] Additives: 0% to about 30% by weight of stabilizers such as UV stabilizers and colorants for identification. Must be compatible with the specified carrier and generally readily available within the plastics industry.

[0086] Due to the presence of hard particles, the density of the putty is preferably medium, at about 2 g / cm 3 to approximately 8g / cm 3 within range. The putty is preferably extrudable at low pressures, ie, less than 689.5 kPa (100 psi), and is resistant to flow separation. The putty is also preferably non-corrosive, has low toxicity, and is easily recyclable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com