Device and method for removing molten steel slag inclusion in continuous casting tundish

A continuous casting tundish and tundish technology, which is applied in the direction of casting molten material containers, casting equipment, manufacturing tools, etc., can solve the problems of small quantity, large pores of air curtain permeable bricks, large diameter of argon bubbles, etc., and achieve low production cost , high bubble density, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

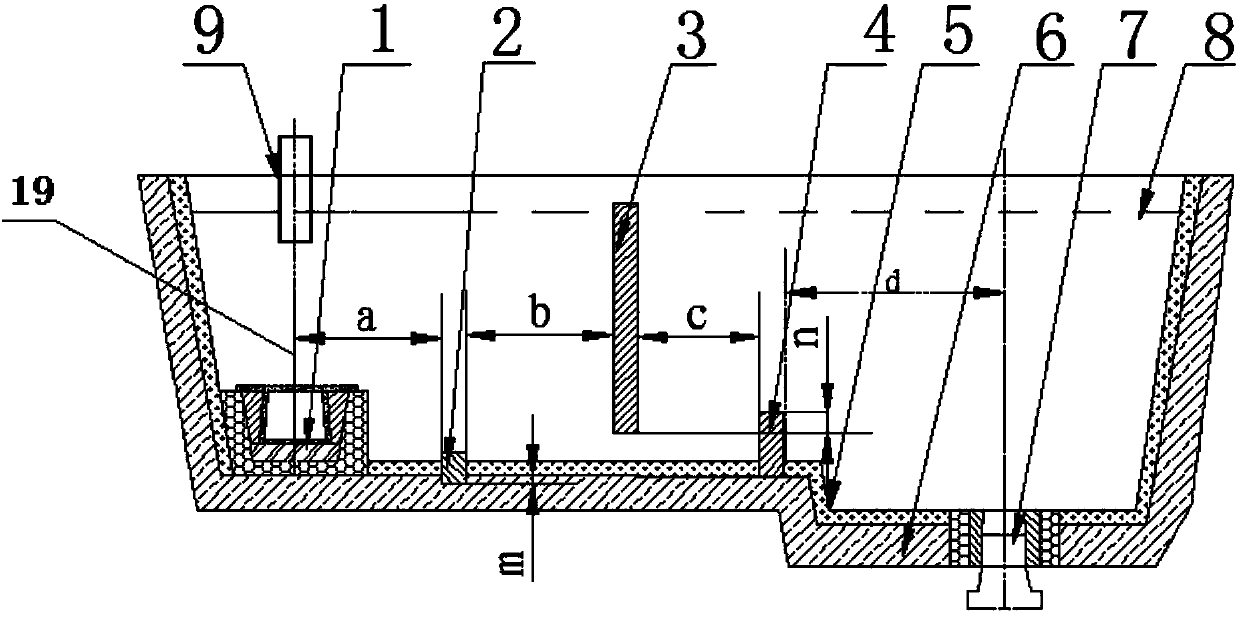

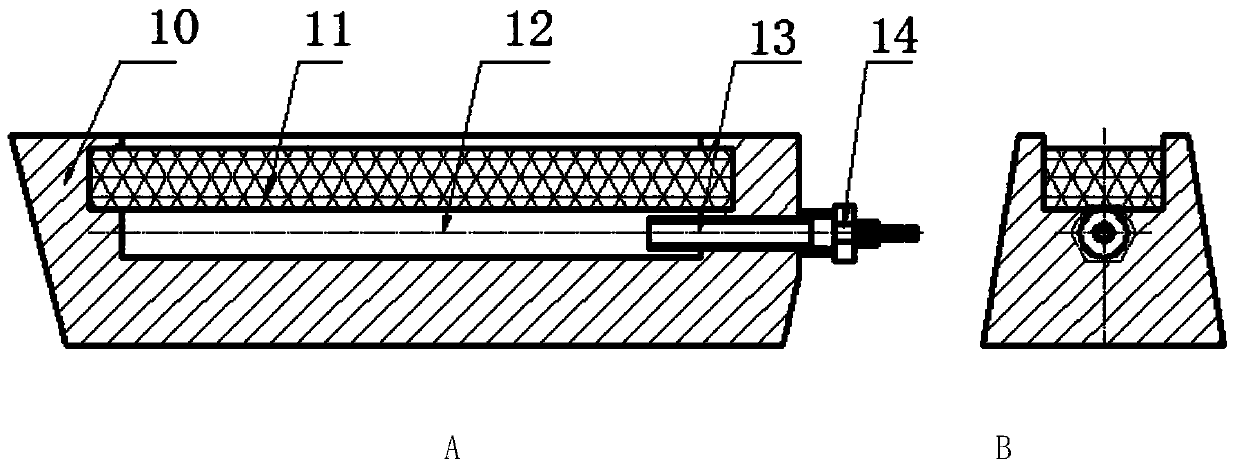

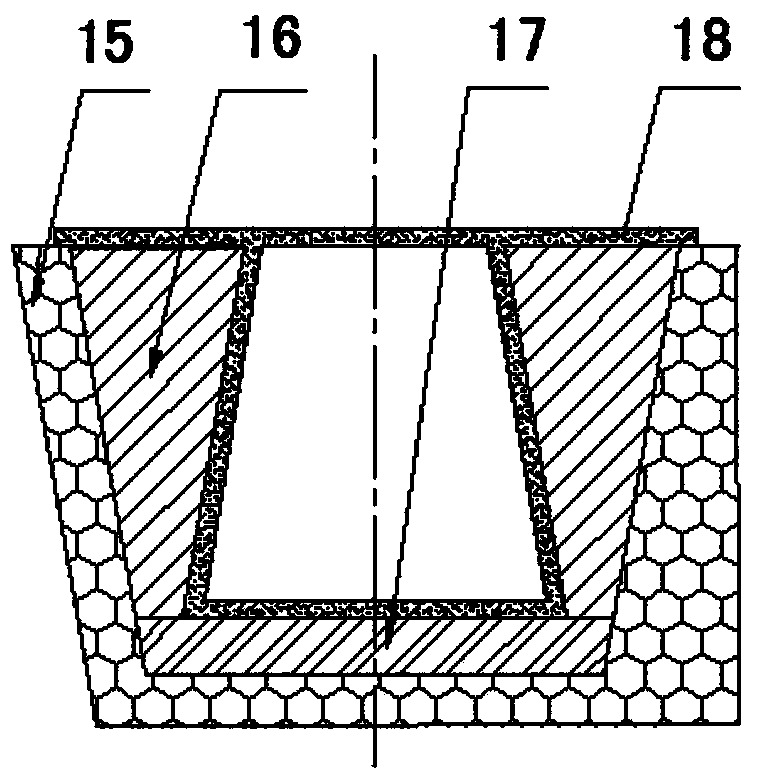

[0038] A device for removing molten steel inclusions in a continuous casting tundish, with a structure such as Figure 1-Figure 5 As shown, it includes turbulence controller 1, air curtain permeable brick 2, retaining wall 3 and retaining dam 4, turbulence controller 1 is installed on the inner side of the working lining of the tundish injection impact zone, and its longitudinal centerline is the same as the length of the tundish. The center line of the nozzle 9 coincides, the two ends of the retaining wall 3 are fixed on the working lining 5 of the tundish wall, the bottom end of the retaining dam is fixed on the working lining 5 at the bottom of the tundish, and the retaining wall 3 is located at the turbulence control Between the device 1 and the dam 4, the air curtain permeable brick 2 is located between the turbulence controller 1 and the retaining wall 3, and the bottom end is fixed on the permanent lining at the bottom of the tundish. The longitudinal centerline of the t...

