Broad-band piezoelectricity oscillating generating set

A piezoelectric power generation, broadband technology, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. To achieve the effect of maximizing power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

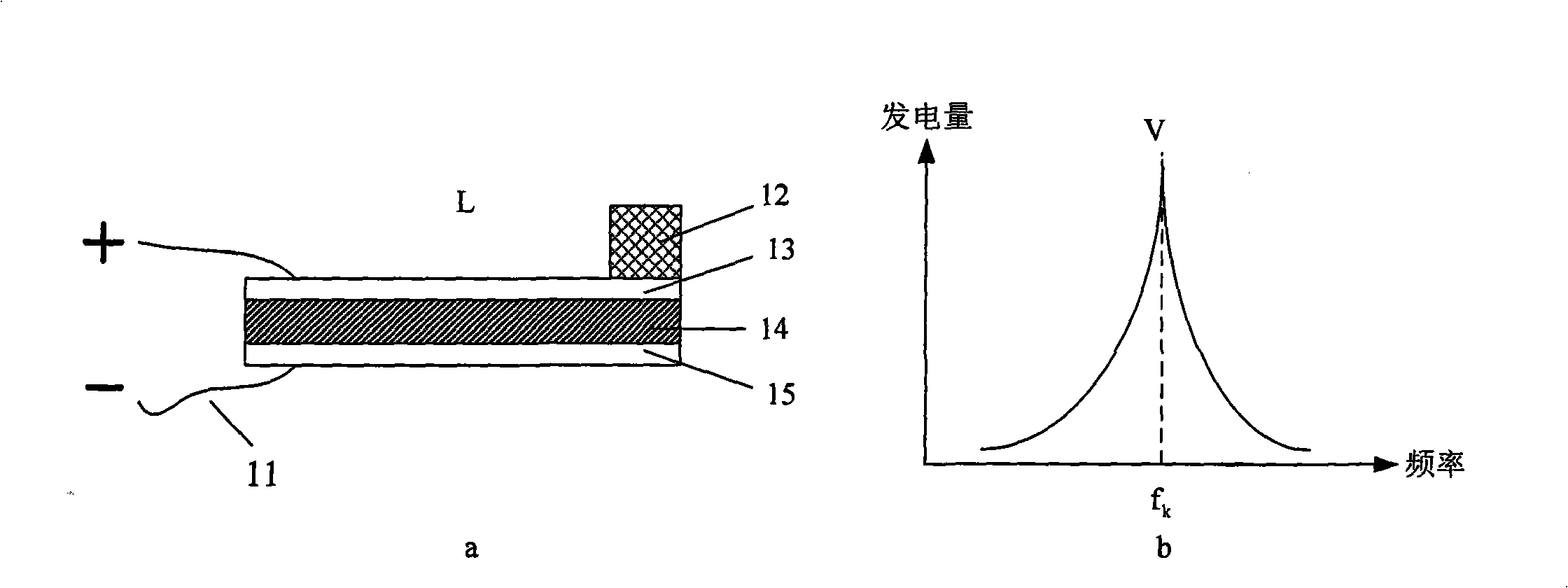

[0018] figure 1 a describes the structure of the prior art single cantilever beam L, the single cantilever beam L includes a piezoelectric transducing element 14, a lead wire 11, a metal block 12, a positive electrode 13 and a negative electrode 15, the piezoelectric transducing element 14 and two electrodes 13 and 15 are stacked and arranged, and the piezoelectric transducer element 14 is located between the positive electrode 13 and the negative electrode 15, similar to a sandwich structure. The lead wire 11 is located at the fixed end of the cantilever beam L, and is used to derive positive and negative charges respectively, and the metal block 12 is located at the free end of the cantilever beam L, so that the single cantilever beam L can generate the maximum amplitude when vibrating. figure 1 b for figure 1 The power generation-frequency curve of a single cantilever beam shown in a, the horizontal axis represents the frequency of external vibration, and the vertical axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com