Z-shaped steel plate combined shear wall with stiffening ribs arranged in staggered mode

A combined shear wall, staggered arrangement technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of small mechanical bite force, high construction cost, low out-of-plane stiffness, etc., to increase the mechanical bite force and improve the overall performance. , to ensure the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

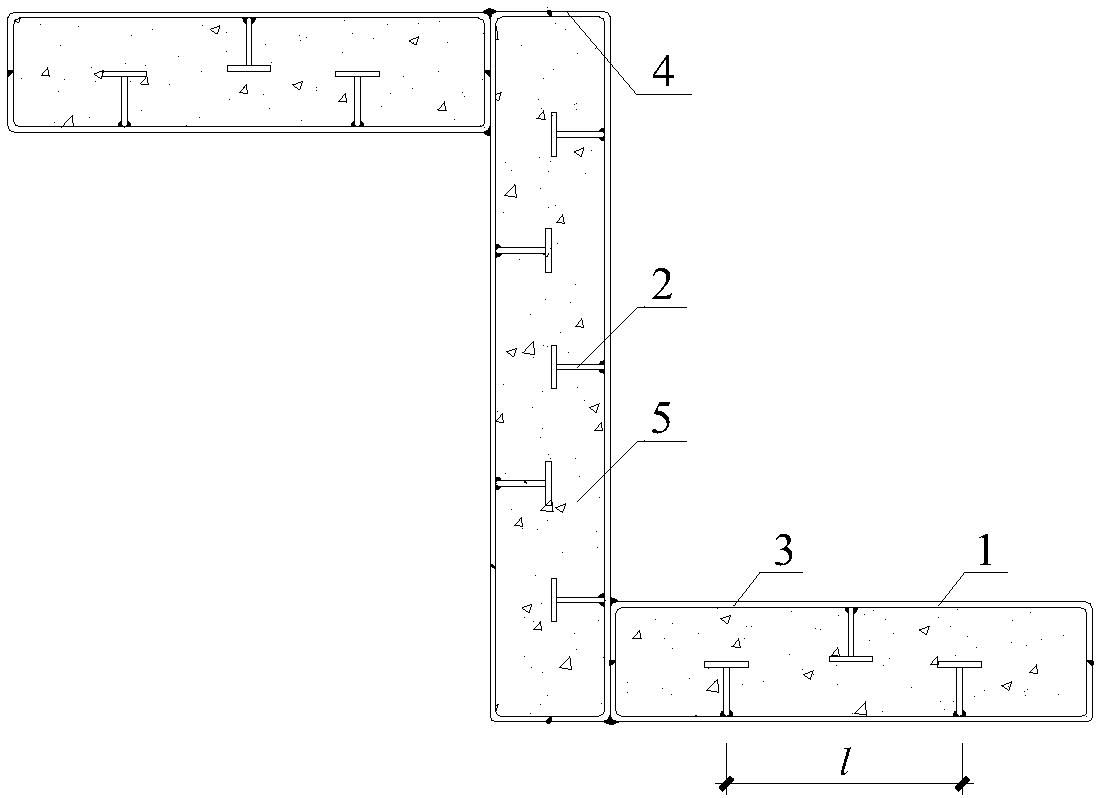

[0012] A Z-shaped steel plate composite shear wall with staggered stiffeners, including a channel member 1, a stiffener 2, and concrete 5, and T-shaped stiffeners 2 are arranged on the web 3 of the channel member according to the design requirements to form a ribbed channel The distance between adjacent stiffeners 2 is l, and the value of l is 2 to 4 times the height of the flange 4 of the channel-shaped steel plate; design another channel-shaped member 1, T-shaped stiffener 2 and the first channel-shaped The members 1 are arranged in a staggered manner, and the flanges 4 of the two grooved members are welded to form a rectangular cavity; the short sides of the two rectangular cavities are respectively welded to the two ends of the long side of the other rectangular cavity to form a Z-shaped cavity; Pour concrete 5 in the cavity.

