Single-rail window wiping machine

A window cleaning machine and monorail technology, which is applied in the direction of cleaning machinery, machine parts, building structure support, etc., can solve the problems of narrow roof space, insufficient space to arrange two rows of tracks, and the inability of window cleaning machines to install and work. , to achieve the effect of good operation stability, compact structure and flexible steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

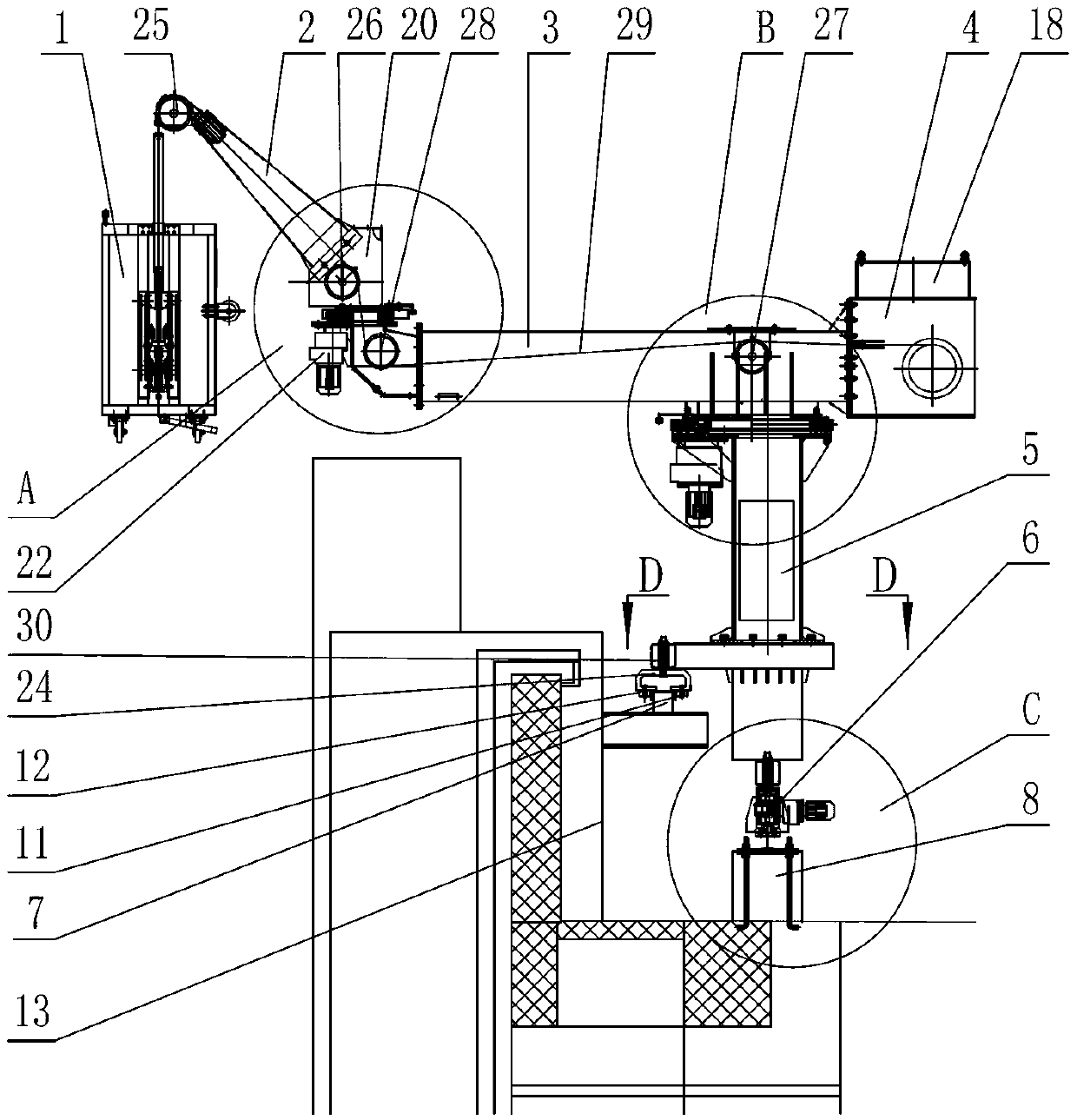