Embodiment 2

[0044] The device for removing molten steel inclusions in the continuous casting tundish as described in Example 1, the difference is:

[0045] The horizontal distance a between the longitudinal centerline of the turbulence controller 1 and the air curtain permeable brick 2 is 600 mm, the horizontal distance b between the air curtain permeable brick 2 and the retaining wall 3 is 700 mm, and the horizontal distance c between the retaining wall 3 and the retaining dam 4 is 600mm, and the horizontal distance d between the retaining dam and the upper nozzle of the tundish is 1000mm.

[0046] The depth m of the bottom end of the air curtain permeable brick 2 embedded in the permanent lining 6 at the bottom of the tundish is 30mm.

Embodiment 3

[0048] The device for removing molten steel inclusions in the continuous casting tundish as described in Example 1, the difference is:

[0049] The horizontal distance a between the central line of the turbulence controller 1 and the air curtain permeable brick 2 is 400mm, the horizontal distance b between the air curtain permeable brick 2 and the retaining wall 3 is 200mm, and the horizontal distance c between the retaining wall 3 and the retaining dam 4 is 200mm, and the horizontal distance d between the retaining dam and the upper nozzle of the tundish is 1200mm.

[0050] The depth m of the bottom end of the air curtain permeable brick 2 embedded in the permanent lining 6 at the bottom of the tundish is 18mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com