Method for reinforcing soft soil foundation at deep mixing pile

A technology for deep mixing piles and soft soil foundations, which is applied in the testing of foundation structures, sheet pile walls, foundation structure engineering, etc., can solve problems such as great difficulty in management, and achieve easy construction quality, low cost, and easy mixing evenly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

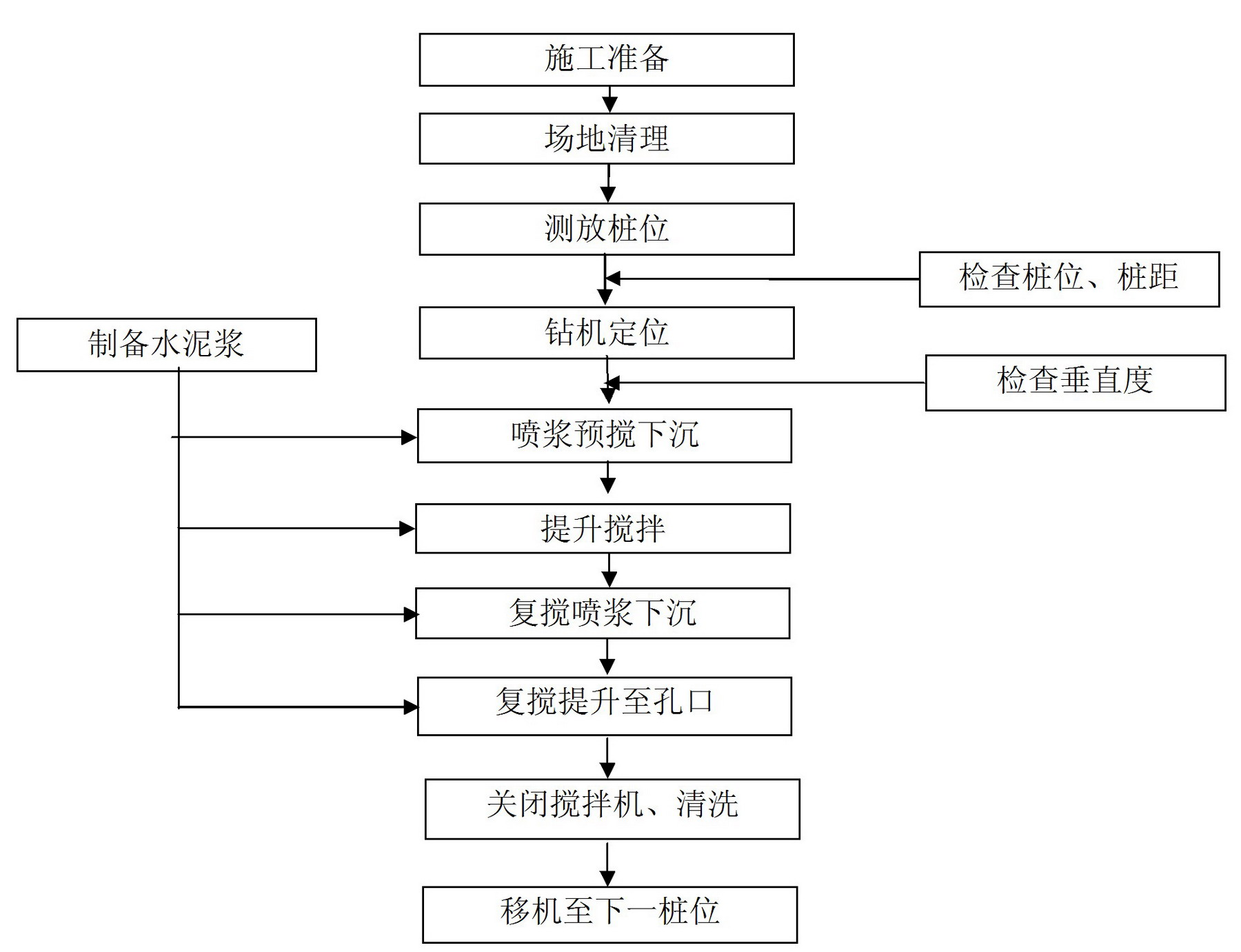

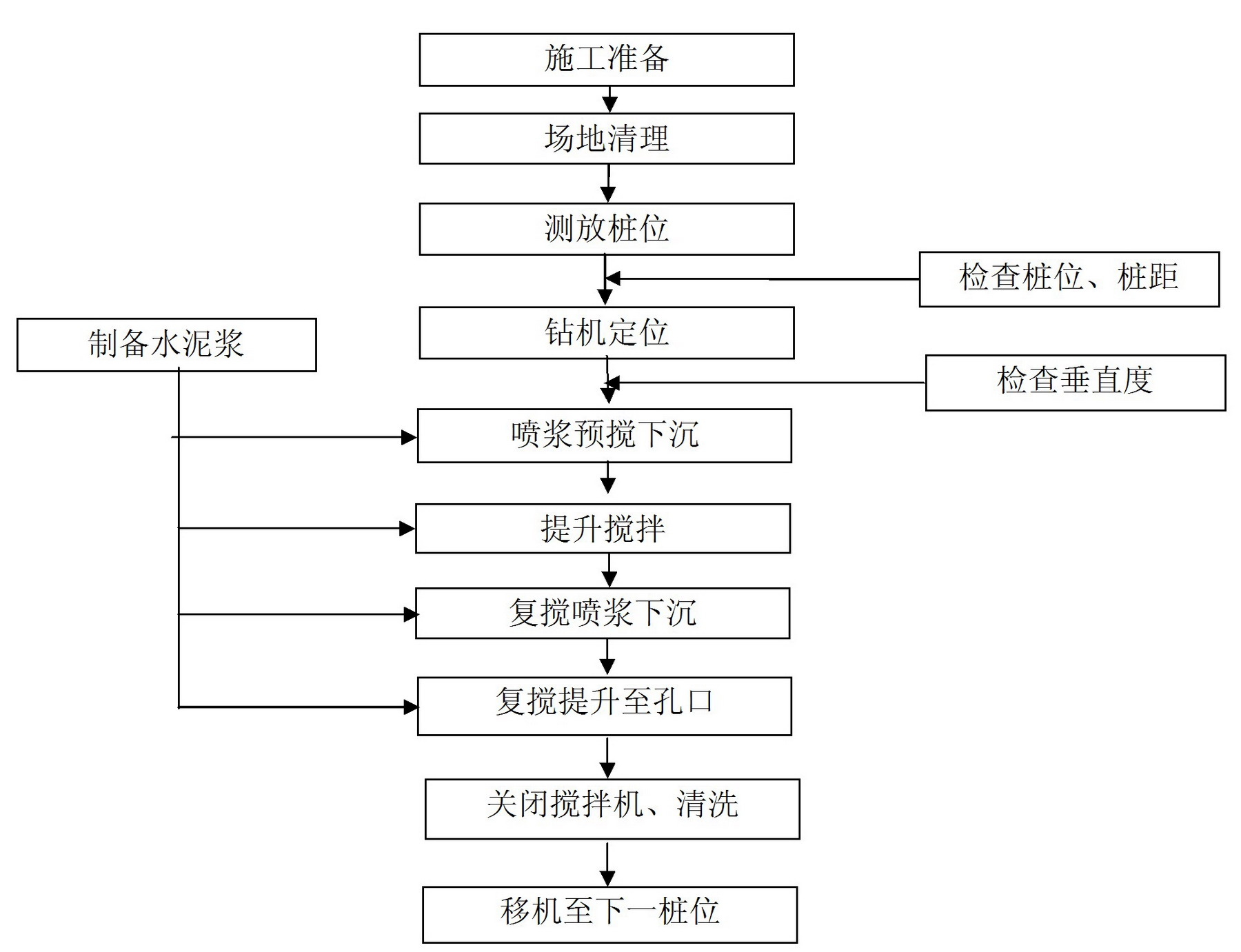

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Treatment of Soft Soil Subgrade in a Certain Section of Expressway Engineering

[0030] This section of the line passes through the embankment, and the maximum filling height is 17.8m. The basement is covered with loose soft soil, soft clay, silty clay, and gravel soil, with a total thickness of 10-12m. The peak ground acceleration in the section is 0.1g, and the characteristic period of the ground motion response spectrum is 0.45s. The scope of the mixing piles is located on the station line, which are 60 meters long, 136 meters wide, 120 meters long, and 46.9-104.7 meters wide.

[0031] Engineering geological conditions: The upper part of the area is loose soft soil or silty clay, which is widely distributed, and the engineering geological conditions are poor. It is soft clay, loose soft soil, silty clay, and coarse breccia; the thickness is 2.90-15m, the middle part is gravel soil, and the lower part is gneiss interbedded with marble. This soil layer has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com