Embodiment 2

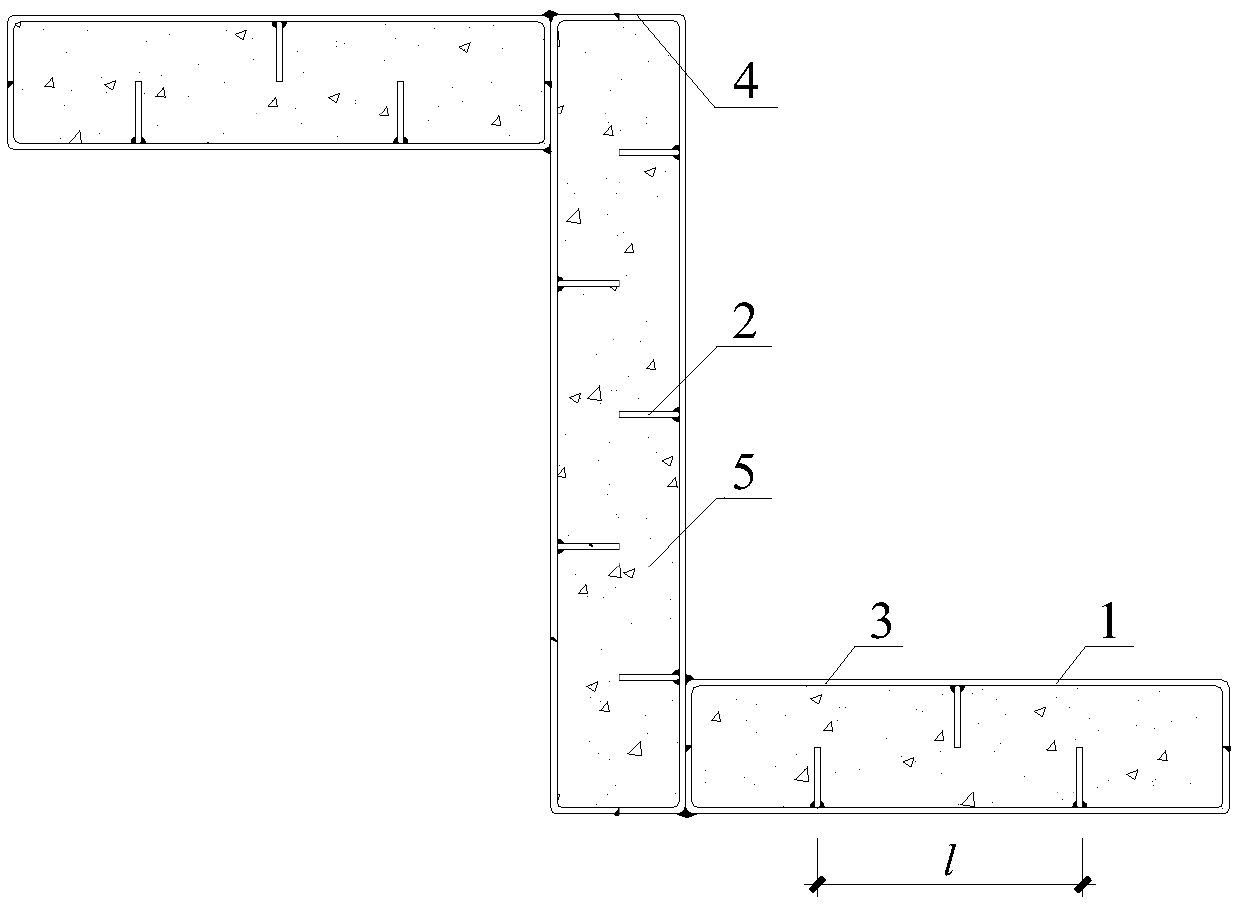

[0014] The difference from Example 1 is that the form of the stiffener is Type I.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com