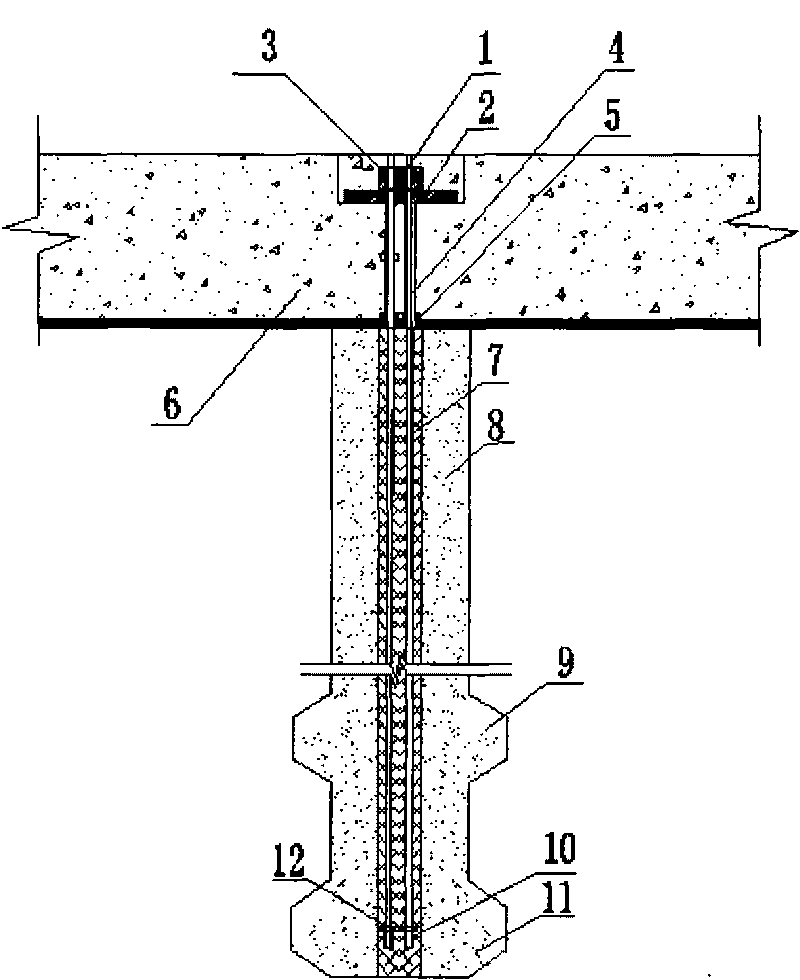

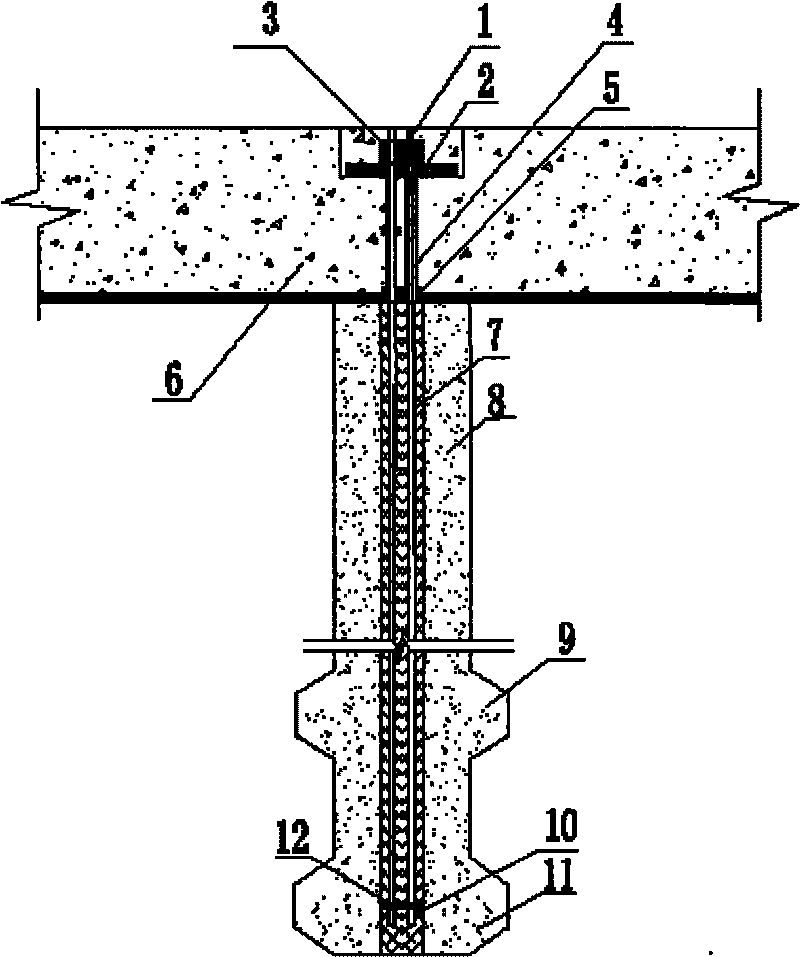

Soil cement expanding uplift pile

An uplift pile and cement-soil technology, applied in sheet pile wall, construction, infrastructure engineering, etc., can solve the problems of cost, quality and long construction period, high cost of uplift pile, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] (1) Measurement and positioning;

[0023] (2) Install the cement-soil rotary grouting pile forming machine, and hang the tensioned tendon material and anchor head at the drill bit;

[0024] (3) According to the designed pile diameter, adjust the construction parameters, and break the weak soil by means of rotary spraying or stirring rotary spraying;

[0025] (4) Spray cement slurry through the drill shaft hollow pipe and rotary nozzle;

[0026] (5) Pushing the drill pipe while stirring and injecting;

[0027] (6) When reaching the position where the diameter needs to be expanded, change the jet spray pressure and propulsion speed, so that the cement-soil pile can be expanded to the designed length here;

[0028] (7) According to the diameter of the new cement-soil pile, control the flow and pressure of the cement slurry, and inject the cement slurry while stirring.

[0029] (8) After reaching the design position, the drill pipe is retracted. During this process, by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com