Overall rigid waterproof system of building

A rigid waterproof and building technology, applied in building structure, construction, roof drainage, etc., can solve problems such as easy accumulation of water, leakage of roof nodes, and leakage of top nodes of parapet walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

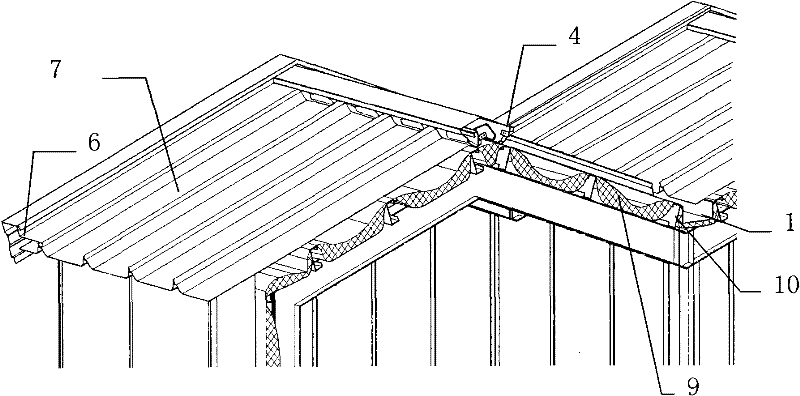

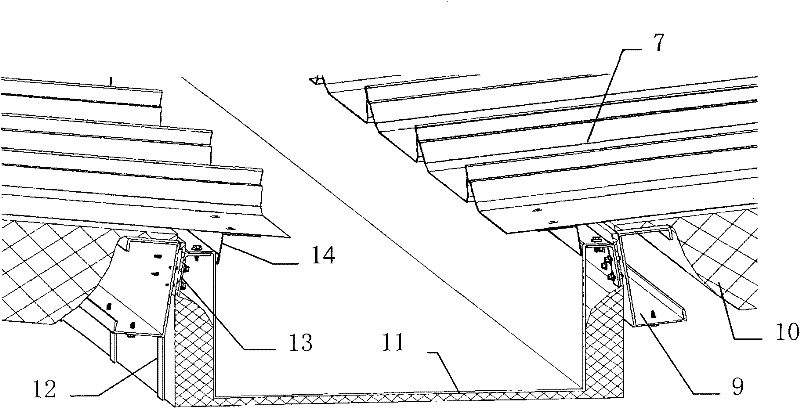

[0056] This embodiment is a factory building with double ridges and no parapet around the roof. Its steel structure sliding metal profiled roof system includes an indoor gutter unit 1 between columns with a slope of 0.5%, a ridge waterproof unit 4, and a gable side sliding support unit. 6 three parts, such as figure 1 As shown, among them, the indoor gutter 11 between the columns is made of bent 3mm thick ordinary steel plate, the indoor gutter conversion frame 12 and the gutter bracket 13 are both made of 3mm thick hot-dip galvanized steel strip; the roof flashing Plate 42, gable inner flashing parts 64, and gable outer flashing parts 65 are all made of 0.6mm color-coated galvanized steel sheets; Panels and profiled wall panels are made of 0.5mm color-coated galvanized steel sheets; insulation layer 10 is made of 100mm thick thermal insulation glass wool; roof purlins and wall purlins are all made of C-shaped steel purlins.

[0057] In this embodiment, the construction of t...

Embodiment 2

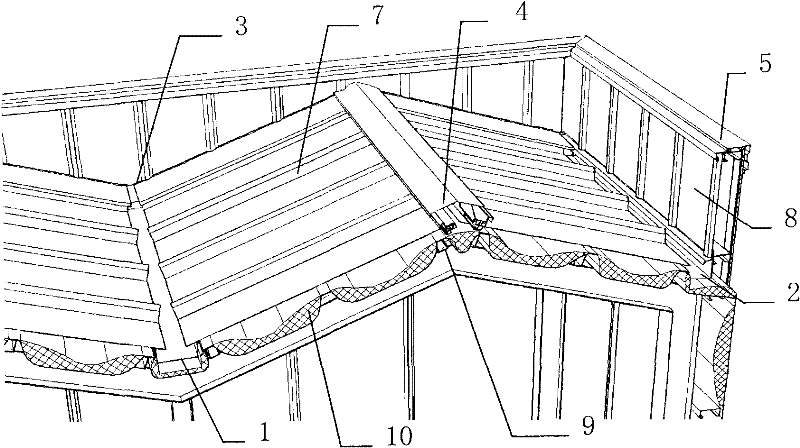

[0080] This embodiment is a building with double ridges and parapets and gables around the roof, such as automobile 4S shop buildings, etc., and its steel structure sliding metal profiled roof system includes an indoor gutter unit 1 between columns with a slope of 0.5%. The indoor gutter unit 2 at the side of the exterior wall with a slope of 0.5%, the waterproof unit 3 under the parapet, the waterproof unit 4 at the ridge, the waterproof unit 5 at the top of the parapet, and the sliding bracket unit 6 at the side of the gable are six parts, such as Figure 9 As shown, among them, the indoor gutter 11 between the columns and the indoor gutter 21 at the side of the outer wall are all made of bending ordinary steel plates with a thickness of 3mm, and the surface is sprayed with primer and topcoat twice; the indoor gutter conversion frame 12 and the roof The gutter brackets 13 are all processed by 3mm thick hot-dip galvanized steel strips; the outer wall side gutter conversion fra...

Embodiment 3

[0108] This embodiment is a factory building with double ridges and parapet walls around the roof building. The roof adopts a steel structure sliding metal profiled roof system, including an indoor gutter unit 1 between columns with a slope of 0.5%, and an exterior gutter unit 1 with a slope of 0.5%. Indoor gutter unit 2 at the side of the wall, waterproof unit 3 under the parapet wall, roof waterproof unit 4, waterproof unit 5 at the top of the parapet wall, five parts, such as figure 2 As shown, among them, the indoor gutter 11 between the columns and the indoor gutter 21 at the side of the outer wall are all made of bending ordinary steel plates with a thickness of 3mm, and the surface is sprayed with primer and topcoat twice; the indoor gutter conversion frame 12 and the roof The gutter brackets 13 are all processed by 3mm thick hot-dip galvanized steel strips; the outer wall side gutter conversion frame 22 and the outer wall side gutter brackets 23 are also processed by 3m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com