Composite type combined piles and construction method thereof

A combined pile and composite technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of limited pile length, fluctuation of pile body quality, and high construction energy consumption, so as to avoid the pre-compression stress of the pile body. Changes, the effect of improving the horizontal bearing capacity of the pile body and the improvement of the pile body's pull-out resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The composite combined pile and its construction method of the present invention will be described in conjunction with the accompanying drawings and embodiments.

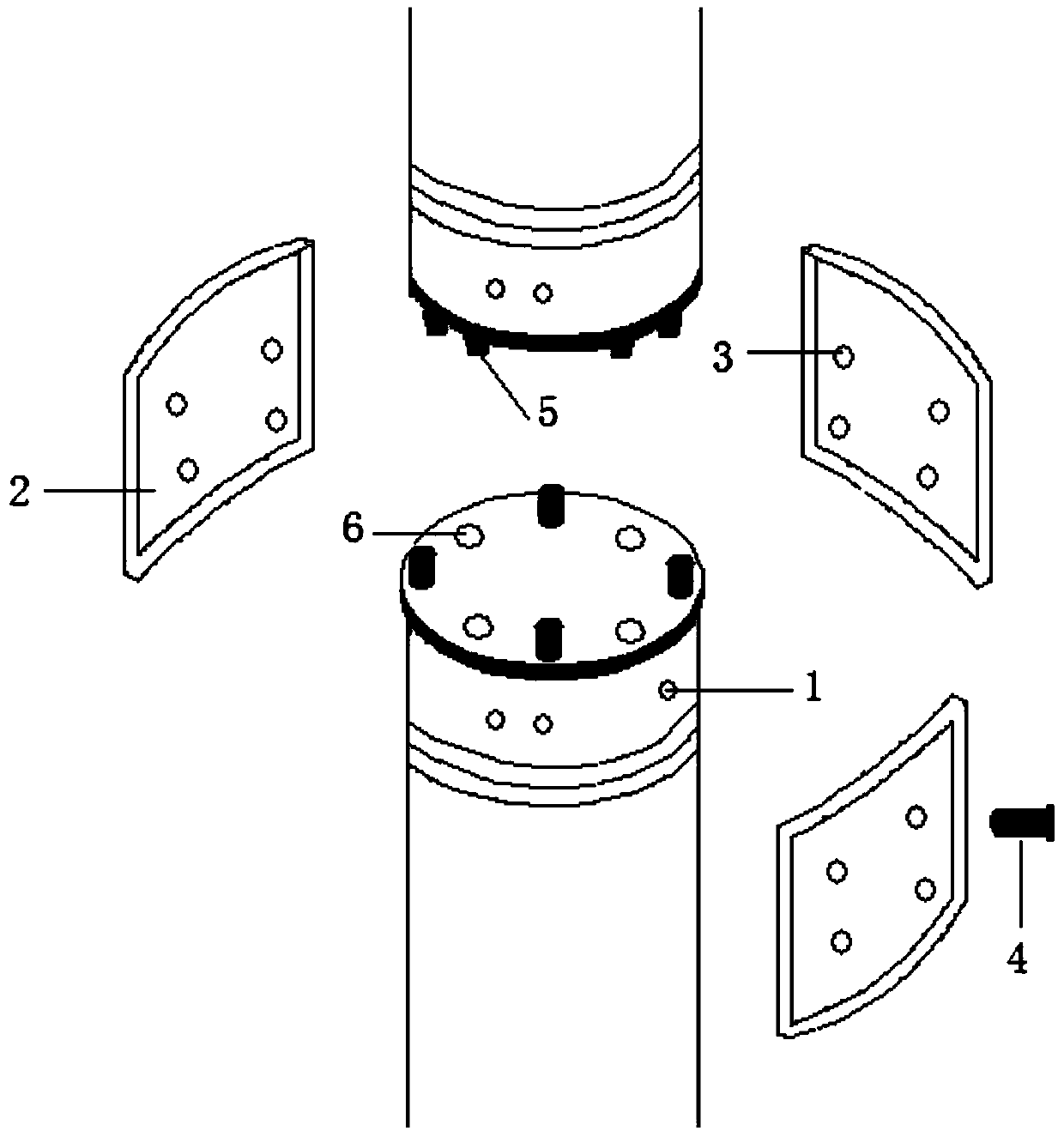

[0021] Such as figure 1 , 2 , Shown in 2-1, the composite composite pile of the present invention, described composite composite