Nail type cement soil stirring pile operation method

A technology of cement-soil mixing pile and operation method, which is applied in sheet pile wall, building, foundation structure engineering and other directions, can solve the problem that the strength of hard shell soil itself cannot be fully utilized, and affects the large-scale popularization and application of cement-soil mixing pile. , the difficulty of coordinating the sharing of piles and soil, etc., to avoid uneven settlement, easy to popularize, and save project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

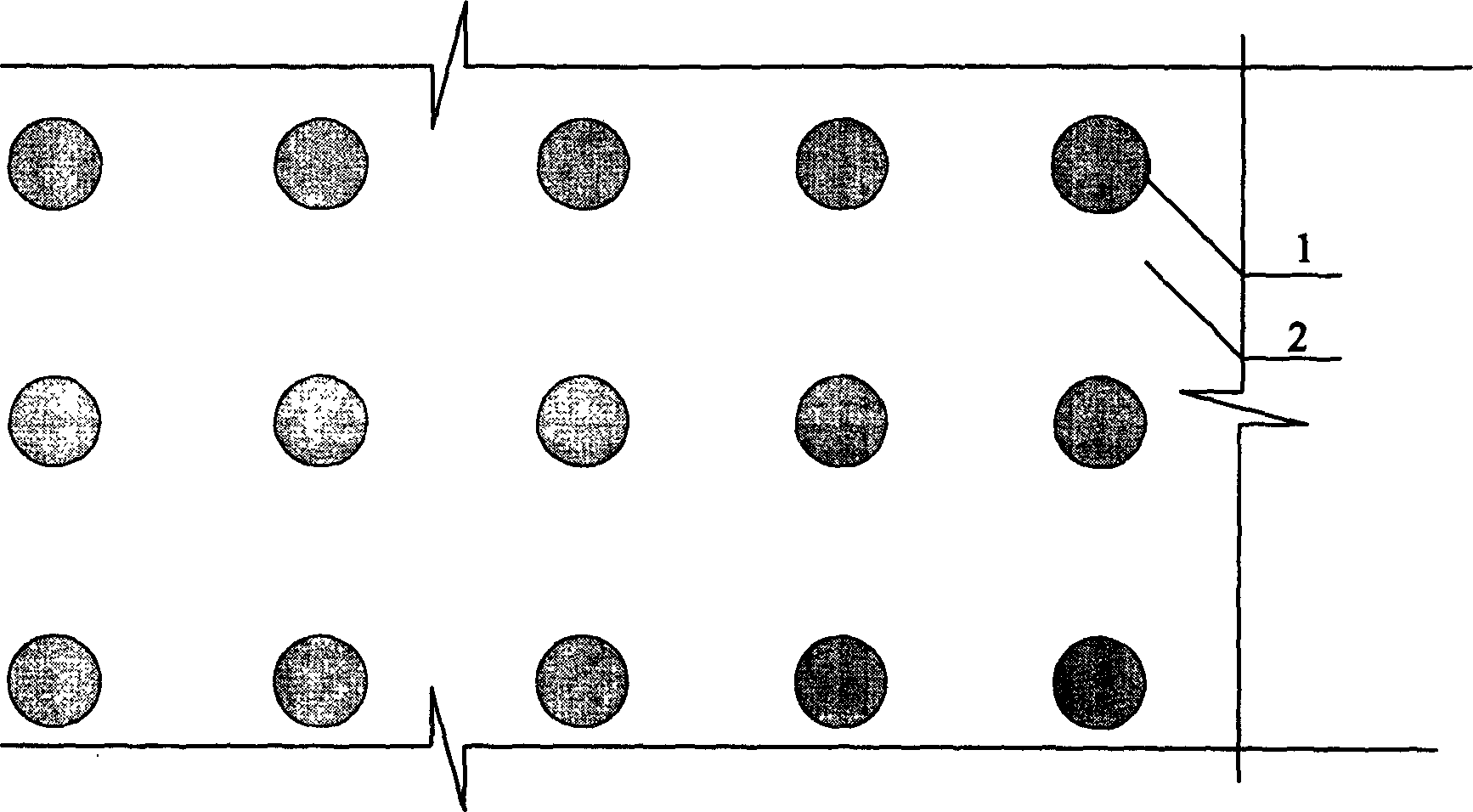

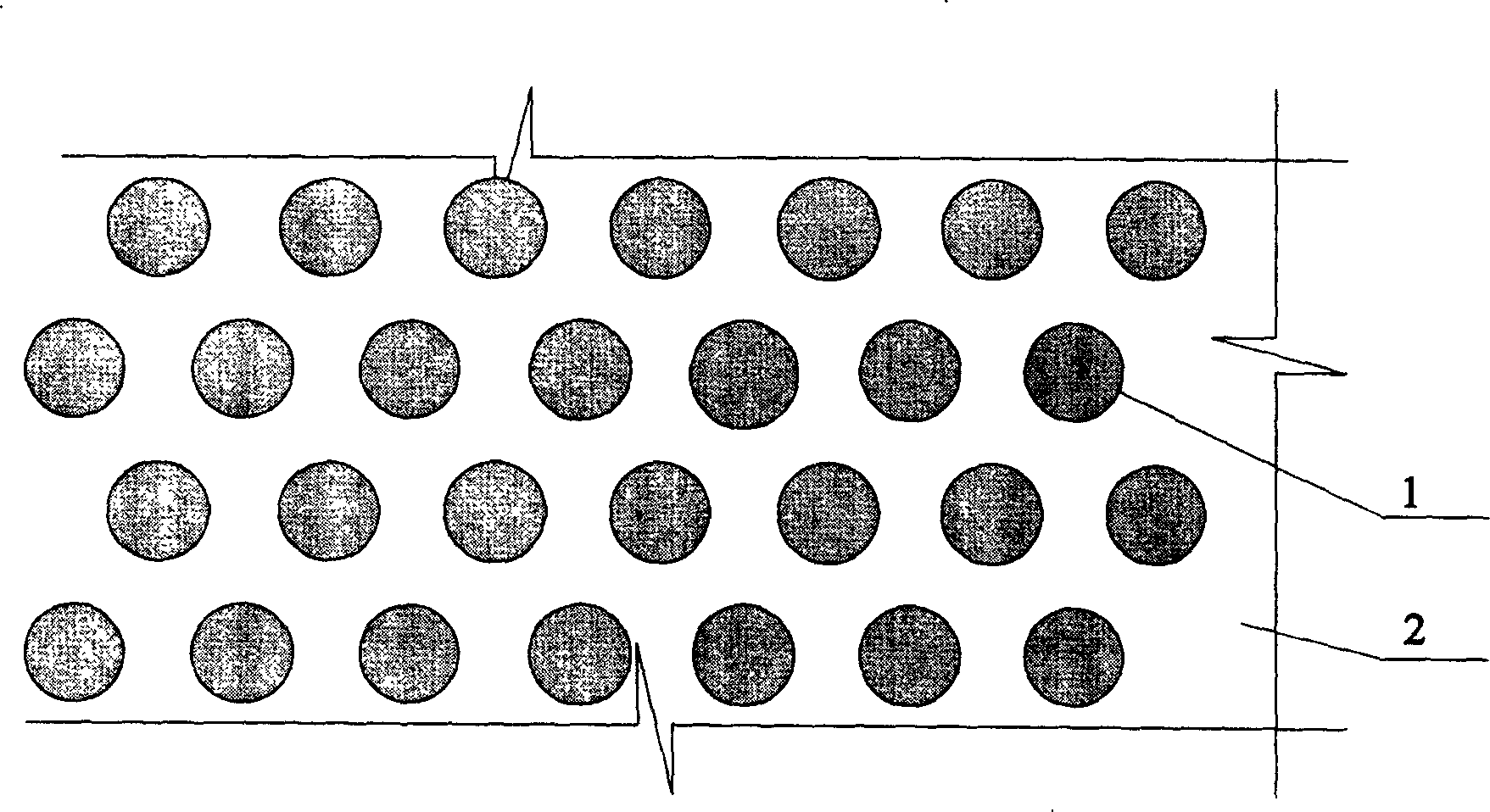

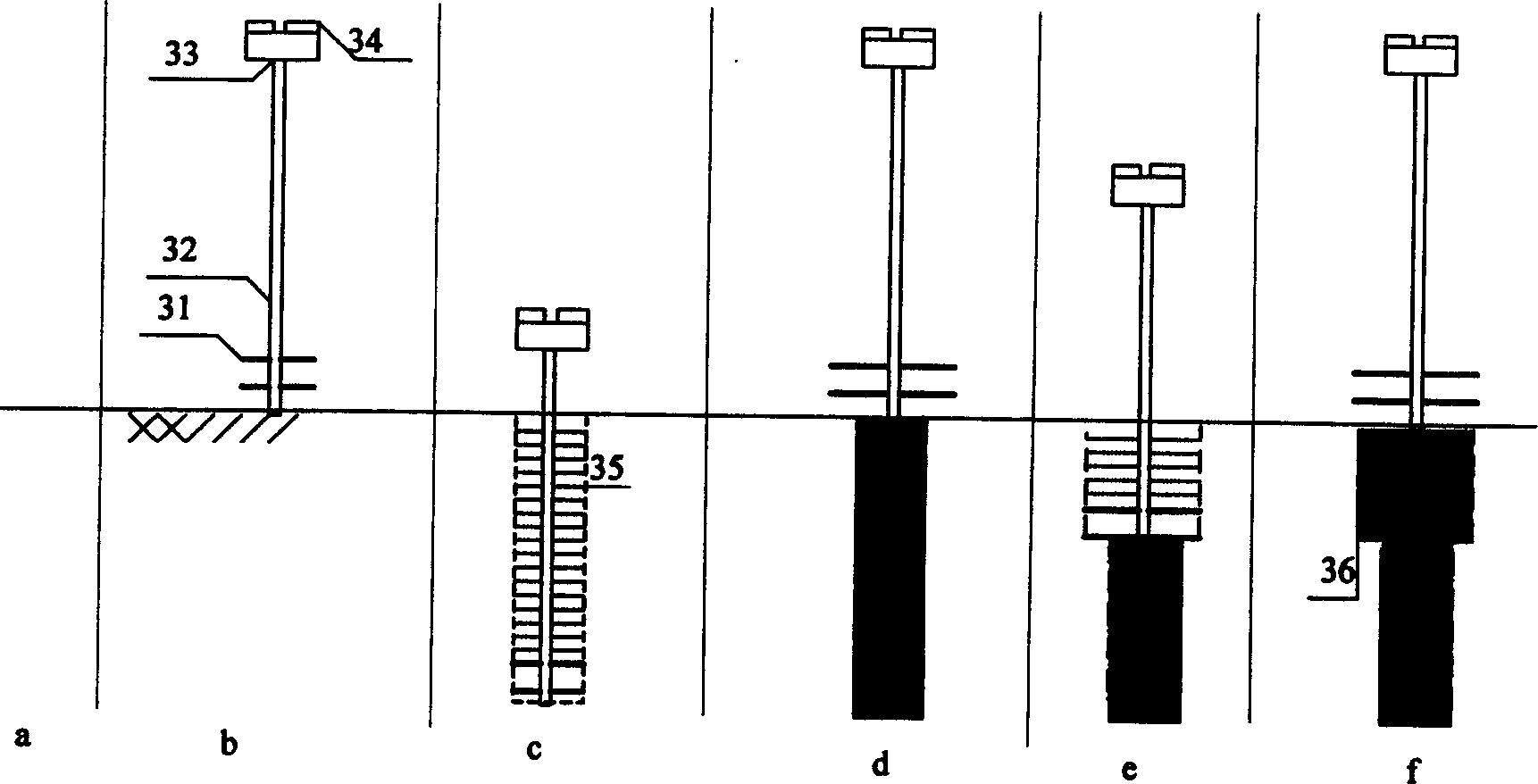

[0028] The embodiment is a certain construction section, 8 wet-sprayed piles for on-site construction test, the pile length is 10 meters, the ash mixing ratio is 15%, the pile diameter is 500 mm, the pile diameter of the enlarged part of the upper part is 900 mm, and the variable cross-section positions are respectively located at the upper part of the pile 3 meters and 5 meters away.

[0029] (1) Leveling the site;

[0030] (2) The pile positions of the test piles are arranged in a square shape;

[0031] (3) Positioning of the mixer: the crane suspends the mixer to the designated pile position and aligns it;

[0032] (4) Stirring and sinking: Start the mixer, make the mixer cut the soil down along the guide frame, the pile is 500mm long, turn on the slurry pump to spray cement slurry to the soil, the blades rotate forward and reverse at the same time to stir the cement soil, and the mixer continues to sink until 10 meters depth;

[0033] (5) Lifting and mixing: the mixer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com