Fully fabricated self-expanding variable-diameter reinforcement cage with constrained sheath structure and application method of fully fabricated self-expanding variable-diameter reinforcement cage

A steel cage and variable diameter technology, which can be used in basic structure engineering, construction, sheet pile walls, etc., can solve problems such as cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

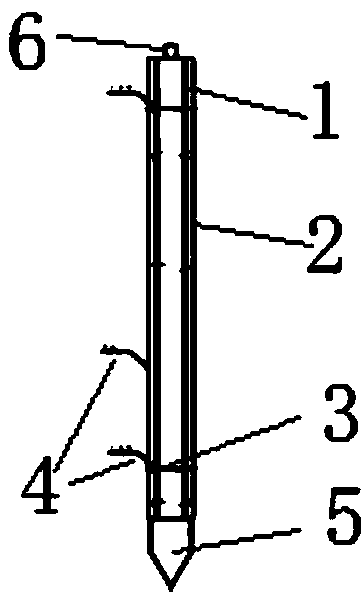

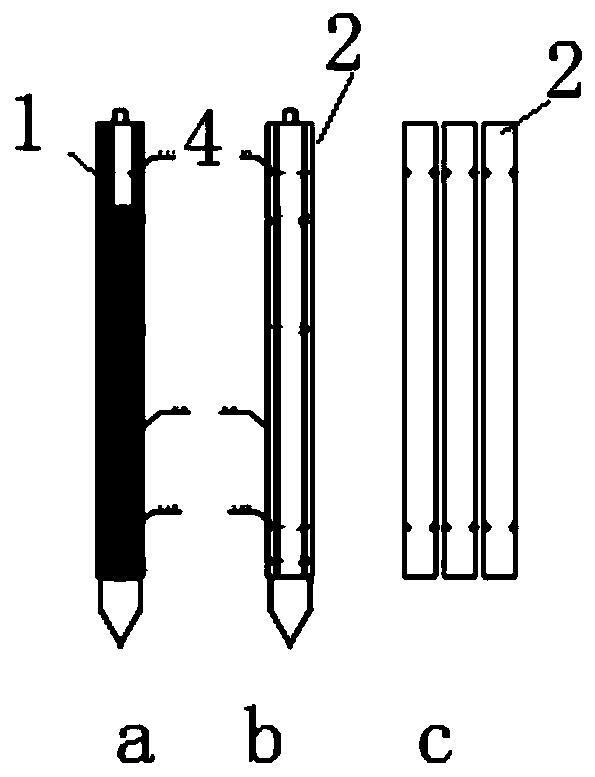

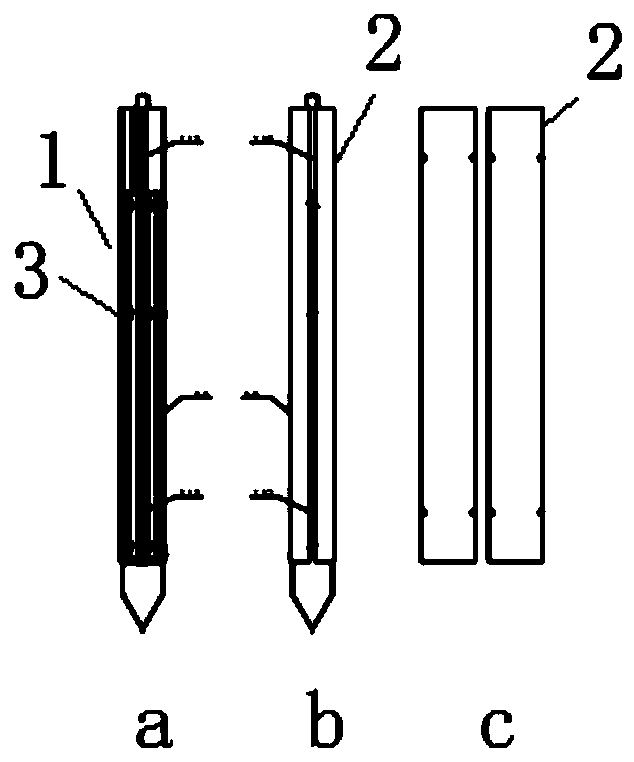

[0058]As shown in the figure, a fully-assembled self-expanding variable-diameter reinforcement cage with a constraining sheath structure of the present invention has two upper and lower ring-shaped fixers, that is, the flower piece and the active ribs 2, that is, the vertical ribs are not stretched and stretched. A structure, steel cage 1, restraining sheet 2, stirrup 3, restricting sheet enclosure 4, guide sleeve 5, main anchor rod 6; is provided with restricting sheet enclosure, and restricting sheet enclosure 4 can be elastic rope, Velcro , a thin rope with low strength or a switch that can be stretched by inner elasticity. After the ring or spiral stirrup is released, the vertical bar is stretched, and the elastic rope, velcro, low-strength string or the switch that can be stretched by the inner elastic are released. Figure 8-13 The lower end of the constraining sheet is tapered.

[0059] The applicant's expanded head pile bottom adopts a steel cage with a larger diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com