Variable-diameter reinforcement cage with simple structure and application method

A steel cage and variable diameter technology, which is applied in basic structure engineering, excavation, sheet pile walls, etc., to achieve the effect of concise and reliable structure, good integration, and speeding up the progress and application of the project.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

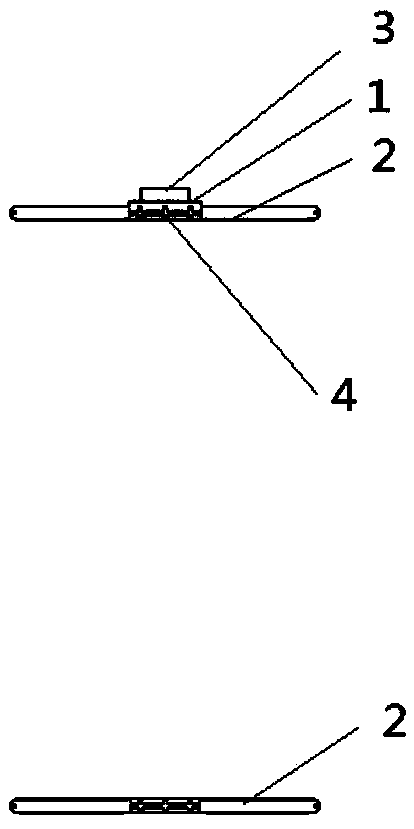

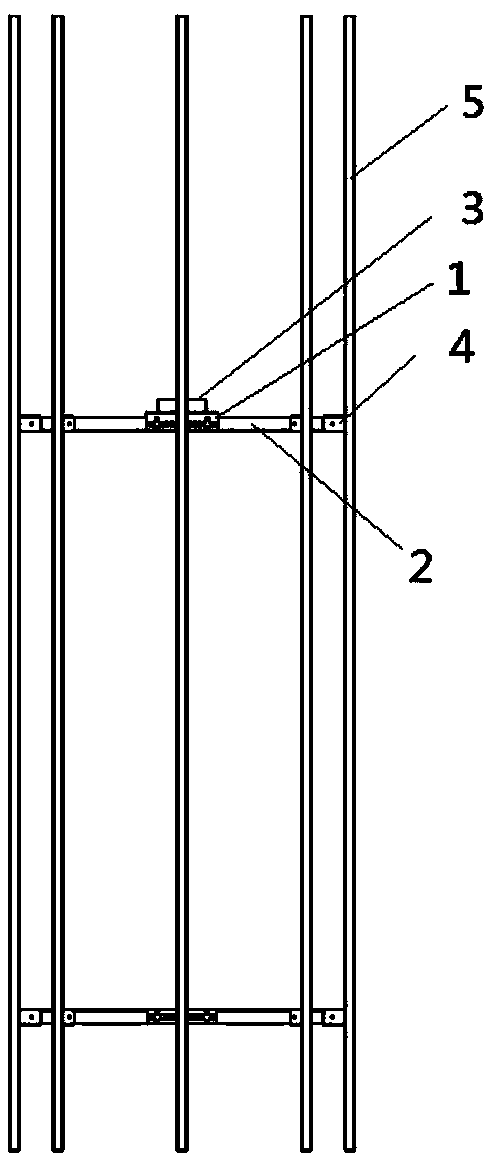

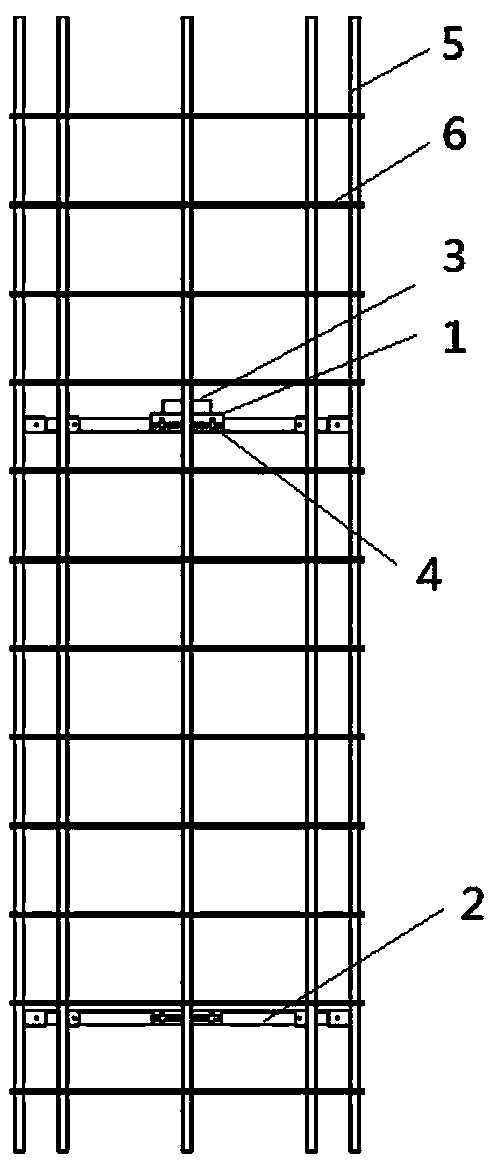

[0065] As shown in the figure, the ring-shaped fixer is the flower part 1, the flexible rib 2, the center hole of the flower part 3, the U-shaped connector 4, the vertical rib 5, the stirrup 6, the steel plate 7, the guide cap 8, the axial Rod 9, spring 11, limit pin 12. Bearing pin hole 4-1, spring is in the ring shape limiter 12-1 of axial rod.

[0066] The main reinforcement of the steel cage is provided, and the ring-shaped fixer (or an axial rod) is set on the main reinforcement of the central shaft hole of the ring-shaped fixer. The displacement action device of the shape fixer: a spring 11 that can be compressed and released is sleeved on the main rib or the axial rod, and the spring is limited by the limiter 12-1 that is sleeved on the axial rod; Pneumatic or hydraulic devices are used to stretch the active ribs connected with the ring-shaped fixer to release the vertical ribs and ring-shaped or spiral-shaped stirrups. The diameter of the main reinforcement can reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com