Bag bottom expanding rigid-flexible combined pile and construction method thereof

A technology of combined piles and pockets, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of uncontrollable bottom expansion effect and insufficient bearing performance of pile foundation, so as to improve the utilization rate of pile body and promote penetration range, the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Prefabrication and transportation of various pipe piles, cement-soil mixing or rotary grouting construction technology, bag manufacturing process, grouting pipe connection technology and grouting grout ratio are not repeated in this embodiment, and the focus is on the implementation of the structures involved in the present invention. Way.

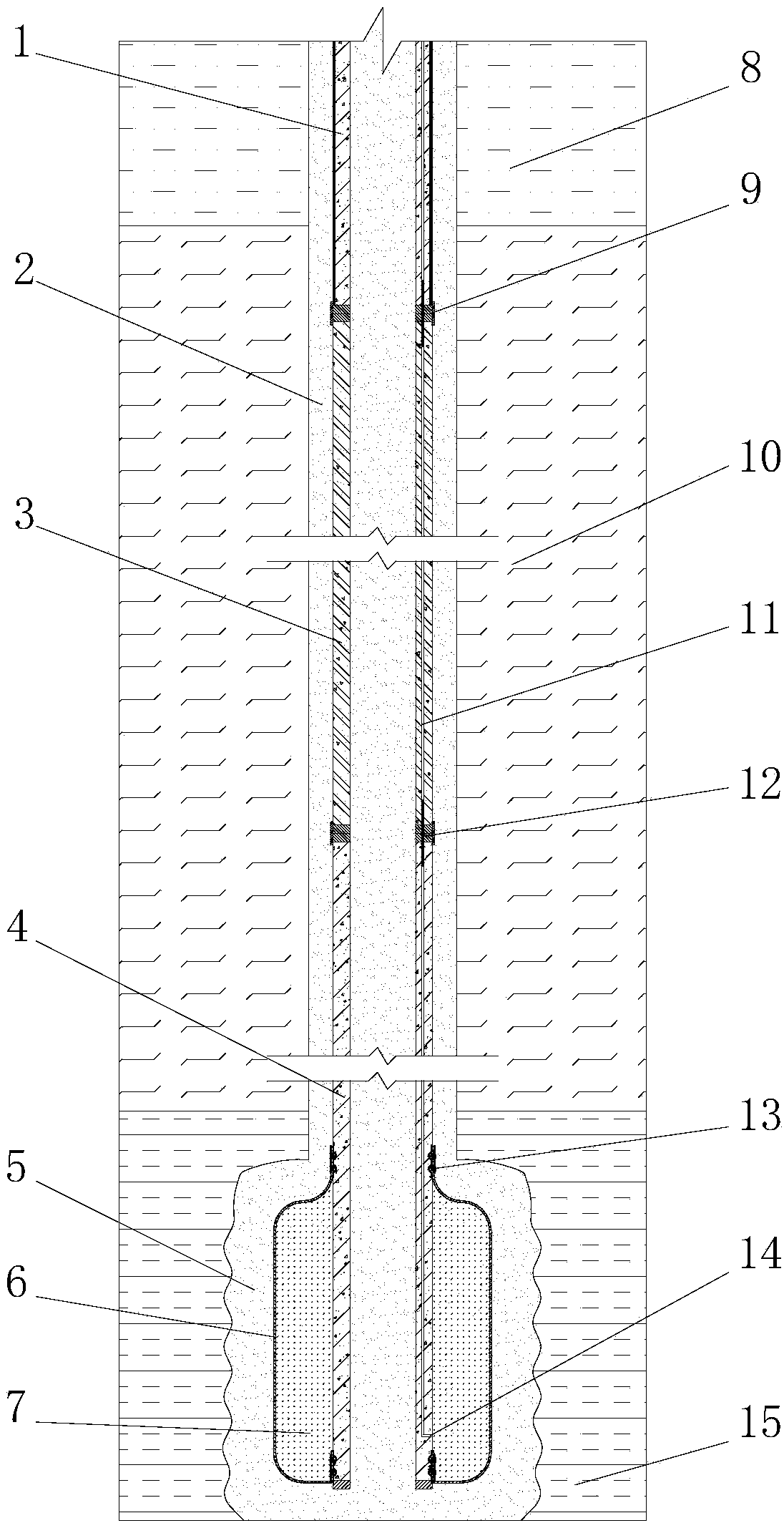

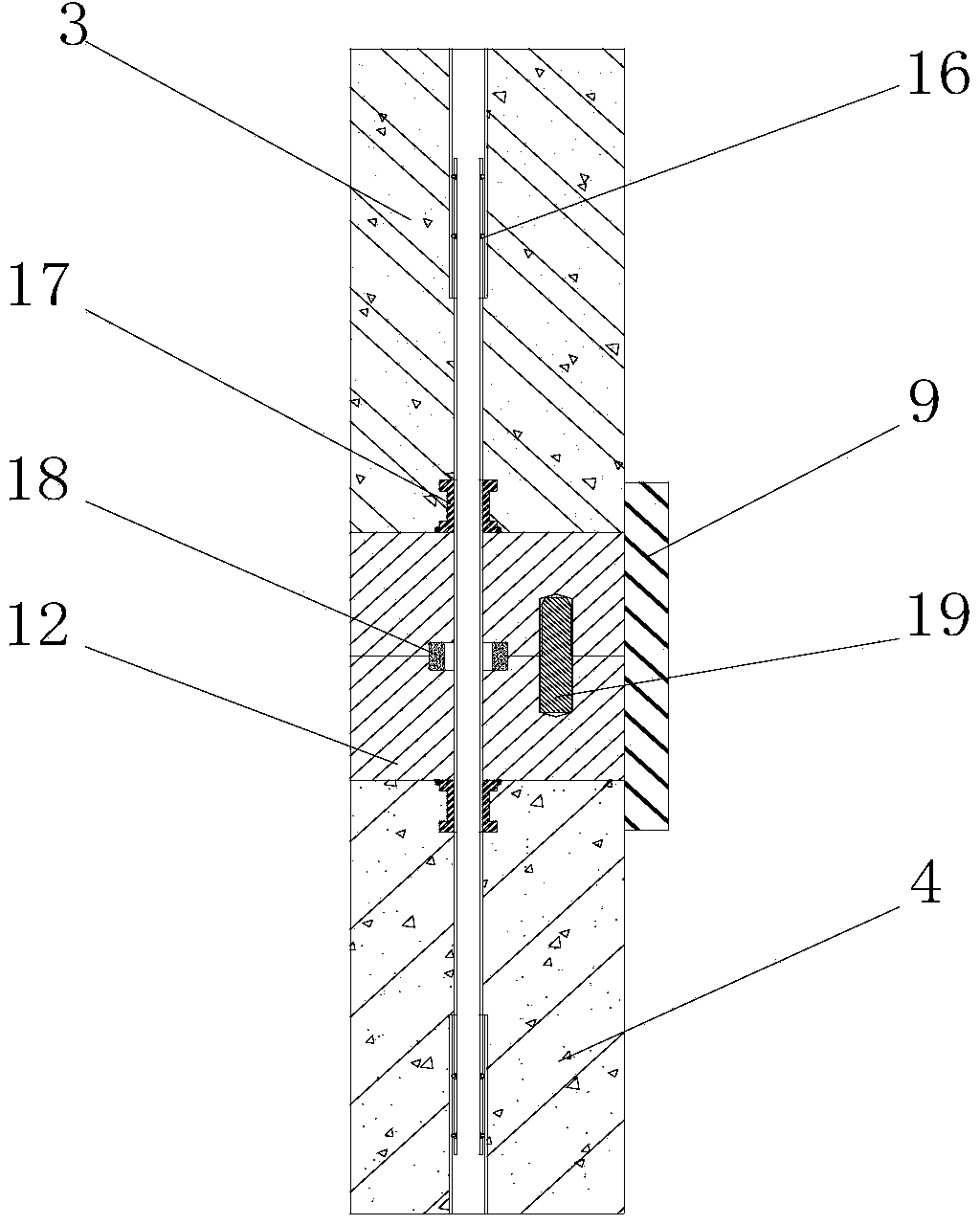

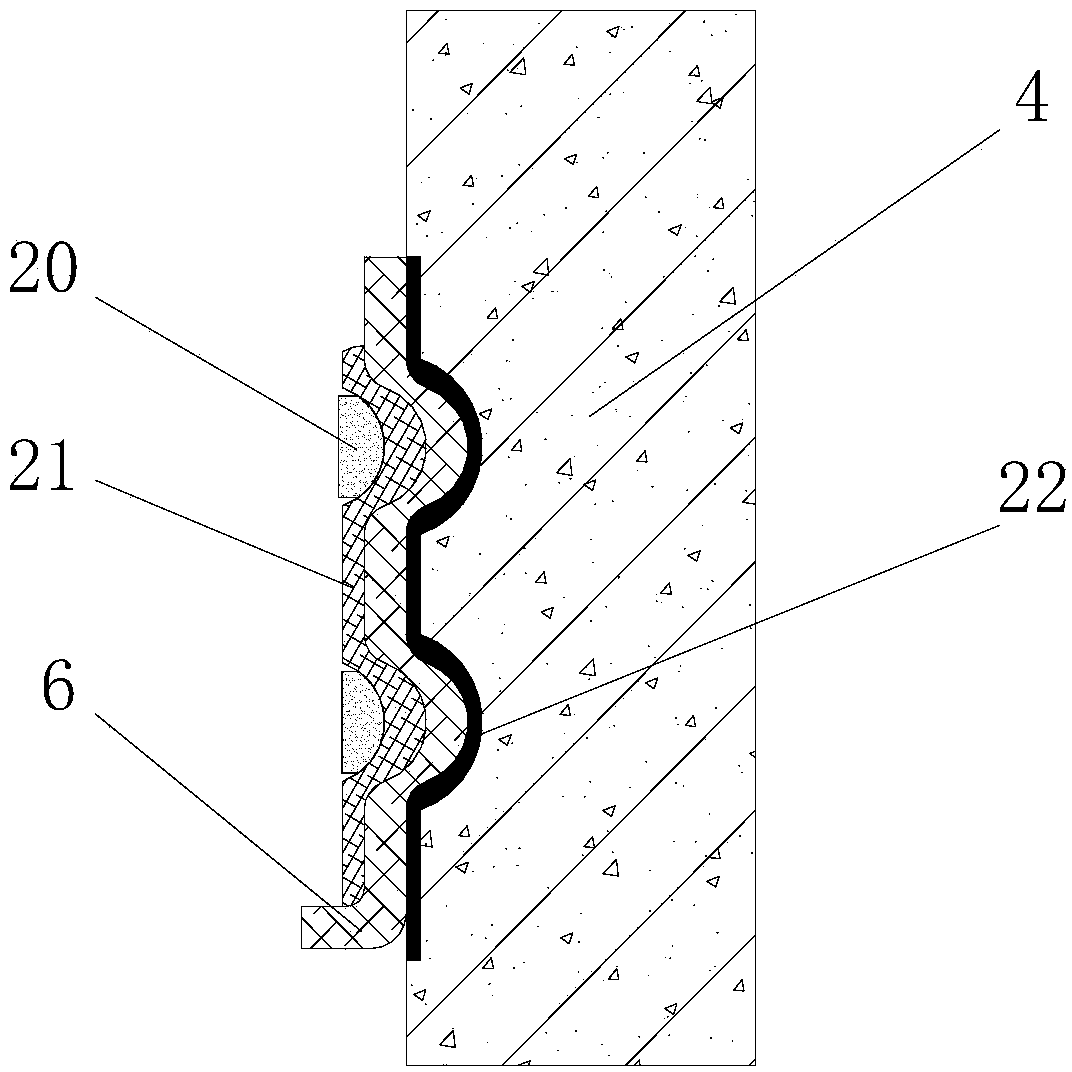

[0035] figure 1 It is a schematic diagram of a bag-bottomed rigid-flexible composite pile of the present invention; figure 2 It is a schematic diagram of the grouting channel at the pile connection place of the present invention; image 3 It is a schematic diagram of the arrangement of the expanded bottom bag in the present invention. refer to Figure 1~3 The rigid-flexible combined pile with pocket bottom expansion mainly includes: TSC pile 1, cement soil around the pile 2, PRC pile 3, PHC pile 4, pile end cement soil 5, and pile bottom expansion head 7.

[0036] Taking the cement-soil formed by the high-pressure rotary jet g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com