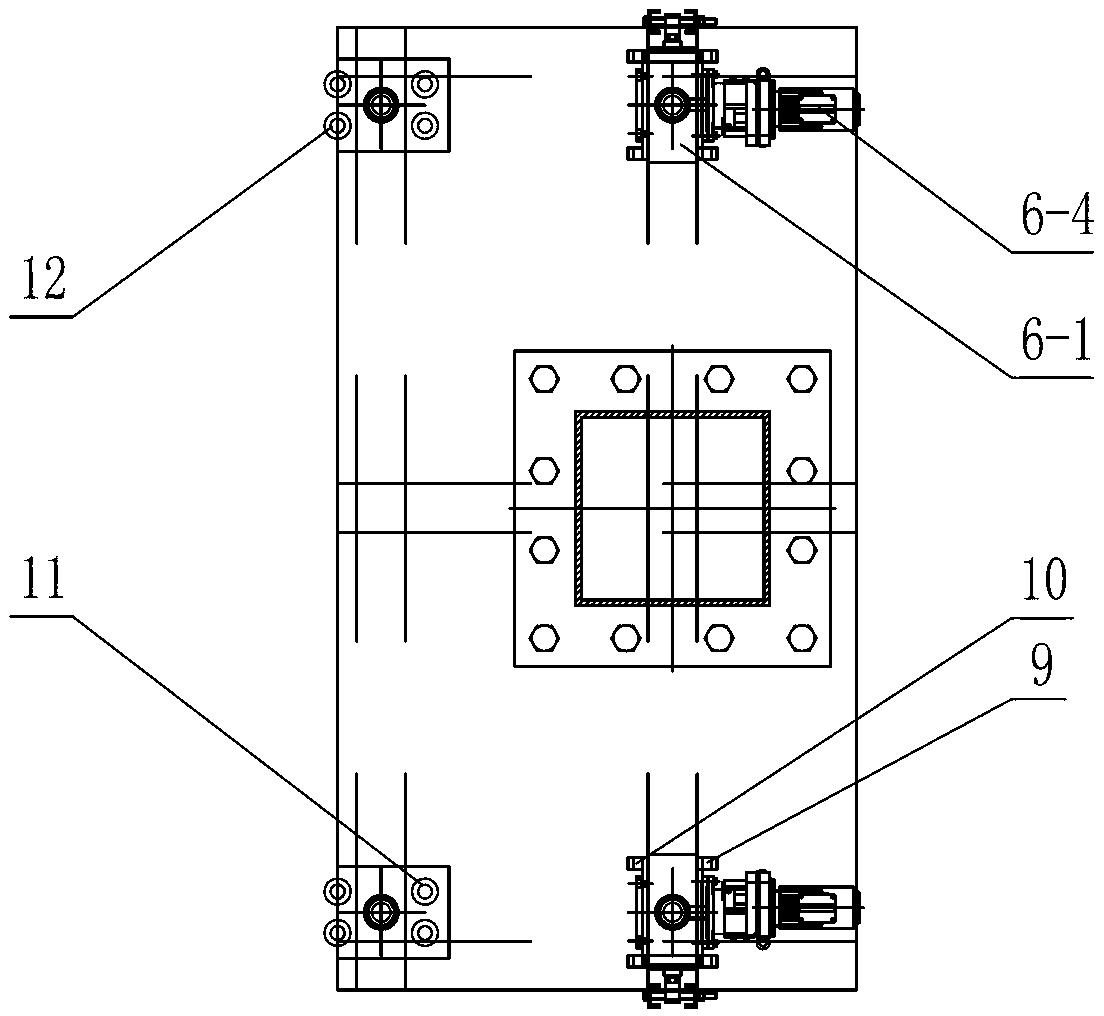

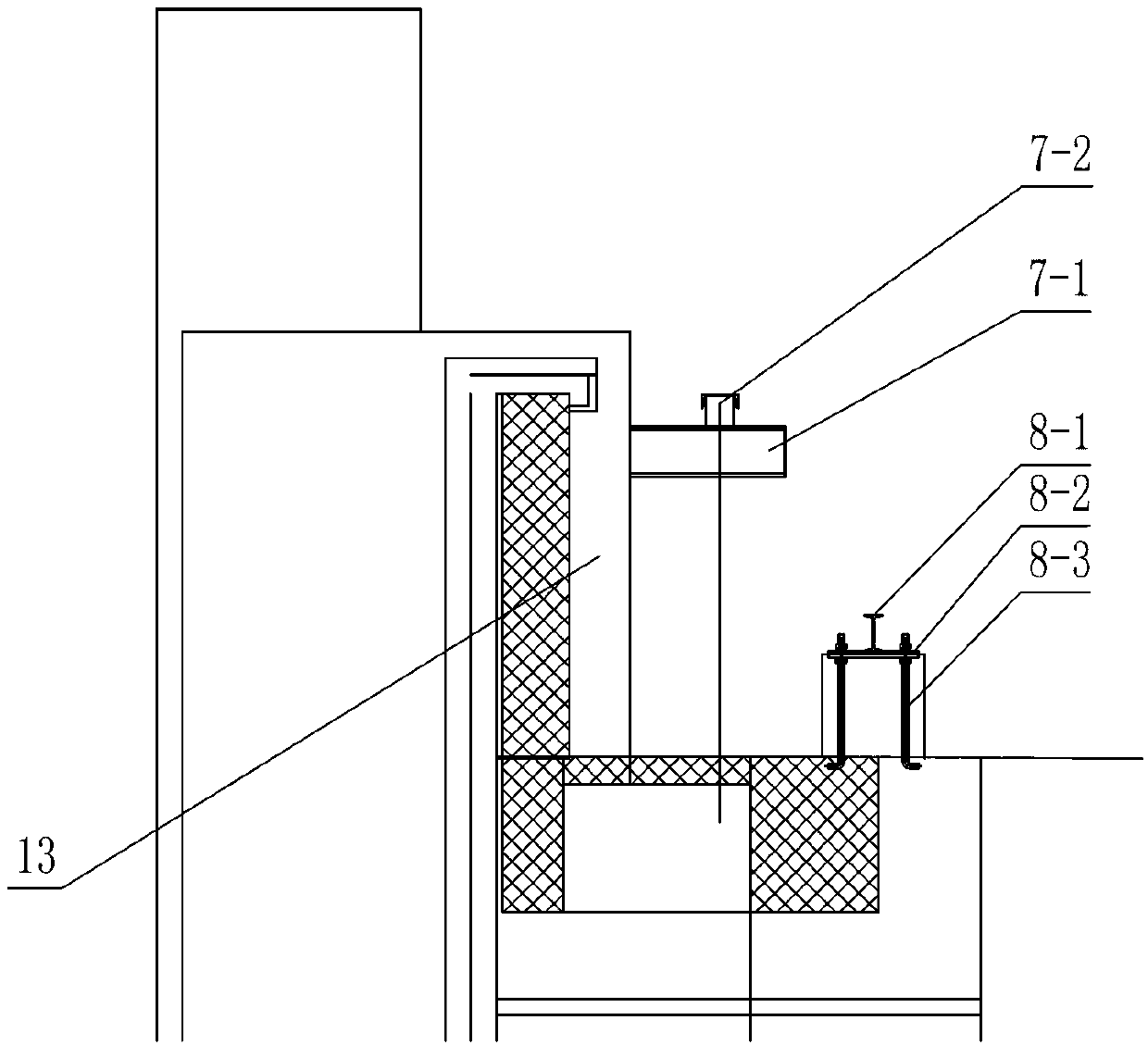

[0020] The present invention will be further described below in conjunction with specific drawings.

[0021] Such as Figure 1 ~ Figure 3 As shown: the monorail window cleaning machine includes a gondola 1, a dovetail arm 2, a cross arm 3, a winch 4, a column 5, a traveling mechanism 6, a traveling seat 6-1, a roller shaft 6-2, a traveling roller 6-3, Travel motor 6-4, anti-tilt track mechanism 7, I-shaped steel column 7-1, channel steel anti-tilt track 7-2, driving track mechanism 8, I-shaped steel track 8-1, track backing plate 8-2, pre- Buried fixing parts 8-3, inner horizontal wheel 9, outer horizontal wheel 10, inner anti-tilt wheel 11, outer anti-tilt wheel 12, parapet 13, first slewing bearing 14, first gear 15, first slewing motor 16. Second gear 17, counterweight 18, second slewing bearing 19, slewing base 20, third gear 21, second slewing motor 22, fourth gear 23, anti-tilt seat 24, first pulley 25, second Pulley 26, the 3rd pulley 27, the 4th pulley 28, wire rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com