pile comprises a plurality of rectangular pile combinations, a plurality of non-prestressed pipe piles, a square pile combination, and a plurality of bamboo-shaped pipe piles, square piles Combination, the combination of multiple prestressed pipe piles to form a variety of composite composite piles of different pile types, and the connection method of each of the upper and lower piles of each composite composite pile is mechanical connection.

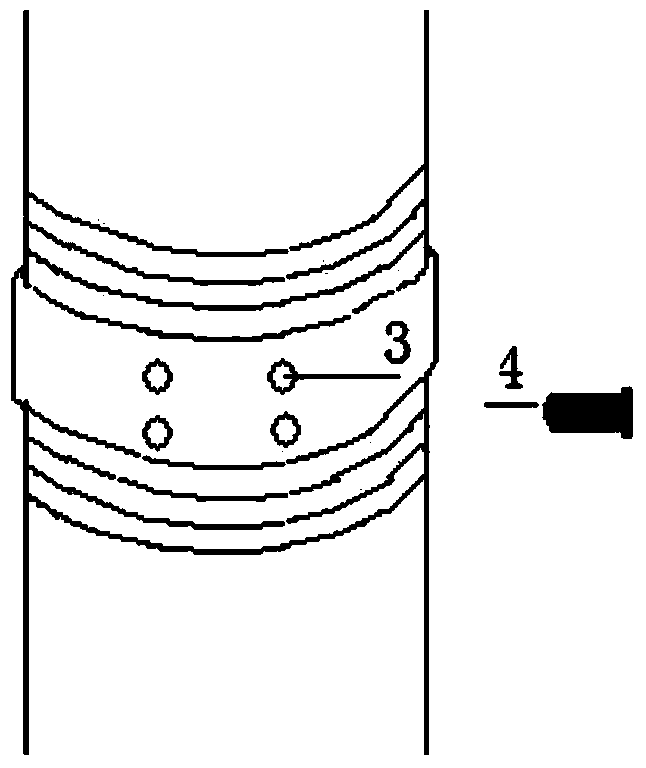

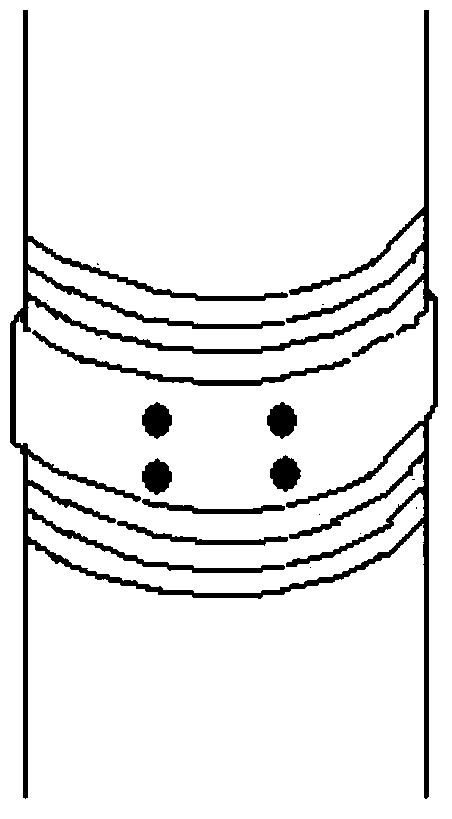

[0022] The mechanical connection structure of each of the upper and lower piles is that the outer circumference of the pile ends of each of the upper and lower piles is provided with evenly arranged reserved thread button holes 1, and the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com